Search

Search

Search

Search

High-performance liner hanger solves deepwater well challenges in elevated temperature

Download PDFDeep Water

Installation of a liner hanger in complex deepwater well

GOA

XtremeGrip liner hanger with extrusion rings provides:

An operator in the Gulf of Mexico had just finished drilling the final section of their most recent deepwater well. The 8 1/2-in. x 9 7/8-in. openhole section was side-tracked through a 10 1/8-in. casing window at a depth of 24,210 ft and reached approximately 28,000 ft total depth. The 10 1/8-in. parent casing was set 34 degrees inclination, and the openhole section reached a maximum deviation of 59 degrees at total depth. A liner hanger was required to reliably run approximately 4,000 ft of 7 3/4-in. production liner to depth, cement the liner hole annulus to isolate the production sand, and hang the liner with a liner-top anchor/seal package – a feat that had not been performed without issue using conventional equipment.

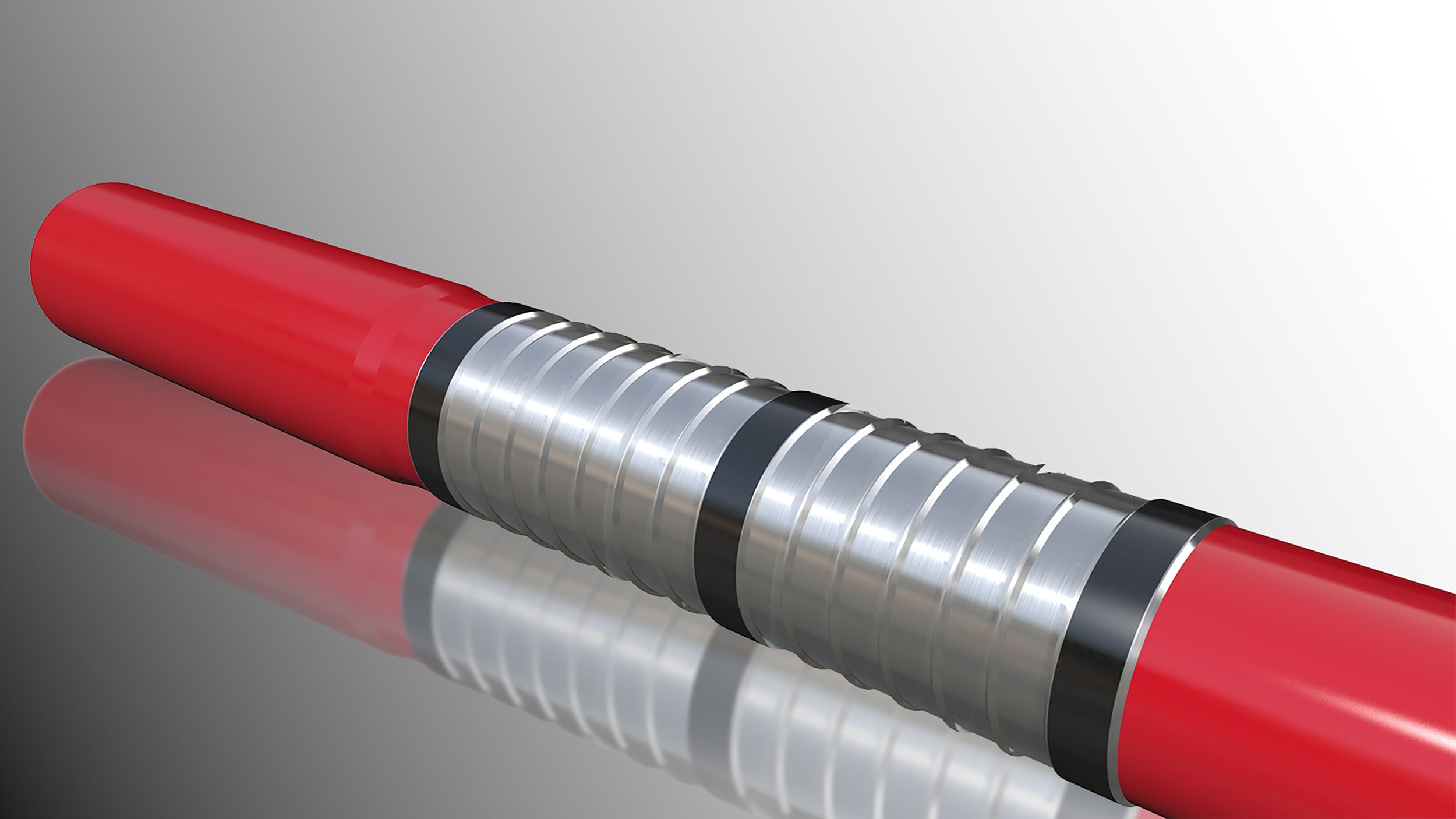

While the 81 lb/ft heavy wall parent casing presented a challenge in pre-job models for the traditional VersaFlex® liner hanger system, the XtremeGrip system was up for the challenge. What makes the expandable section of this hanger unique is a series of extrusion rings that replace most of the sealing and anchoring elastomers. These rings are similar to the machined ribs found normally on either side of an elastomer, and when expanded, create a metal-to-metal contact that provides high performance at elevated temperatures. With the XtremeGrip system design, thick wall casing is no longer a challenge. This marks the first installation of the XtremeGrip system in the Gulf of Mexico.

maximum deviation

ft of casing run

NPT

Over 4,000 feet of casing was run to bottom of the deviated well, which reached a maximum deviation of 59 degrees. Halliburton performed the cement job, isolated the formation, and set the hanger. The hanger expanded under pressure very close to what our modeling engineers predicted. The job was a success with ZERO NPT and the customer has placed more orders for the XtremeGrip system for their future GoM jobs.