Search

Search

Search

Search

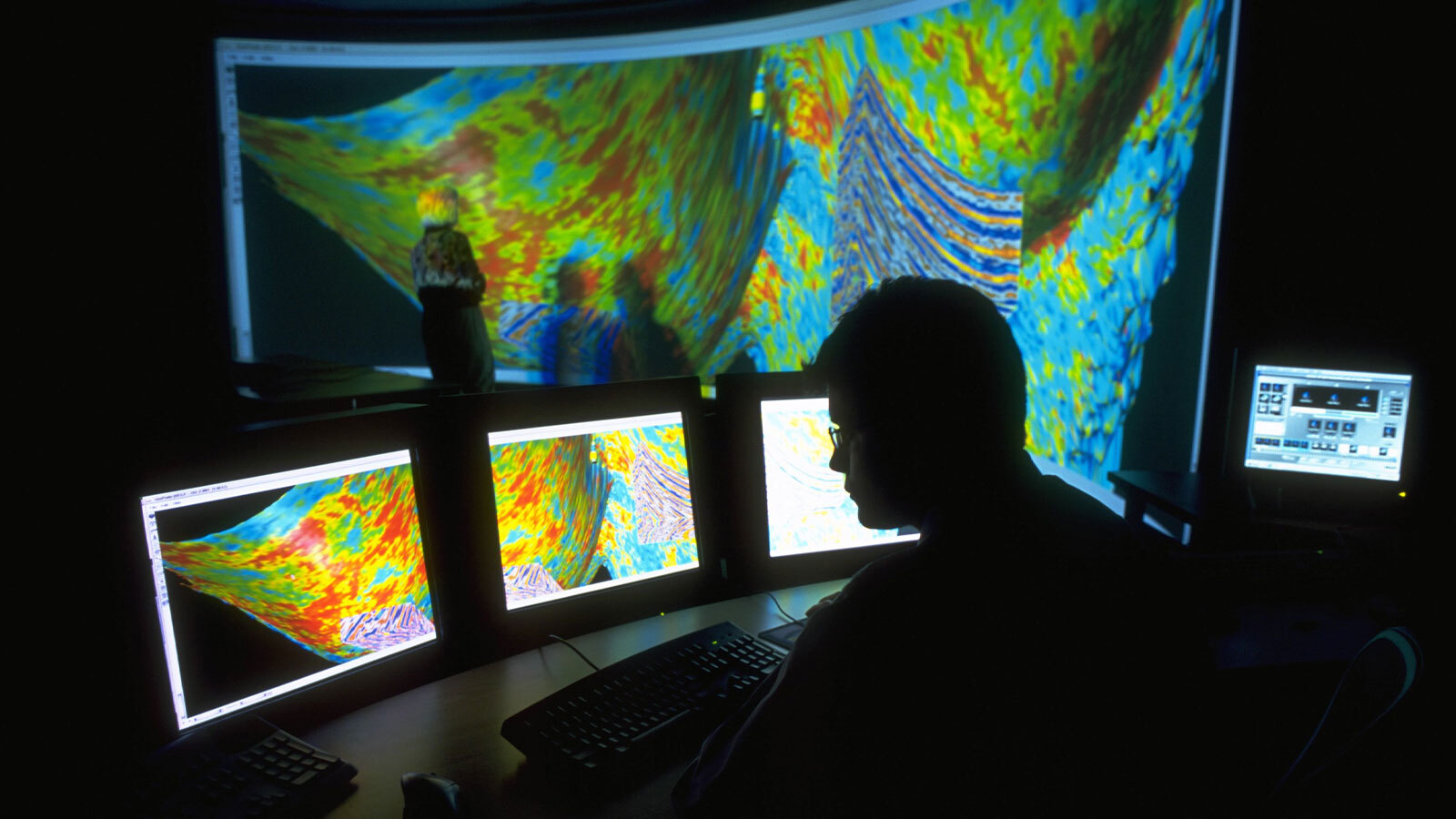

New service execution benchmark set in ultradeepwater exploration campaign

Download PDFDeep Water

Find fracture and closure pressure in a challenging ultradeepwater environment

Ghana, West Africa

Aker Energy has recognized Halliburton Wireline as a benchmark for service quality and execution in an ultradeepwater exploratory campaign in Ghana, West Africa. The campaign started in late 2018 and was completed summer 2019, concluding the drilling and formation evaluation of five exploration wells and two sidetracks. During the campaign, Halliburton Ghana, with the support of its region and global team, listened and responded to deliver an engineered solution to achieve Aker Energy’s objectives in a challenging ultradeepwater environment with water depths reaching up to more than 10,000 feet deep. Located about 115 nautical miles offshore from the coast of Ghana, this exploratory project is part of the deepest offshore oil wells in Ghana.

Aker Energy needed to find fracture and closure pressure of the formation with a microfracture technique in a 12.25-in. open hole. An attempt was performed in 2012 by a competitor without success, which lessened the customer’s confidence in the wireline solution. At the time, Halliburton had only performed two previous microfracture operations in a 12.25-in. hole size, neither of which was in Ghana.

Additionally, Aker Energy decided to drill a sidetrack well after completing the main bore, with deviation up to 62° towards the target depth. The wireline program consisted of four runs: an MRIL®-XL service, Quint Combo with Xaminer® Sonic Imager tool (XSI), Reservoir Description Tool (RDT™) sampling, and the Xaminer® Rotary Sidewall Coring service. Simulations were performed, and none of the four runs was able to achieve total depth (TD) with conventional wireline conveyance.

Finally, in the beginning of the project, the customer faced several difficulties when trying to exchange hundreds of MB of data from the wireline data acquisition among the stakeholders based in the drillship, at the customer’s office in Accra, and in Oslo, Norway at the customer´s headquarters. The customer process required different levels of data review, starting just after the operation in the drillship with the wellsite geologist and wireline witness, then in the customer’s office in Ghana, and after these first two levels, a further review in Oslo by the senior geologist.

