Search

Search

Search

Search

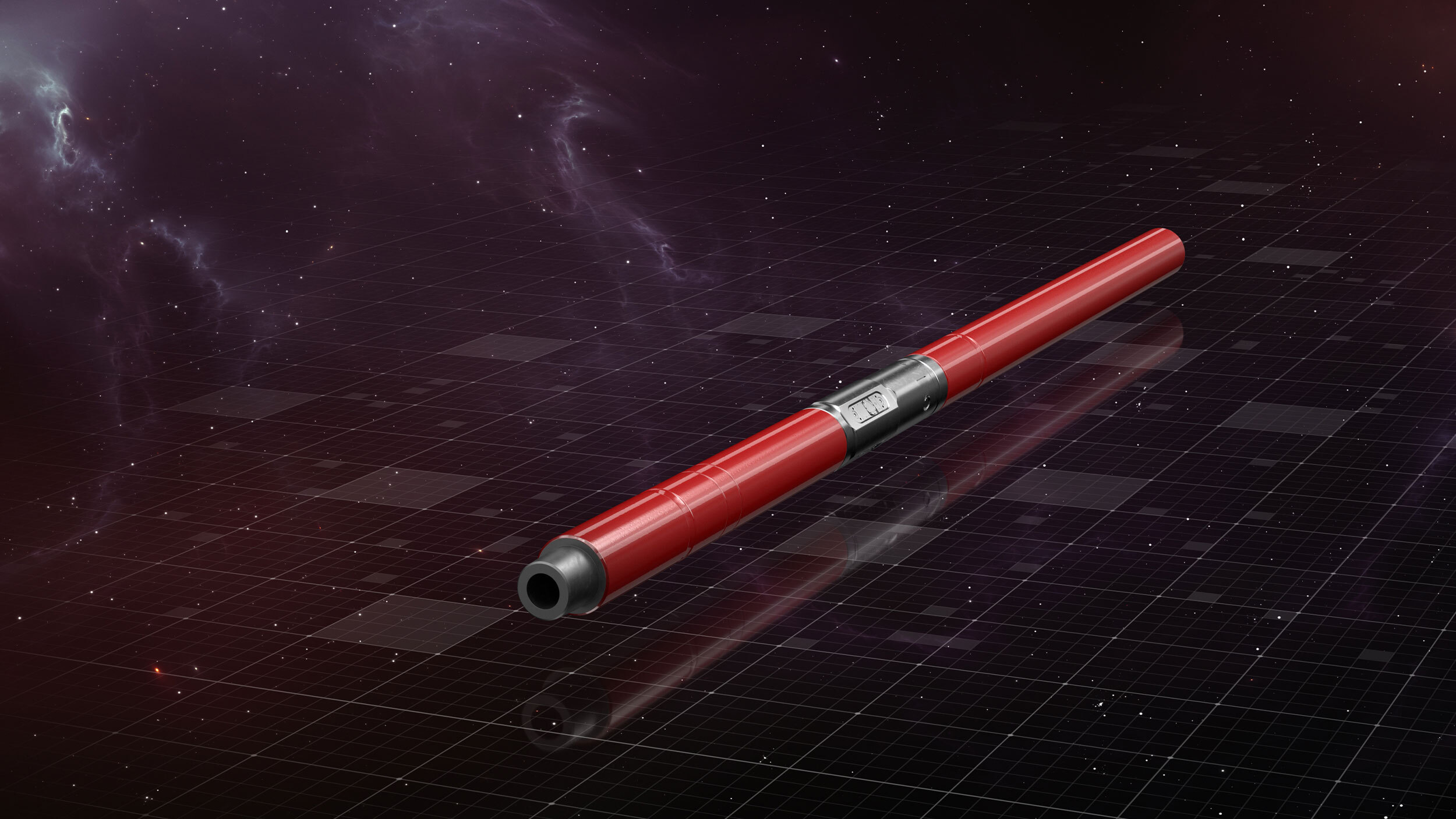

The BaseStar service helps operators fully understand the bottom hole assembly (BHA) position and dynamics in all drilling environments.

The BaseStar service takes pumps-off static surveys for reduced well time and accurate geometric wellbore positioning. High-frequency, continuous inclination and azimuth measurements enable the automated drilling service from Sperry Drilling to adapt to downhole uncertainty and accurately place the well. This directional data also supports our survey management services that further improve accuracy by correcting for localized environmental influences.

Real-time hole shape and annular-pressure measurements allow ongoing evaluation of wellbore stability and effective control of the mud program to protect formation integrity and mitigate hole problems. In the pumps-off mode, the service measures the minimum, maximum, and average pressures during non-circulating periods and transmits the results to the surface when circulation resumes.

Downhole torque, weight, and vibration measurements drive real-time decisions for improved drilling efficiency and optimized performance. This comprehensive sensor package allows operators to mitigate the risk of tool damage, monitor and efficiently transfer weight and torque along the drillstring, manage drilling dysfunction, and eliminate non-productive time contributing to a quicker well delivery.

Real-time bore and annular pressure measurements allow monitoring of equivalent circulating density and enable rapid decisions to modify drilling and drilling-fluid parameters or operating procedures to improve hole cleaning efficiency and avoid pack-offs.

The BaseStar service provides high-resolution gamma-ray logs and gamma-ray borehole images to enhance well placement and further reduce the geological uncertainty of the reservoir.