Search

Search

Search

Search

The Halliburton approach to fracturing maximizes surface and subsurface efficiency to optimize the value of your capital investment

talk to an expertOperators in unconventional reservoirs and high-pressure environments require precision and speed to lower costs per well and improve production consistency. Our hydraulic fracturing services combine reliable surface operations with scalable subsurface solutions that help reduce nonproductive time and support predictable execution. Customers gain dependable equipment performance that helps ensure real-time fracture control, fuel alternatives, and comprehensive logistics support.

Help maximize recovery and minimize risk with solutions tailored to your reservoir and operational objectives. Achieve consistent results across any environment, from vertical conventional reservoir wells to multi-well pads in tight shale and from land to offshore projects. With technical expertise, advanced technology, and global resources, we deliver safer, more efficient completions that help reduce expenses and optimize performance.

To meet unique demands, operators need to define surface and subsurface outcomes and achieve them with confidence. The ZEUS IQ™ intelligent fracturing platform, powered by OCTIV® auto frac service and Sensori™ fracture monitoring service, delivers autonomous frac execution, real-time reservoir feedback, and actionable insights. These solutions help operators reduce cycle time, limit variability between stages, and protect asset performance from the office or the field for consistent, high-quality results worldwide.

The industry’s first closed-loop system combines operator asset knowledge with automated controls to help support fracture execution and placement without traditional human intervention. This digital solution deploys intelligence at the wellsite for fleets to execute autonomously based on defined criteria. This approach helps identify actions that improve asset performance and maintain stability.

Continuous data supports faster decisions with real-time visibility into operations. Tools like OCTIV® connect portal give customers the ability to monitor activity, identify trends, and apply analytics instantly during pumping. This constant flow of information helps reduce cycle times and improve overall efficiency.

Time is critical. Simul-frac operations help reduce days on location and accelerate time to first oil by stimulating more stages across multiple wells with a single fleet. This advanced approach delivers peak performance through endurance and horsepower, reduces cycle time, increases lateral footage, and decreases costs. Operators move from plan to production faster, improve asset deployment, and increase operational safety and consistency across the pad.

We are integrating insights, automation, and intelligence to improve the performance and efficiency of fracture operations.

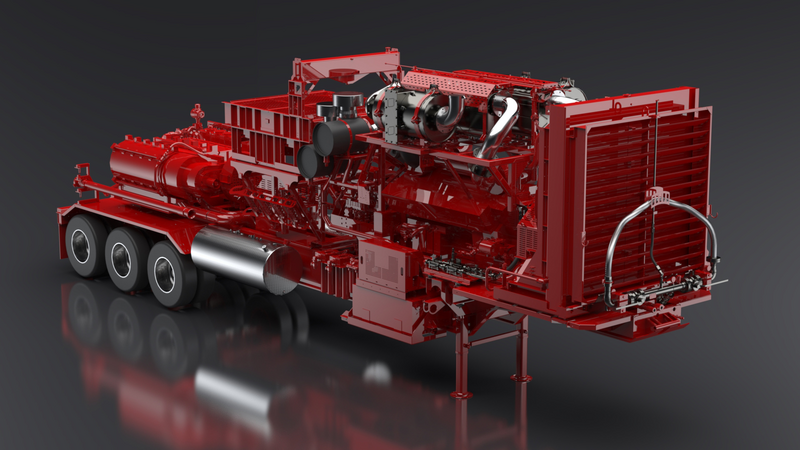

From the pump to the wireline unit, our fully integrated ZEUS® fracturing services offer an all-electric frac site that maximizes efficiency gains, reduces fuel costs and lowers overall emissions.

Our simultaneous fracturing services optimize hydraulic fracturing with real-time data transfer and AI tools, enhancing well productivity and efficiency

Our history of fracturing achievement is due to continuous technology innovation, proven best practices and global experience.

Halliburton dual fuel Tier 4 systems offer a lower emissions profile and reduced costs compared to dual fuel Tier 2 engines.