Search

Search

Search

Search

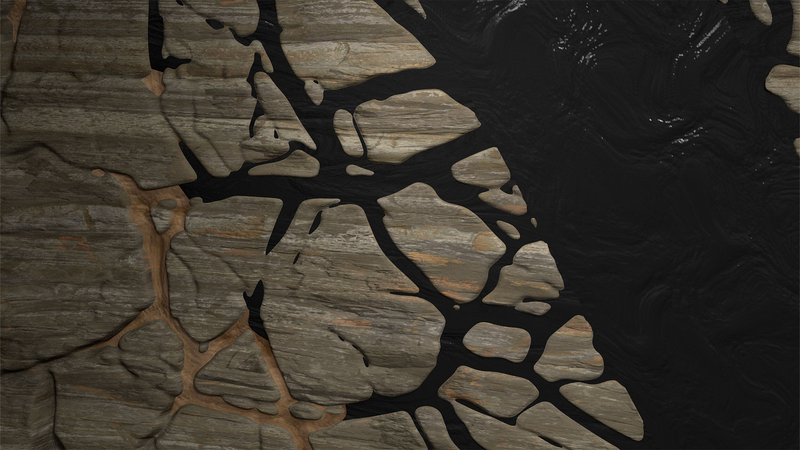

Vaca Muerta stretches across the arid plains of Argentina’s Neuquen Basin, a rugged, remote landscape shaped by wind and dust. Beneath this barren land lies one of the world’s largest shale reserves, rich in hydrocarbons and ripe for unconventional development.

The region’s isolation presents logistical challenges, but it also offers a blank canvas for innovation. Operators built infrastructure from scratch and transformed the basin into a hub of advanced drilling rigs, mobile pressure pumping units, and real-time monitoring stations. This terrain offers a powerful case study in how integrated technologies can improve unconventional resource development. Here, engineers and geoscientists collaborate with operators and apply digital tools, automation systems, and tailored solutions to push the boundaries of shale development.

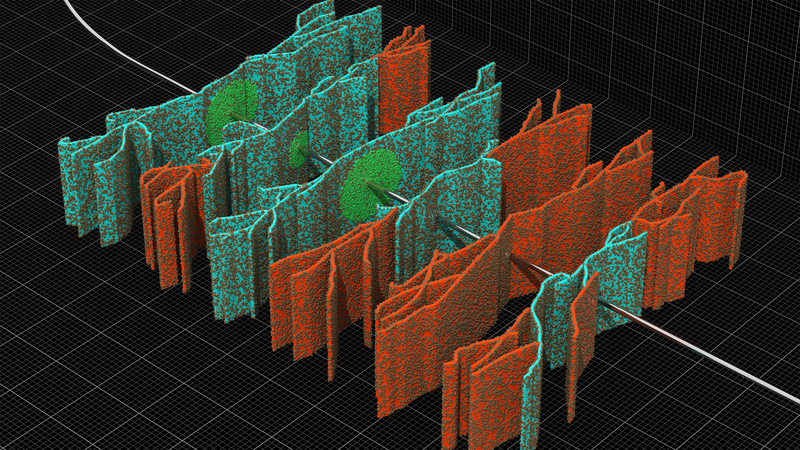

Operators in Argentina recently introduced real-time fracture monitoring with the OCTIV® digital fracturing services and Sensori™ fracture monitoring service. This deployment allowed engineers to monitor 27 fracture stages and detect frac-hit events. With immediate access to downhole data, teams adjusted operations in real time, which improved stage efficiency and reduced delays.

This approach highlights the increased importance of data-driven decision-making in completions. It also emphasizes the value of the integration of monitoring technologies into fracture design and execution.

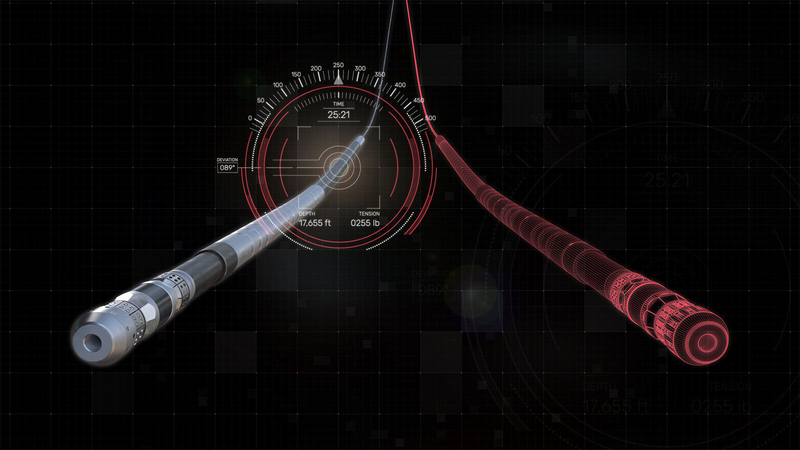

While completions advanced through digital monitoring, drilling operations also reached new milestones. One team drilled 1,747 m in 24 hours by combining several technologies:

LOGIX™ automation and remote operations optimized drilling parameters remotely

iCruise Force™ motor assisted steerable system for well creation provided directional control in complex formations

GTi54HEs drill bit improved depth-of-cut control

An automated pressure management system maintained safe and consistent pressure

In another operation, the team drilled 4,013 m in a single run through curve and lateral sections. These results show how integrated systems can reduce nonproductive time and improve wellbore quality.

Cementing operations in Vaca Muerta often face issues like lost circulation zones and unpredictable subsurface conditions. In one case, engineers mitigated total losses with the use of SentinelCem™ Pro cement system, a customized cementing solution. The team also completed Argentina’s first casing bit run, which improved cement placement and wellbore integrity.

These examples show how cementing practices continue to evolve in response to geological complexity. For engineers and geoscientists, they offer insight into how tailored solutions can improve long-term well performance.

Beyond individual milestones, Argentina OCTIV® auto pumpdown™ service completed more than 1,000 perforating stages in recent months. This achievement reflects a mature and scalable operation, supported by disciplined workflows and reliable technologies.

Vaca Muerta’s recent milestones provide a framework for how unconventional development can evolve when teams apply an integrated approach. Real-time data, automation, and tailored engineering solutions create a foundation to achieve consistency, safety, and scale. The collaboration across disciplines, including geoscience, engineering, and operations, unlocked complex reservoirs and delivered results. The successes at Vaca Muerta also show how innovation sometimes means the combination of mature tools in smarter ways.

Explore how intelligent fracturing and integrated services support unconventional development in Argentina.

We are integrating insights, automation, and intelligence to improve the performance and efficiency of fracture operations.

Increase the consistency and performance of well construction operations by integrating subsurface automation, digital twins, and remote operations.

Swelling solution designed for barrier dependability and helps provide increased cement sheath elasticity.

Expand drilling capabilities to optimize drilling performance and maximize asset value.

SentinelCem Pro is a unique, single-sack lightweight lost-circulation solution that enables proactive storage at the rig site to cure severe to total losses.

OCTIV Auto Pumpdown service controls fluid pumps and a wireline unit as a single, fully automated, closed-loop system to maximize plug and perforating performance.