Search

Search

Search

Search

A solution to address stuck ball valves that cannot be mechanically shifted

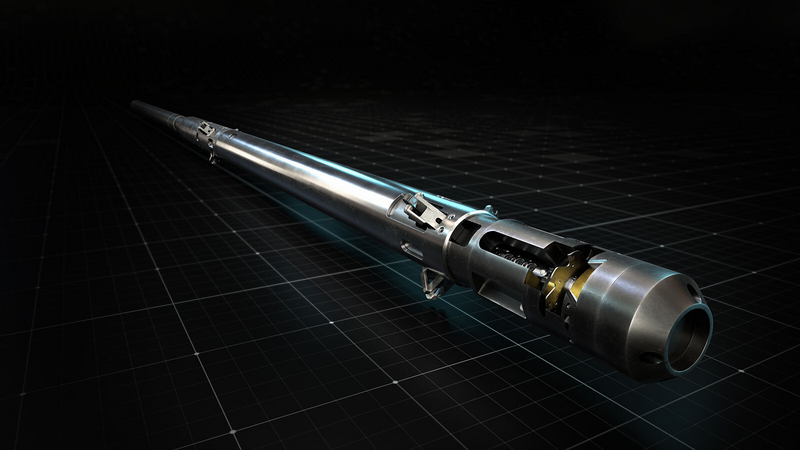

Talk to an expertClearMill electro-mechanical miller is a high-performance wireline tool engineered to remove stuck downhole components in high-pressure, high-temperature wells. Designed for precision and safety, ClearMill miller enables well intervention teams to mill through plugs, valves, locks, and other completion devices, without the risks associated with explosive cutters.

This non-explosive solution integrates three core modules: anchor, actuator, and rotary unit. With a compact 2.25-in. run-in-hole diameter, the tool navigates barrier isolation valves and tight well geometries. The actuator applies precise weight-on-bit using a high-force electric feedthrough, while the rotary module delivers up to 150 lb-ft of torque at 400 RPM. The anchor stabilizes the tool during high-torque operations, minimizing pipe impression and eliminating slip under load.

ClearMill miller is compatible with ClearTrac™ e-line tractors, ClearCut™ cutters, and ClearShift™ shifters, supporting rigless and coiled tubing workflows. Whether deployed in plug and abandonment (P&A), recompletion, or sidetracking operations, ClearMill miller provides the flexibility and reliability needed to restore well access and optimize production.

In well abandonment and intervention scenarios, safety and compliance are critical. ClearMill miller eliminates the need for explosives, reducing operational risk and simplifying logistics. Its electro-mechanical design allows for controlled milling in sensitive environments, making it ideal for P&A engineers, well services supervisors, and subsurface specialists seeking a safer alternative to traditional casing millers.

ClearMill miller removes stuck ball valves, flapper valves, plugs, locks, nipple profiles, and ball seats—even in challenging materials and complex well conditions. Its customizable mill-bit designs match the chemical composition of the target metal, ensuring efficient material removal and minimal damage to surrounding infrastructure.

The tool’s sensor sub provides real-time downhole feedback, including pressure, temperature, tension, inclination, and vibration data. This allows engineers to monitor milling performance and make informed decisions during live operations.

Minimum ID restriction

Tool weight

Maximum temperature

Tool outside diameter

ClearMill miller supports deployment via hepta, mono, and coated-mono cables and is fully compatible with Halliburton’s tractor services. Its dual anchor sizes accommodate pipe diameters up to 7 in., while the actuator’s 12.2-in. stroke length ensures consistent force application across varied intervention scenarios.

With a maximum operating temperature of 350°F and a pressure rating of 20,000 psi, plus a 30,000 psi option available, ClearMill miller is built for the most demanding well environments.

From initial completions to late-life interventions, ClearMill miller supports the full lifecycle of well operations. Production engineers rely on it for tubing recovery, while drilling engineers benefit from its precision during sidetracking and stuck pipe removal. Its adaptability makes it a valuable asset for operations engineers coordinating complex logistics and service deployments.

Halliburton cased hole logging tools give operators the measurements to optimize reservoir performance and evaluate well integrity.

The ClearTrac tractor service is the most advanced wireline conveyance technology on the market for highly deviated or horizontal wells.

ClearCut powered mechanical cutting tools perform precise, machine-shop quality, radial pipe cuts, regardless of depth and pipe compression.