Search

Search

Search

Search

Electro-mechanical selectable shifter to mechanically override barrier isolation valves, ICVs, or completion devices that require manipulation

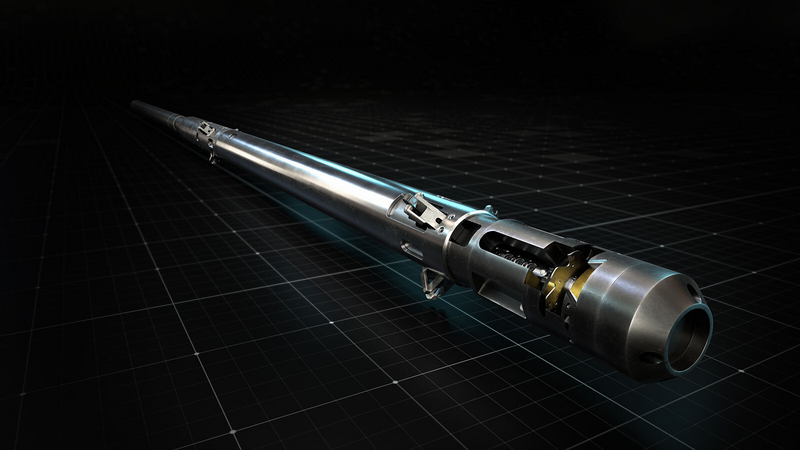

Talk to an expertClearShift™ service delivers precision electro-mechanical actuation for barrier valves, internal control valves (ICVs), and sliding sleeves in high-pressure, high-temperature wells. Designed for intelligent completions and contingency override scenarios, ClearShift service provides a non-explosive alternative to traditional shifting tools.

ClearShift service features a compact 2.25-in. run-in-hole (RIH) outer diameter, enabling passage through barrier isolation valves and compatibility with multi-ICV configurations. The tool’s high-expansion shifter lands securely in FS2 contingency profiles, ensuring reliable valve manipulation even in stuck or failed sleeve conditions.

Minimum ID restriction

Tool weight

Maximum temperature

Tool outside diameter

The anchor section includes three large 3 × 1-in. pads, delivering over 50,000 lbf of radial force while minimizing pipe impressions. Two anchor sizes accommodate pipe diameters from 3.5 to 7.0 in., supporting a wide range of well architectures. This design ensures secure anchoring without compromising pipe integrity.

ClearShift service actuator delivers 28,000 lbf of force with a 2.2-in. stroke length and 0.25-in. accuracy. The electrical feedthrough design supports communication to lower tools, enabling integrated operations with ClearTrac® tractor service, ClearCut® cutters, and ClearMill® milling tools. This bidirectional capability allows multiple shifting operations in a single wireline run, improving operational efficiency.

Compatible with mono, hepta, and coated cable deployments, including tractor-assisted wireline runs, ClearShift service operates in environments up to 350°F and 20,000 psi. A 30,000-psi option is available upon request, making it suitable for extreme downhole conditions.

ClearShift eliminates the need for explosive chemicals in well interventions

The ClearTrac tractor service is the most advanced wireline conveyance technology on the market for highly deviated or horizontal wells.

ClearCut powered mechanical cutting tools perform precise, machine-shop quality, radial pipe cuts, regardless of depth and pipe compression.

Part of the Clear™ mechanical family offer, an electro-mechanical solution for stuck ball valves in downhole completion that cannot be mechanically overridden

ClearShift™ service employs advanced electro-mechanical technology to handle contingency override scenarios in downhole completion devices

The ClearBail™ bailer service is a versatile, dual-function device designed to clear blockages in downhole completion hardware, such as barrier isolation valves

ClearShift supports well intervention and diagnostic workflows

Addressing the toughest issues in well intervention, Halliburton offers services to extend well life, improve performance, and limit downtimes.