Search

Search

Search

Search

Unconventional

Eliminate the cost, time, and risk of plug millout intervention

North Dakota, Williston Basin

The operator wanted to remove the risk of intervening in a depleted wellbore when milling out composite plugs.

The customer was able to successfully flow back the wellbore and start production without issue or the need for a wellbore cleanout intervention.

A major operator drilling in the Bakken and Three Forks formations in the Williston Basin was concerned about depleted reservoir conditions due to close well spacing. The operator needed a solution that would eliminate the wellbore intervention step required to clean out traditional composite frac plugs. The wellbores consisted of 4 1/2-in. production liners averaging 10,000 feet total vertical depths with 10,000-foot horizontal sections. On a previous well, the customer experienced a costly incident where the millout string and bottomhole assembly got stuck due to the depleted reservoir conditions, requiring an extensive fishing job.

Halliburton recommended dissolvable Illusion frac plugs for the plug-and-perforate operation to resolve the customer’s intervention concern. Upon successful completion of the 35+ stages, which required no special wireline installation equipment or pump-down procedures, the plugs dissolved, intervention was eliminated and flowback efforts were uninterrupted. The well was put onto production, achieving initial flowback, and sustained months of production that matched expectations.

For upcoming high-density well-spacing trials, the operator primarily wanted to remove the risk of intervening in the depleted wellbore when milling out composite plugs. Those risks, unmitigated, can put higher-density drilling programs at risk due to the steep costs and time delays created when millout challenges are encountered.

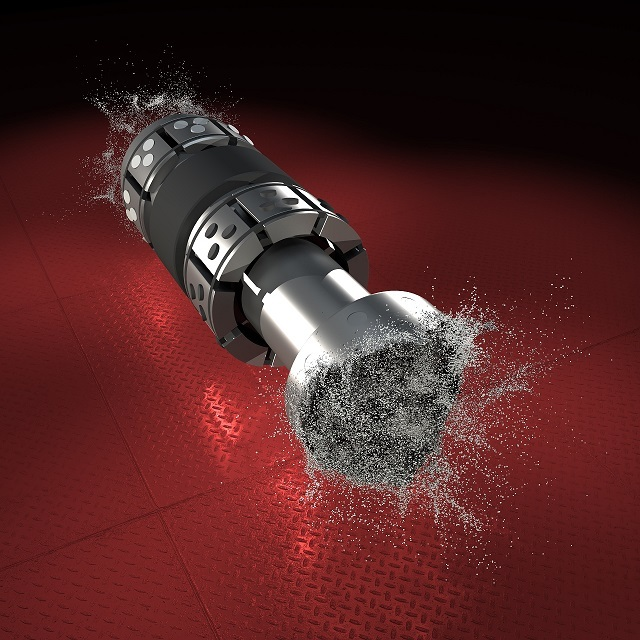

This high-performance frac plug provides zonal isolation for pump-down applications during wellbore stimulation, and combines Halliburton’s industry-leading frac plug designs with the most advanced dissolvable metal and rubber materials. The large-bore ID allows operators to produce through the plug while it remains in the wellbore and begins the dissolution process immediately following fracturing.

days of intervention

saved

issues with pump-down installation and fracturing

The Illusion dissolvable frac plugs were pumped down and set without issue during the fracturing operations. Run-in-hole speeds exceeding 400 feet per minute through the horizontal were achieved — a conservative, but typical application of Illusion plug efficiency and reliability.

The customer was able to successfully flow back the wellbore and start production without issue or the need for a wellbore cleanout intervention. This alone saved a minimum of $250,000 in costs typically attributed to a millout operation and, more importantly for this application, helped eliminate the risk and cost associated with their previous millout experience.

Because Halliburton Illusion frac plugs completely eliminated the need for intervention, the application was a success for the customer. Days were saved bringing the well onto production, boosting the overall economic performance of these well projects.

Frac Plugs

The Illusion frac plug not only helps alleviate the cost and time of plug mill-out operations, but it also helps remove the risk associated with coiled tubing.

Download Data Sheet

This high-performance frac plug provides zonal isolation of the wellbore during stimulation treatment and customized dissolution times