Search

Search

Search

Search

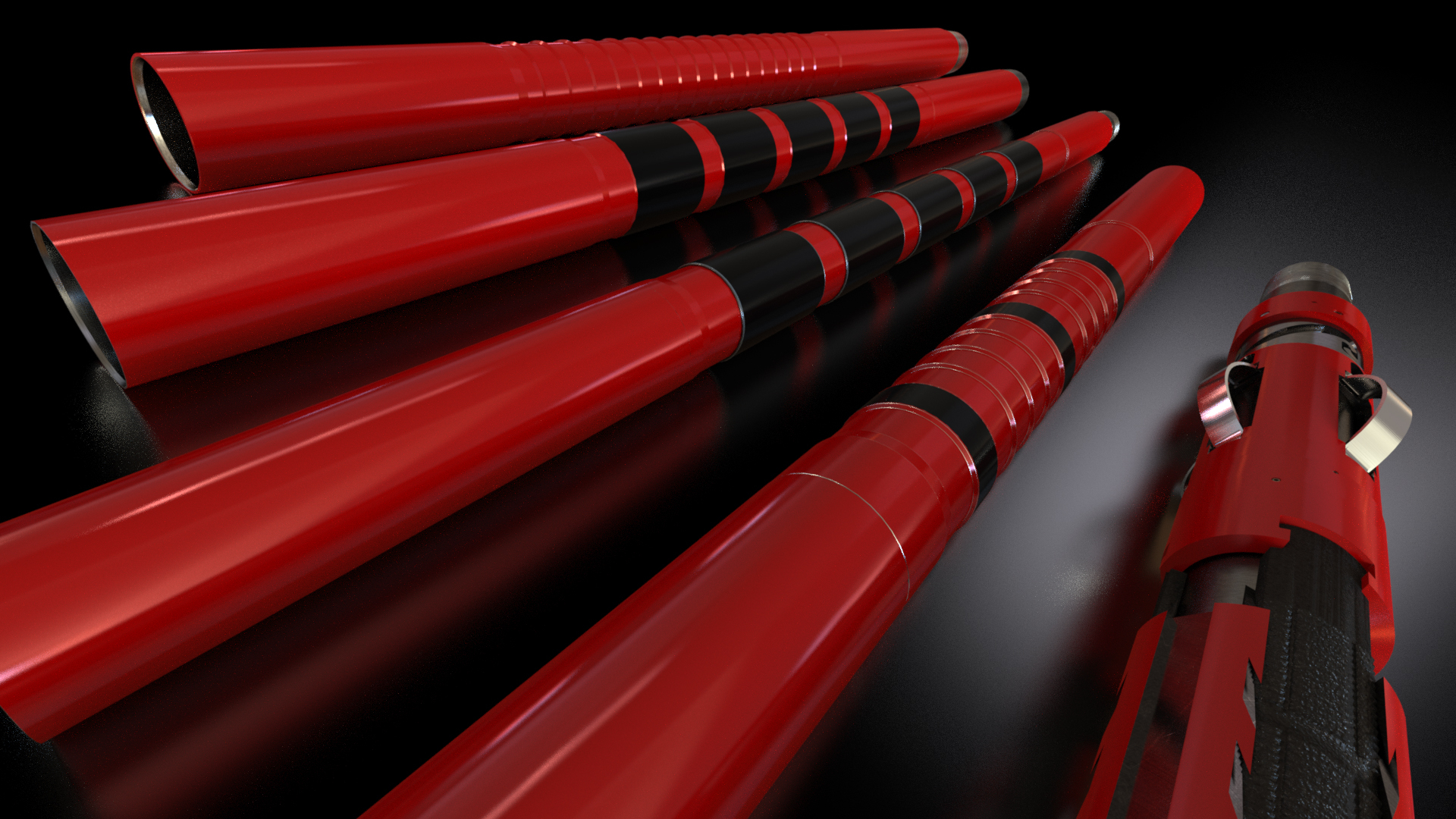

Expandable and conventional options for land, unconventional, ultra-deep water and geothermal applications.

