Search

Search

Search

Search

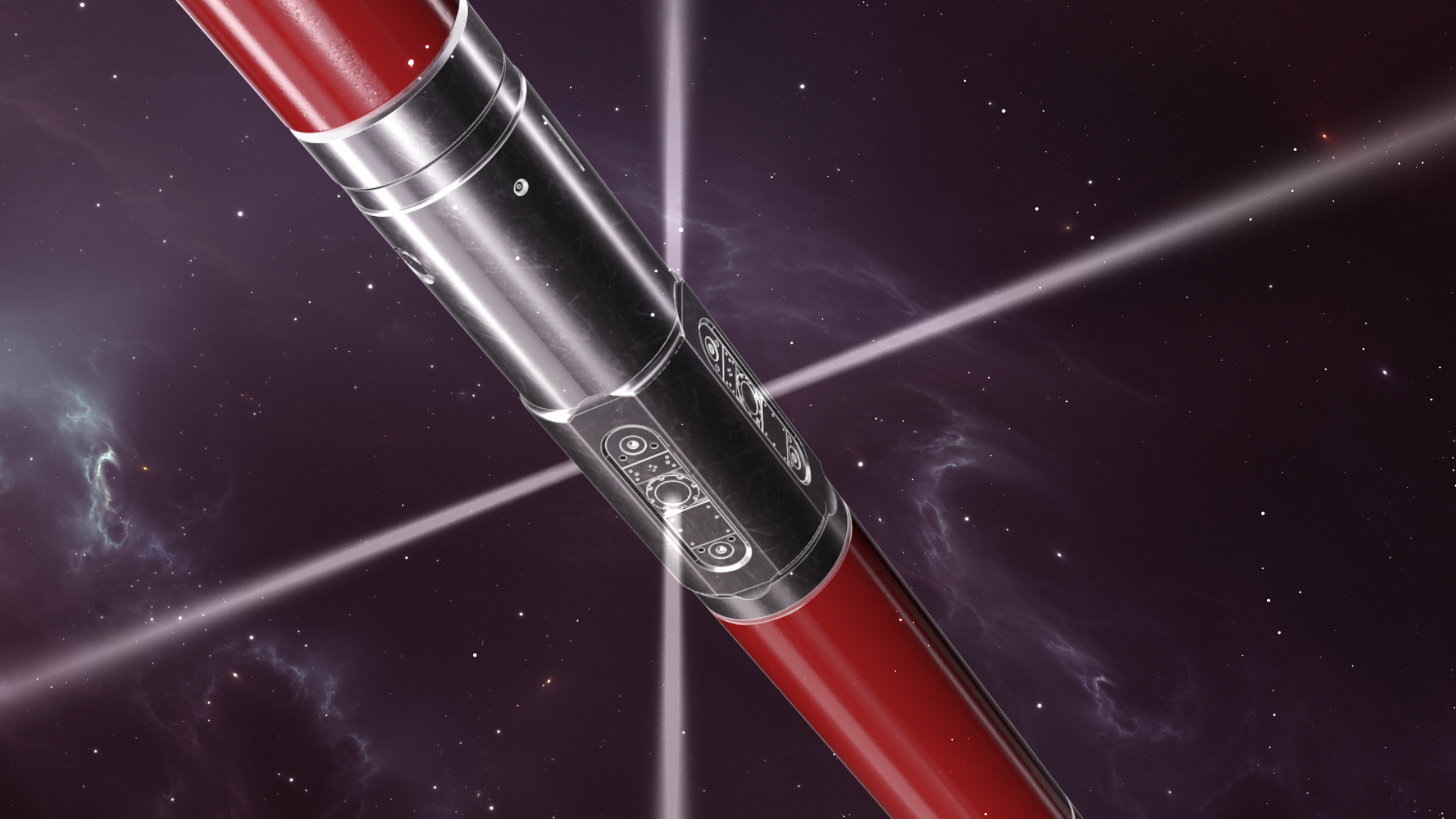

The PixStar ultrasonic imaging service provides high resolution images in oil- and water-based muds, showing fractures, geological features, and more.

SPWLA Petrophysics Journal / January 2020

PixStar is a logging-while-drilling technology that provides high-resolution images, regardless of the mud type used.

READ THE ARTICLEKuwait / April 2020

Kuwait Oil Company used PixStar technology to identify bed boundaries and borehole breakout in a 6-inch wellbore.

Read Case StudyMiddle East / November 2019

PixStar imaging identified 255 reservoir features, including 126 bed boundaries, 63 fractures, 50 breakouts, and 16 high-angle features.

Read Case StudyUltrasonic transducers

Angle increments around circumference

Pulses per second

Texas / December 2019

High-resolution imaging enabled borehole condition monitoring while drilling and identified zones of borehole enlargement.

Read case studyThe PixStar high-resolution ultrasonic imaging service takes high-quality images in oil- and water-based mud, giving operators the information to make informed drilling decisions in real time. The logging-while-drilling (LWD) service measures borehole sizes and shapes, showing fractures, faults, and more.

Texas/December 2019

PixStar imaging showed fractures and bed boundaries in a near-horizontal wellbore, removing the need for separate wireline run.