Halliburton delivered several new and innovative solutions during the campaign. To address the fracture and closure pressure, an RDT™ Straddle Packer Section (SPS) microfracture operation was performed inside a 12.25-in. hole for the first time in Ghana. For the sidetrack on the highly deviated wellbore, Halliburton proposed the use of a “tool taxi” conveyance system as an alternative to pipe-conveyed logging. Simulations were performed and confirmed the potential of achieving TD for all four runs using tool taxi conveyance.

A data management solution was tailored to address the customer’s need for data sharing via the XSpace™ data management platform and the creation of different levels of activities within each well. This allowed the customer to implement their data workflow with different levels of reviewers.

Deployed with success

of rig-time savings

USD saved

For the microfracture operation, after 17 hours of pumping with the SPS on a sand formation with a permeability of 0.077 mD/cp and an average pumping rate of 2 cc/s, a water sample was taken and contained into two PVT bottles. Aker Energy was able to confirm significant additional reserves based on the information acquired while also successfully finding out fracture and closure pressure in sand and shales formations.

In the case of the highly deviated sidetrack, the system was mobilized to Ghana in a short time frame, and the four runs were deployed with success, executing the full logging program. Wireline conveyance on this highly deviated hole significantly minimized rig time, compared to pipe-conveyed logging operations, saving an estimated minimum of 80 hours of rig time valued at approximately USD 3.3 million.

The XSpace solution significantly improved data delivery after the first logging operation.

Aker Energy’s operations geologist, after concluding the last wireline formation evaluation operation in July 2019, noted:

“Please pass on my praise to all involved for the exemplary performance of logging operations at Nyankom-1X. To see 100% operational efficiency in 5 out of 6 wireline runs…to me, is almost unheard of. Also, with over a day shaved off expected duration of operations, a new benchmark is reached. I would also like to praise the whole wireline operation, which can be considered nothing but a success. The effort that the whole crew has put into it is much appreciated and recognized by the whole team onshore. We have managed to obtain even the most difficult data (sampling in below 1mD rock, fracking the permeable sandstones), and the tools have generally impressed with the robustness and durability.”