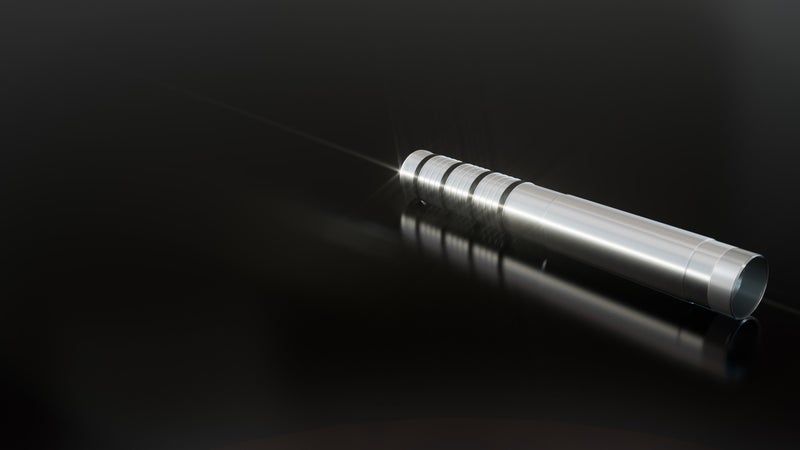

Talk to an expertWith over 25 years of global experience, our comprehensive liner hanger portfolio features expandable, mechanical- and hydraulic-set systems with options for ultra-high hanging capacity, high bypass, and rotation while cementing.

Halliburton liner hanger systems are ISO 14310 V0-qualified and can be deployed in all types of environments – medium, extreme high-pressure/high-temperature (HP/HT), and ultrahigh temperatures up to 650° F (343° C).

Latest Case Study

XtremeGrip® ELH LECD system helps operator reach TD and cement liner in unstable borehole offshore Western Australia

Read Case Study

Field-proven, total system approach to liner installations

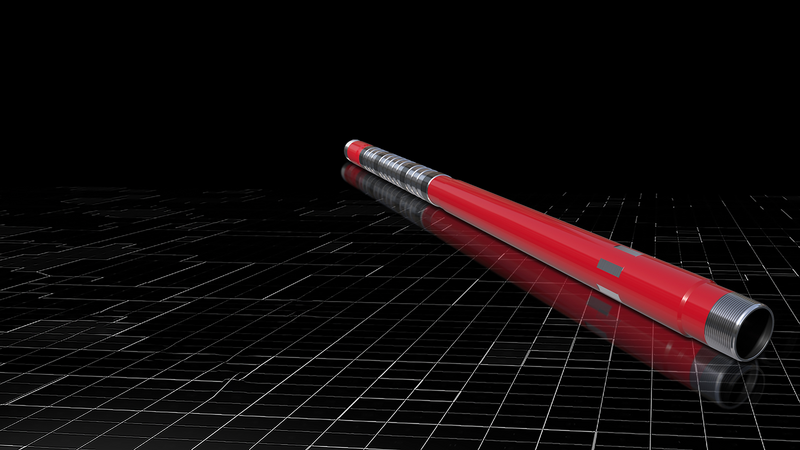

Improve the reliability of subsea installations with high-performance liner hangers

High-performance ELHs with enhanced hang-weight capabilities in elevated temperatures

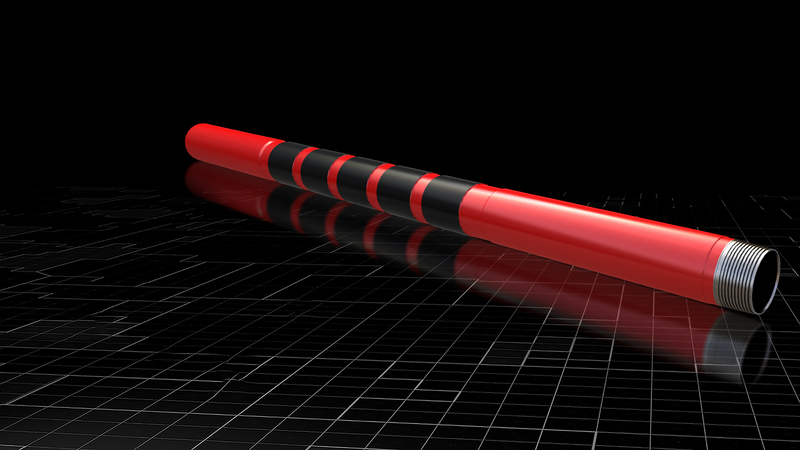

Offer system configurations for cemented and non-cemented land solution applications

Halliburton liner hanger systems allow the liner to be suspended in the previous casing string by providing reliable sealing and a bi-directional anchor capability. A seal at the top of the liner hanger prevents the transfer of fluid or pressure from either direction. Our liner hanger systems enable operators to reduce material costs and gain greater operational flexibility without compromising well integrity.

37 XtremeGrip® liner hangers installed across 7 Stampede wells with zero nonproductive time issues.

Read Article