Search

Search

Search

Search

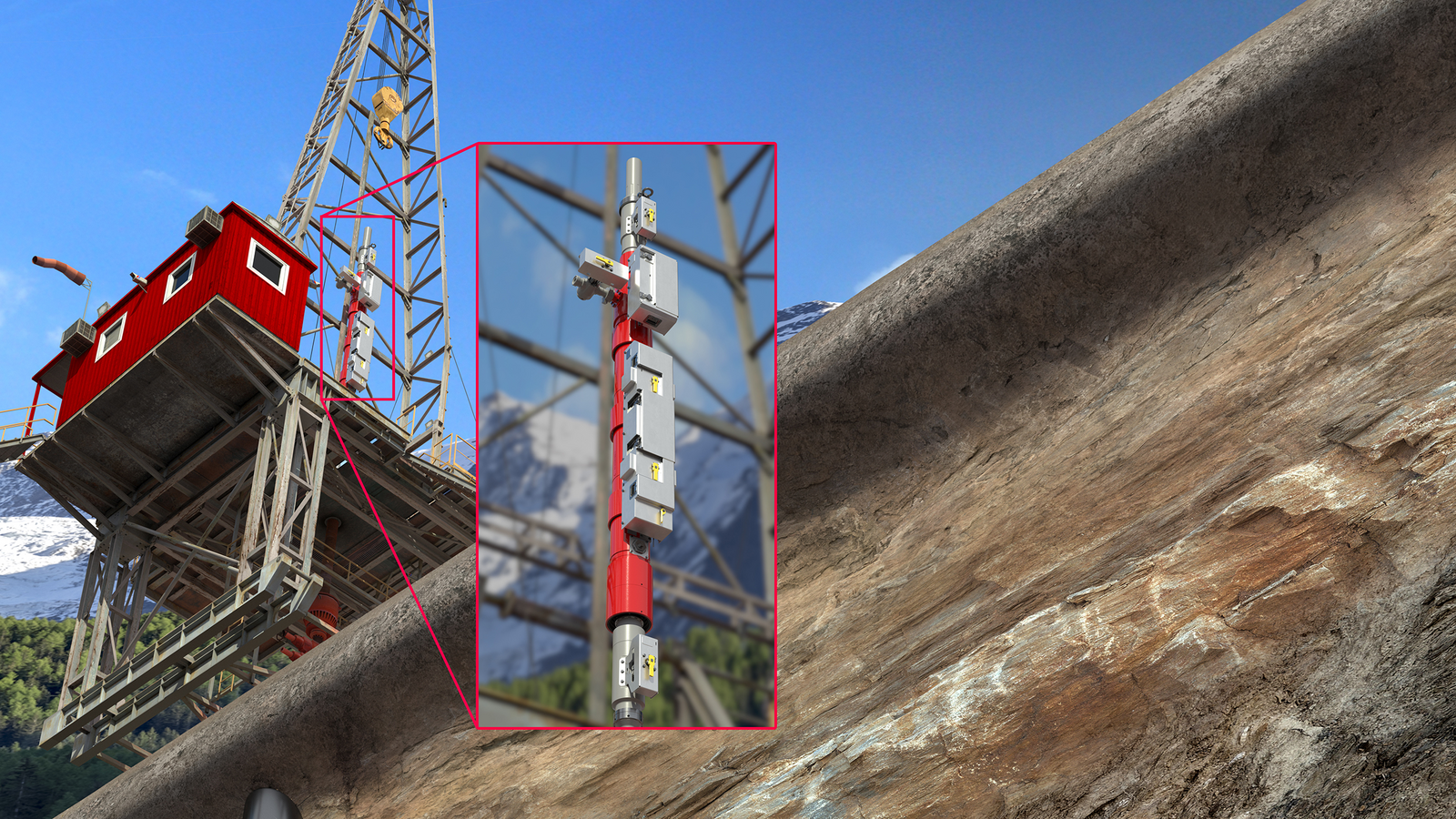

Enabling rotation and reciprocation to improve cement coverage and reduce communication between frac stages to maximize asset value

Talk to an expertCement jobs in unconventional land operations with extended lateral sections often face significant challenges toward properly placing cement barriers with minimal channeling. The Commander™ full bore cement head enables rotation and reciprocation to deliver effective cement coverage, while reducing communication between frac stages to maximize asset value.

UNCONVENTIONAL RESERVOIRS

Today’s land-based operations often utilize wellbores with significantly longer lateral sections to maximize production at a lower cost per BOE. This well design brings challenges to landing casing at planned depth and creating dependable barriers. The Commander full bore cement head is designed specifically to help improve barrier coverage and effectiveness.

COMMANDER FULL BORE CEMENT HEAD

Improve cement coverage while reducing communication between frac stages and maximizing asset value.

The Commander full bore cement head incorporates a number of operational efficiency features to help reduce non-productive time (NPT) and deliver effective barriers at a faster pace. Quick rig-up can be accomplished in as few as 30 minutes on average, while on-site plug loading provides rig site verification. Fast rig-to-rig transitions are realized with minimal downtime, as the Commander full bore cement head can complete up to five runs before redress is required.

Advanced safety features can help reduce risk to on-site personnel. Wireless capability helps prevent personnel from being hoisted, loading plugs, and hand-torquing on active rigs. Embedded wireless logic prohibits plugs from being launched out of sequence, and external tattletale indicators offer easy visual verification when plugs have successfully launched. On-site plug loading offers operators real-time assurance without relying on alternative offsite verification, and if needed, plugs can be launched manually as a contingency.

The Commander full bore cement head is specifically designed to improve cement head reliability, increase efficiency, and help deliver the best possible cement barrier. Multiple industry studies have shown that rotation during cementing can greatly improve barrier coverage and help reduce channeling. With rotation and reciprocation capabilities delivering enhanced cement bonds, the Commander full bore cement head can help maximize barrier coverage in challenging unconventional land operations.