Search

Search

Search

Search

Integrated expandable liner hanger for multilateral applications

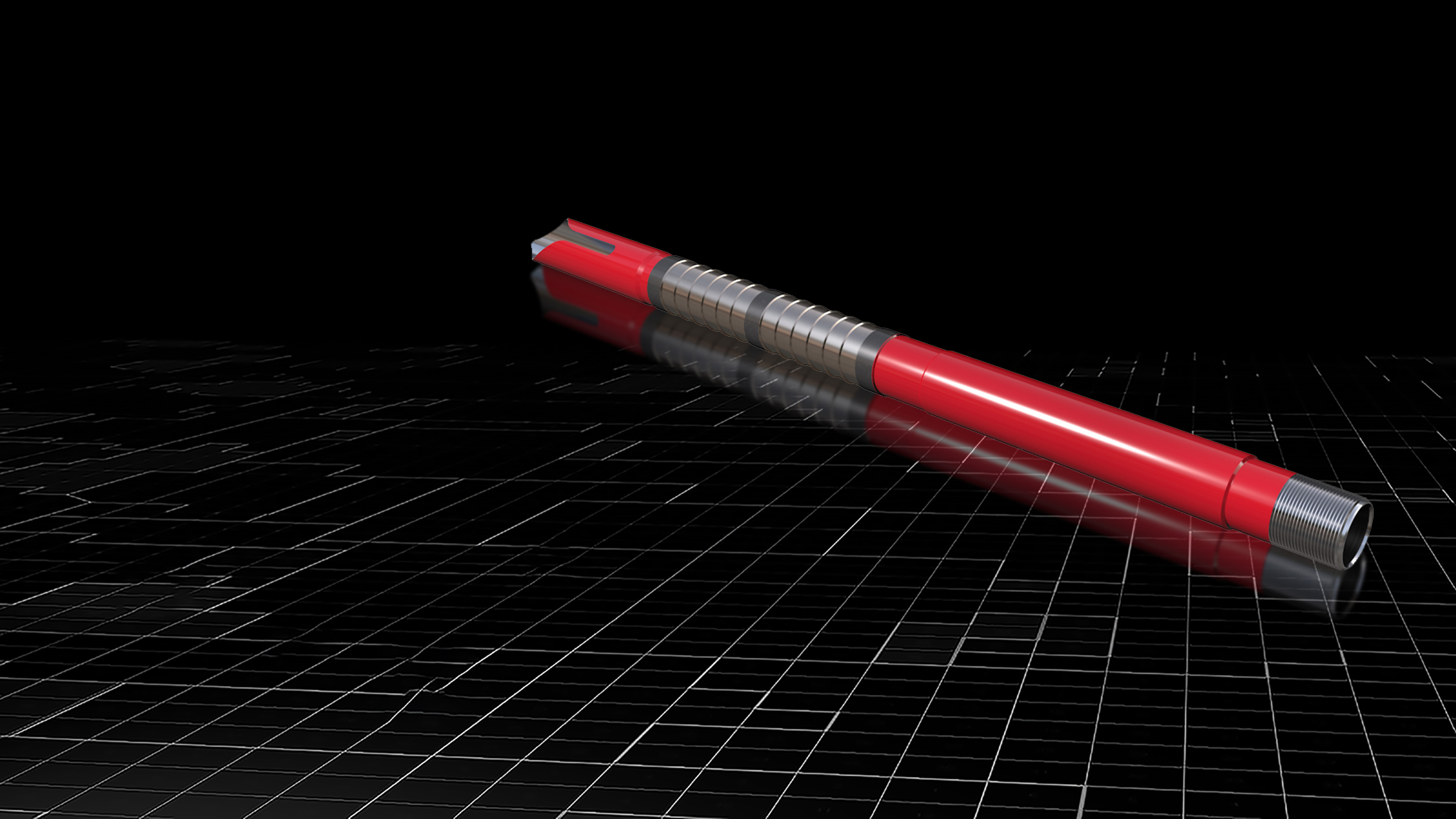

Talk to an expertThe XtremeGrip MLT expandable liner hanger (ELH) system offers an integral multilateral self-orienting profile to allow the hanger to provide positive depth and orientation control in multilateral wells for offshore and onshore applications.

The high-performance XtremeGrip MLT system offers a compliant metal-to-metal seal with fully bonded redundant resilient elastomeric seals that provides a reliable bidirectional and torque resistant anchor in the parent casing.

Designed for use in both new or re-entry wells, the XtremeGrip MLT system serves as a fixed reference point to construct and complete the multilateral junction. The liner hanger also serves as a landing profile that eliminates a dedicated trip to run a separate anchor packer. This helps reduce installation time and CAPEX equipment.

Case Study

Discover how new technology increases completion flexibility to enable multilateral junction construction.

Read Case StudyThe system combines the successful Halliburton technologies of both the XtremeGrip expandable liner hanger and the FlexRite® multilateral system.

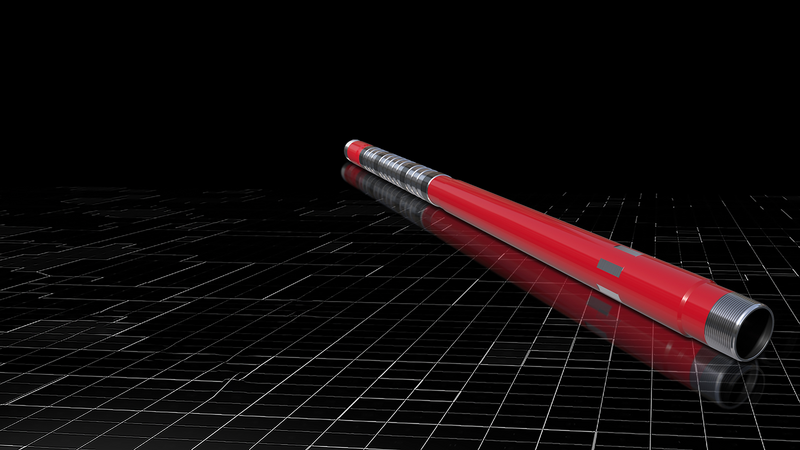

The XtremeGrip liner hanger is set using the standard liner hanger setting tools. Prior to setting the liner hanger, the tool string offers the capability to run a measurement-while-drilling (MWD) tool to place the keyed slot profile at the planned depth and orientation. When set, the liner hanger offers bidirectional load capabilities and provides a gas-tight, liner-top seal.

The multilateral tools are compatible with the XtremeGrip liner hanger. The mating multilateral tools have a keyed latch assembly that self-orients downhole and latches inside the liner hanger. The whipstock assembly is run first to construct the casing exit window. Once the casing exit is milled and the lateral hole is drilled, the whipstock assembly is retrieved and replaced with the completion deflector assembly. The deflector assembly also has a keyed latch assembly that self-orients downhole and latches inside the liner hanger. In both cases, the liner hanger serves as a fixed reference point in the mainbore completion. The junction assembly is installed inside the completion deflector to complete the multilateral junction.

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications

High-performance ELHs with enhanced hang-weight capabilities in elevated temperatures

Field-proven, total system approach to liner installations