Search

Search

Search

Search

Three simultaneous dual drilling operations reduce well time and attain world-first record

Download PDFUnconventionals

Successfully drill two wellbores at three different proximal locations

North Sea, Offshore Norway

Collaborated with Aker BP to conduct:

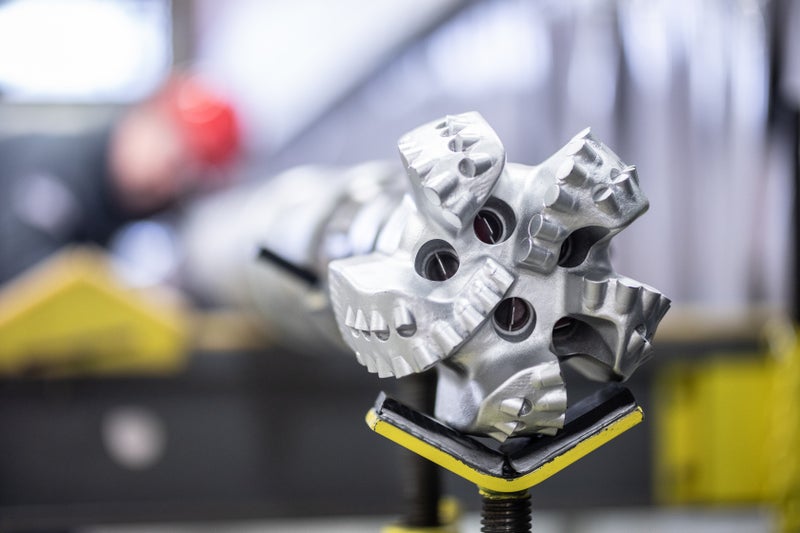

In collaboration with Aker BP, Halliburton Sperry Drilling planned and drilled two wellbores at three different proximal locations in the North Sea, offshore Norway near Stavanger. A prerequisite for each location was to first drill a pilot hole to evaluate the presence of shallow gas. Typically, the conductor hole is drilled before a pilot hole, followed by the opening of the pilot hole for running the outer-diameter (OD) casing.

The deepwater rig had a dual derrick design, with full drilling capacity in both derricks. Since the derricks’ well centers were approximately 33 feet (10 meters) apart, it was decided in the planning phase of pre-operations to drill two wells simultaneously: the “pilot-hole shallow-gas” wellbore and the “main” wellbore. While this initiative was thought to be efficient and time saving, it could also potentially introduce risk factors.

A thorough health, safety, and environmental (HSE) review was conducted to ensure a risk-mitigated environment, reduced to an acceptable level, such that performing simultaneous operations (SIMOPS) of this magnitude (and in close proximity to a neighboring wellbore) was feasible.

Teamwork and collaboration between Aker BP and Halliburton were key to the success of this project. The following tasks were accomplished:

Drilling two wellbores at multiple locations requires a significant amount of resources – not only in execution, but also in planning. Aker BP and Halliburton held planning discussions on how best to utilize their respective resources, which resulted in an executable timeline. Logistics were also carefully coordinated, so that equipment was loaded onto the rig for the next location, hile it was completing plug-and-abandon (P&A) operations at another location. This equipment included customized bottomhole assemblies (BHAs) and all the “standard” services, such as fluids and casing. It was also necessary to augment the number of personnel in certain departments to enable testing, handling, and building equipment prior to arriving at the first location to execute dual drilling operations.

Due to the increased volume of equipment that was present on the rig, and the forward plan of batch drilling top holes and pilot holes on other locations, an equipment utilization plan was designed and implemented. This plan allowed the three dual drilling operations to be carried out with the minimum amount of equipment.

The three simultaneous dual drilling operations attained a world-first record. Thanks to this coordinated effort, thorough planning, and flawless execution, the following wellbore sizes and sections were successfully drilled at their respective locations:

This major achievement was also distinguished by zero HSE issues, and an average savings of 1.5 days over conventional operations per dual drilling operation, equating to USD 1.2 million saved, helping Aker BP maximize the value of its assets.

Days saved

Health, safety, and environmental (HSE) issues

USD saved

Halliburton delivers drilling performance to increase asset recovery, improve wellbore quality, and reduce overall well construction costs.