Search

Search

Search

Search

Operators face constant pressure to hit production targets and improve recovery while they manage subsurface uncertainty. Traditional earth modeling tools and data acquisition methods often cannot keep pace with the complexity of modern reservoirs. As data volumes grow from logging-while-drilling and wireline runs, core samples, and seismic surveys, operators need technologies that can analyze and model the subsurface in real-time.

Tools powered by artificial intelligence (AI), machine learning, adaptive algorithms, and digital rock analysis help tackle these subsurface exploration challenges. These technologies deliver sharper, faster insights that improve decision-making and help reduce risk. Operators can unlock more value from assets, improve recovery, and even support geothermal power generation and lithium extraction projects.

Here are three ways digital technology outperforms traditional methods in subsurface characterization.

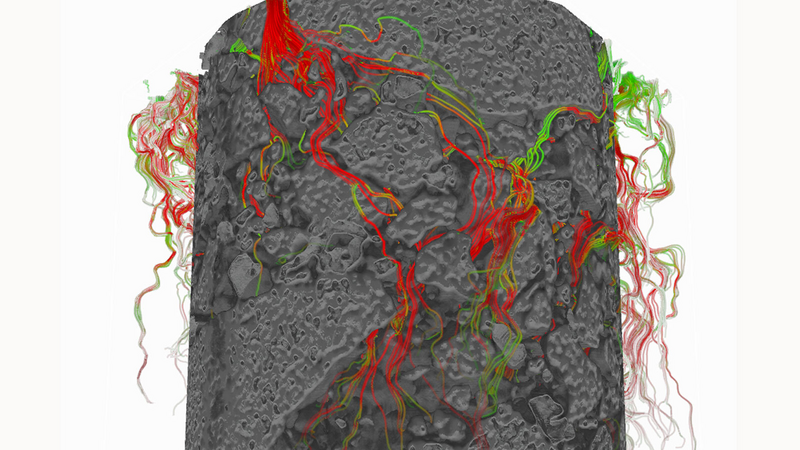

Modern data integration frameworks and AI algorithms process massive datasets from seismic measurements, well logs, and core samples in real time. This gives operators a clearer, more current view of the subsurface. This also helps them reduce uncertainty and make faster, more confident decisions. Machine learning models spot patterns and correlations that traditional methods often miss. This can lead to more accurate predictions of rock and fluid properties.

Today’s subsurface evaluation technology includes high-speed telemetry and automated surface well testing workflows. High-speed telemetry instantly sends detailed downhole data to the surface. When combined with forward-looking geological imaging, it gives drilling teams real-time visibility into rock formations, fluid boundaries, and potential hazards so they can adjust well paths instantaneously. These insights also power automated geosteering, which uses real-time formation data to create predictive models that accurately guide well placement with minimal intervention. Surface automation platforms can streamline well testing, cut down on human error, and boost efficiency.

Advanced earth modeling provides a digital blueprint of what lies beneath the earth’s surface with unprecedented clarity. These models use historical and real-time data to predict subsurface properties and behavior, pinpoint resources, and guide drilling decisions.

Integrated platforms combine seismic processing, geological interpretation, and geophysical analysis to build high-resolution models. These tools reveal the structure and composition of subsurface layers and fluids with precision. Operators can define reservoir boundaries more accurately, avoid unproductive zones, and make smarter decisions to optimize assets.

AI and machine learning help operators spot risks early, optimize drilling, and improve safety. These tools improve data integration, speed up interpretation, and boost predictive accuracy. The conversion of raw data into actionable insights helps teams make better decisions faster.

Machine learning workflows detect anomalies to help quantify risks and improve scenario modeling. Explainable AI models estimate hydrocarbon potential and fluid characteristics to create a clearer picture of what to expect when drilling begins. All this can add up to more accurate earth models, increased reliability, and lowered exploration and development risk.

To stay competitive, operators must move beyond outdated subsurface characterization methods. Digital technologies such as AI, machine learning, and advanced modeling facilitate faster, smarter decisions across every stage of a well’s lifecycle. They reduce uncertainty, improve recovery, and unlock new opportunities in oil, gas, geothermal, underground carbon storage, and lithium extraction.

Explore how Halliburton helps operators dive deeper with digital solutions that deliver accurate, efficient, and confident subsurface characterization.

Increase the consistency and performance of well construction operations by integrating subsurface automation, digital twins, and remote operations.

Fully digital and web-enabled to monitor and control drilling and logging operations from anywhere.

In-depth geological insights to identify new opportunities and understand critical risks.

Control, measure, and analyze surface well testing through automated workflows.

Reduce uncertainty and turnaround time for estimations of hydrocarbons in place using fast capillary pressure and resistivity index relationship services

Combines innovative technology and tightly integrated, end-to-end suite of cross-domain workflows to increase subsurface understanding, reduce uncertainty around today’s most complex reservoirs and tackle future energy challenges.