Search

Search

Search

Search

Precise bit designs and Juggernaut® X cutters help maximize directional performance

Download PDFMature Fields

Horizontal geosteering in conglomerate and basement reservoir

Norway

In the Norwegian Continental Shelf, drilling through conglomerate and basement formations, such as granite and granodiorite, presents challenges to the rate of penetration (ROP) and the durability of the drill bit cutting structure. To address these challenges, an operator collaborated with Halliburton to implement a novel bit design and drilling strategy. The goal was to drill long horizontal sections in three runs or fewer, with an average of 1,000 m per bit run. The operator also aimed to maintain high ROP, minimize tool failures, and achieve cost-effective project execution.

The operator encountered significant challenges while drilling through the conglomerate and basement reservoir. They required five separate bit runs to cover a distance of 2,903 m, with individual runs ranging from 149 m to 1,219 m. The bit designs at the time, seven-blade, dual-row configurations, failed to deliver consistent performance across the varying lithologies. As a result, the ROP fluctuated between 11 m/hr and 24 m/hr, which reduced drilling efficiency and increased both operational time and cost.

To address these issues, the operator asked Halliburton to develop a more efficient solution to achieve longer runs and higher ROP in three runs or less.

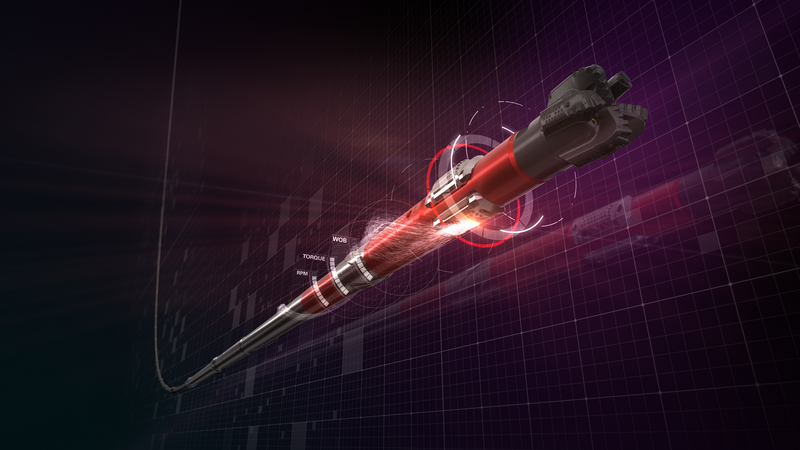

Halliburton introduced a performance-driven bit design strategy that prioritized drilling efficiency over conventional durability-focused methods. The 8 ½-in. Hedron® drill bit was engineered with a five-blade, dual-row configuration to reduce energy requirements, improve ROP and cutting evacuation, and allow more flow to cool the PDC cutters. This approach aimed to minimize well time and maximize drilling performance.

Razor™ Juggernaut® X cutters were chosen for their unique shape, which balances durability and cutting efficiency. This design enabled greater depth of cut, improved stability, and reduced stress on the BHA. It helped minimize the risk of tool failure and maximized drilling performance in the basement formation.

Meters drilled in one run to total depth

Days of offshore rig time saved

m/hr ROP

Total depth was reached in 13 days, ahead of the 20.5 days plan, and with two fewer bit/BHA trips than planned. This performance saved 7.5 days of offshore rig time and reduced operational costs. The achievement demonstrates the feasibility of efficient basement drilling and creates new opportunities for future development in the region.

The 8½-in. Hedron® drill bit drilled 3,296 m of chalk, conglomerate, and basement rock in a single run to total depth with an ROP of 23.6 m/hr. This run marked the longest basement section ever drilled in the Norwegian Continental Shelf. The wellbore inclination increased from 75° to 90° and landed horizontally using the 6 ¾-in. iCruise X® intelligent rotary steerable system.

To maintain precise geosteering within the reservoir, the team deployed a full suite of formation evaluation services: EarthStar® very deep resistivity service, LithoStar® integrated neutron porosity and density service, and MRIL® magnetic resonance imaging service. The BHA also incorporated BaseStar® service, integrated wellbore placement, stability, and drilling optimization service, along with GeoTap® formation pressure testing service. These tools enabled detailed reservoir characterization and supported informed decision-making.

Juggernaut X PDC cutters increase rate of penetration (ROP) and reduce well construction time. They offer superior durability and efficiency.

The Hedron® platform of fixed cutter drill bits combines state-of-the-art technology with an industry-leading customization process.

Automation-enabled platform designed specifically for longer well applications in harsh environments.