Search

Search

Search

Search

New technology increases completion flexibility to enable multilateral junction construction

Download PDFMature Fields

Extend production life of a mature well with new XtremeGrip MLT anchor system

Offshore Stavanger

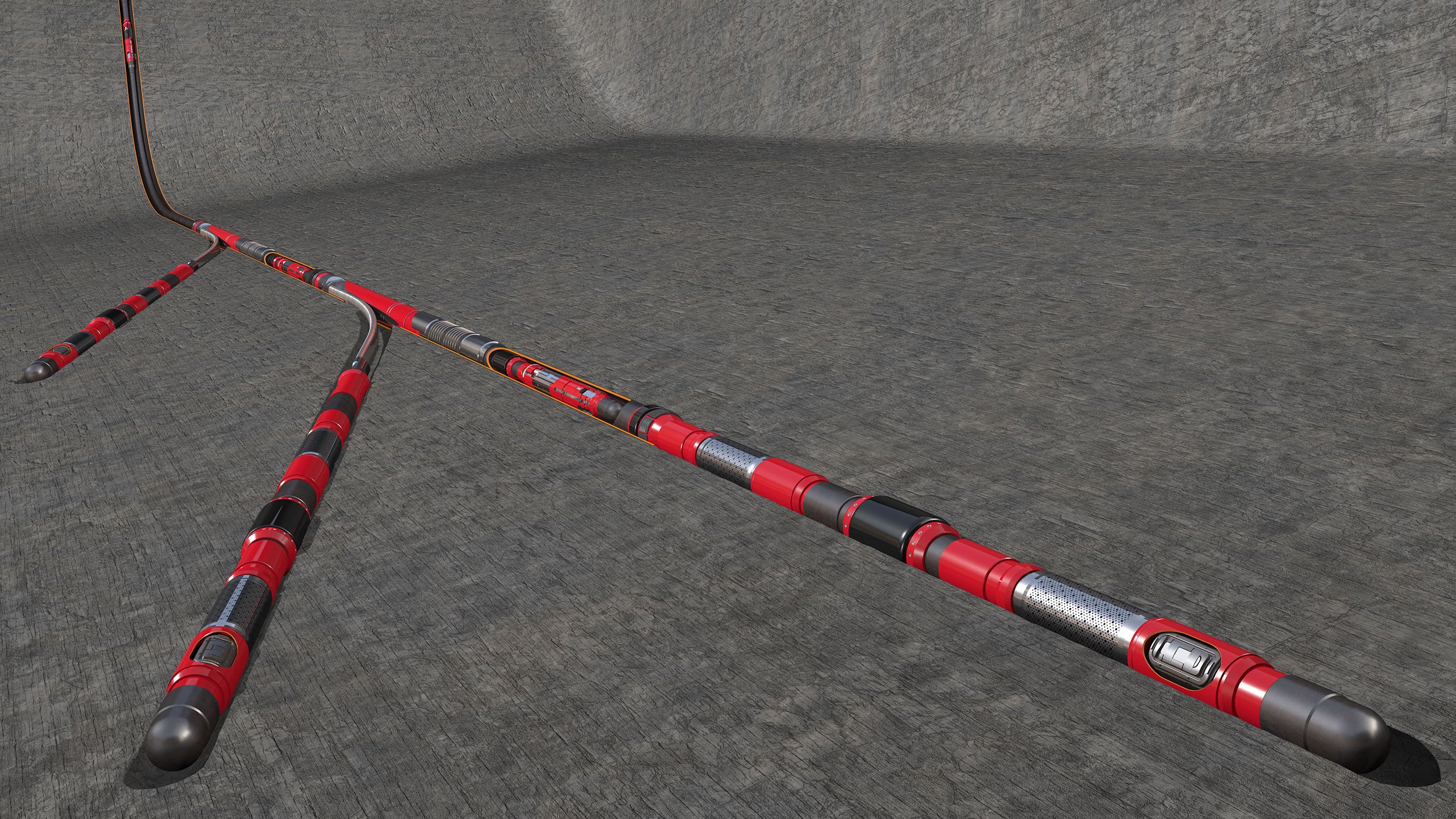

A well in offshore Norway was originally completed in 2004 as the first-ever quad lateral installation in Norway. This well combined commingled production, using standard Halliburton FlexRite junctions, which was considered pioneering technology at the time. In 2014, after 10 years of initial production, the well was plugged and redrilled as a new quad lateral well – this time, using multibranch inflow control (MIC) technology to allow individual control of all four laterals, and to further extend the life of the well. In 2019, as the well was possibly reaching the end of its natural lifetime, it was once again redrilled as a dual lateral, using the Halliburton ReFlexRite completion system with a 9 5/8-inch intelligent completion interface (ICI) system – and its new XtremeGrip MLT anchoring technology.

This offshore well featured multiple challenges on different levels. The customer’s focus was on extending production recovery. It was necessary to drill a new lateral branch in order to enable new production from this mature wellbore. To establish a foundation for the re-entry capabilities of this branch, an anchor was required to provide a broad scope to position a junction at the desired depth in order to enable lateral construction.

Previously used anchor systems had limited tensile, torque, and inside diameter (ID) capabilities that restricted or limited junction construction. To avoid these obstacles, Halliburton proposed and completed the first installation of its XtremeGrip MLT anchor system in Norway for this well, which helped the operator overcome the challenges of extending the production life of this mature well. This system was developed to provide increased completion flexibility through more tensile, torque, and ID capabilities than had been offered through the traditional anchor systems.

The increased tensile rating of the XtremeGrip MLT anchor system allows the capability to deploy screens, slotted liners, or cemented liners directly below the XtremeGrip MLT anchor, which eliminates the requirement for a separate trip with a liner deployment. The system’s increased torque rating (up to 20,000 ft-lb) is three times higher than that of traditional systems. Its larger ID makes the XtremeGrip MLT anchor system compatible with field-proven MIC systems. This system also allows orientation of the anchor to the desired exit point prior to setting the anchor with measurement-while-drilling (MWD) tools. The XtremeGrip MLT anchor system was designed to provide additional reliability for anchor systems, and to offer a broader scope for positioning and orienting the anchor.

installation of XtremeGrip MLT anchor system in Norway

With the successful deployment of the reliable XtremeGrip MLT system, the operator saved trip time by deploying screens below the anchor. The XtremeGrip MLT system also saved the operator from having to purchase additional equipment for a separate screen deployment. Additionally, the system allowed for larger IDs, enabling the use of an intelligent completion interface (ICI), which provided independent flow control for the main bore and lateral production. The XtremeGrip MLT system ultimately enabled the operator to save rig time and costs, and to successfully extend the production life of this mature well.

Expandable liner hangers

The XtremeGrip™ MLT expandable liner hanger (ELH) system offers an integral multilateral self-orienting profile to allow the hanger to provide positive depth and orientation control in multilateral wells for offshore and onshore applications.

Download Data Sheet