Search

Search

Search

Search

Successful integration with third-party wired drill pipe system enables data-driven drilling without downhole batteries

Download PDFMature Fields

Validating real-time data and power transfer between wired drill pipe and BHA

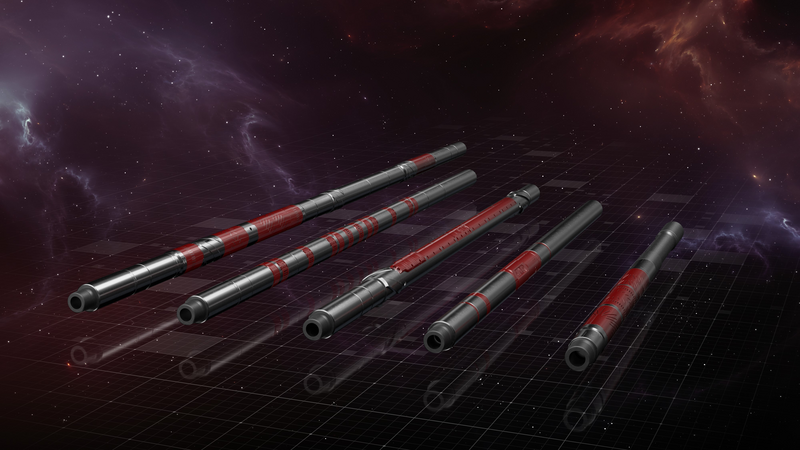

Wired drill pipe (WDP) technology helps reduce drilling time, improve well placement, and increase wellbore quality, which are factors that lead to higher production rates. Beyond high-speed data transmission, some WDP systems can deliver electric power along the drill string. This unlocks simpler, more efficient bottomhole assemblies (BHAs).

In Norway, Halliburton conducted a field test to validate real-time data and power transmission with the StreamStar™ wired drill pipe interface system. The test confirmed reliable connectivity between the iStar® drilling and logging platform and a third-party WDP system under realistic drilling conditions.

Operators who deploy wired drill pipe (WDP) technologies that transmit high-speed real-time data and electric power must validate system interoperability under realistic drilling conditions. A key challenge is to integrate logging-while-drilling (LWD) tools and rotary steerable systems (RSS) with third-party WDP platforms.

To address this, Halliburton conducted a field test in Norway to verify consistent data and power transmission between the iStar platform and a third-party WDP system using the StreamStar interface.

Halliburton deployed the StreamStar system to establish a direct interface between the iStar platform and help ensure a third-party WDP system. Designed to manage real-time, high-speed data flow and deliver continuous electrical power, the system facilitated seamless communication through the wired network.

The test simulated live drilling conditions and confirmed the system’s ability to operate without traditional downhole batteries. Halliburton evaluated data and power transfer systems across multiple depths to enable consistent and reliable performance.

kbps real-time data rate and power delivery

continuous downhole data acquisition while drilling

The StreamStar system integrates with the iStar platform and a third-party WDP system. It enabled continuous downhole data acquisition while drilling to a total depth of 279 m. The system transmitted real-time data at rates up to 200 kbps and delivered electrical power to operate iStar® LWD tools – without traditional downhole batteries.

This field test confirmed the reliability of the StreamStar interface under realistic drilling conditions. It also validated the system’s ability to simplify bottomhole assembly architecture, reduce nonproductive time, and support faster, data-driven decisions during well construction.

Offers a digital transformation of drilling solutions to reduce operational risks and ensure consistent well delivery.

Fully digital and web-enabled to monitor and control drilling and logging operations from anywhere

High-speed data through wired drill pipe for faster drilling and geosteering decisions.