Search

Search

Search

Search

CleanWell® mechanical wellbore cleaning tools placed above an XtremeGrip® ELH system enable efficient three-well campaign in Norway

Download PDFMature Fields

Minimize rig time in non-cemented liner application

Norway

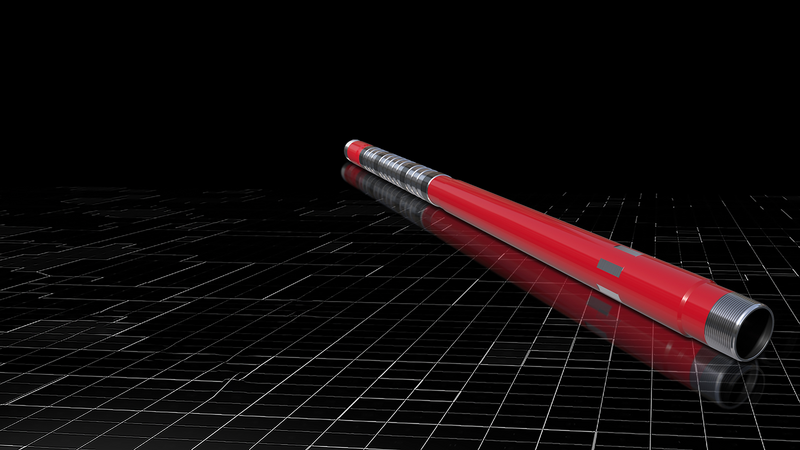

Complex deployment string comprised of:

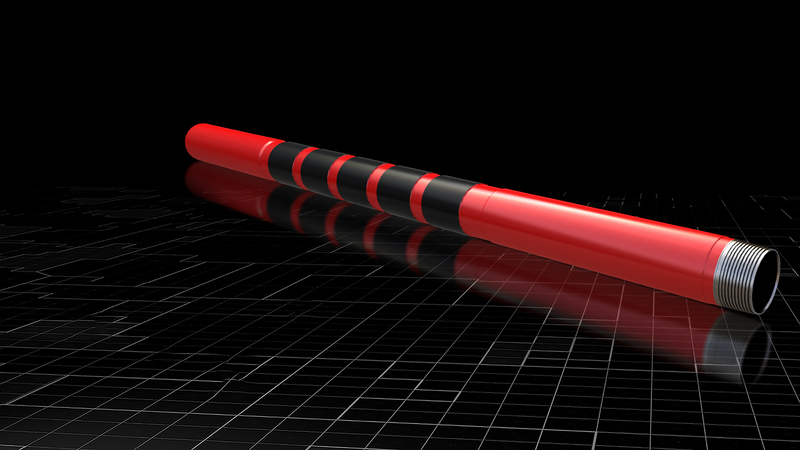

In a three-well campaign offshore Norway, an operator sought to reduce rig time by combining wellbore cleanup and lower completion installation into a single run. Halliburton deployed CleanWell® mechanical wellbore cleaning tools above the XtremeGrip® expandable liner hanger (ELH) system to meet this objective. Simulations revealed that high flow rates alone would not sufficiently clean the wellbore for upper completion installation. The operator required a solution that allowed for the rotation of the deployment string at 60 to 80 rev/min after releasing the VersaFlex® ELH running tool, without risking tool damage or operational delays.

The lower completion included SSD and ICD screens, a high-pressure float valve, swell packers, FS2 valve, and the XtremeGrip ELH. The well’s horizontal section featured a highly deviated angle at the top of liner (TOL), adding complexity to the operation.

Upon retrieval of the VersaFlex ELH running tool from the liner hanger assembly, multiple collet fingers are exposed to the well. Rotation of the running tool can potentially cause collets to break off, which requires subsequent fishing runs to retrieve missing or broken running tool parts.

The deviation at the TOL—ranging from 75 to 83°—meant the running tool could contact the parent casing post-release, increasing the likelihood of damage. The operator needed a documented, repeatable solution that minimized rig time and avoided nonproductive time (NPT).

Halliburton recommended a complex deployment string to help mitigate risks and enable simultaneous wellbore cleanup and completion installation. Key components included:

The drill pipe swivel was run in-hole (RIH) in the locked position and activated at 84 bar (1218 psi) during ELH expansion. A confirmation overpull test validated the expansion, followed by a rotational test with 20 mtf (44,092 lbf) of tension to confirm swivel activation. The running tool was then released via compression and retrieved above the TOL. The circulating valve was activated, and rotation commenced for wellbore cleanup.

Wells completed with offered configuration

Runs completed with configuration in Norway

Clean wellbore with reduced rig time

NPT or SQ issues

All three wells were completed using the integrated tool configuration. While fluid losses occurred in the first two wells, they were minimized, and operations continued without interruption. The third well experienced no losses. All operations were completed within the expected timeframe, with no service quality events or NPT. The documented process demonstrated the viability of running CleanWell® tools above an ELH system in non-cemented liner applications, delivering a cleaner wellbore and reduced rig time.

High-performance ELHs with enhanced hang-weight capabilities in elevated temperatures

Field-proven, total system approach to liner installations

Complete portfolio of filtration services, wellbore cleanup fluids, mechanical wellbore cleaning tools, and software modeling