Search

Search

Search

Search

Continuous surface power and real-time data optimize closed-loop automation for superior well delivery

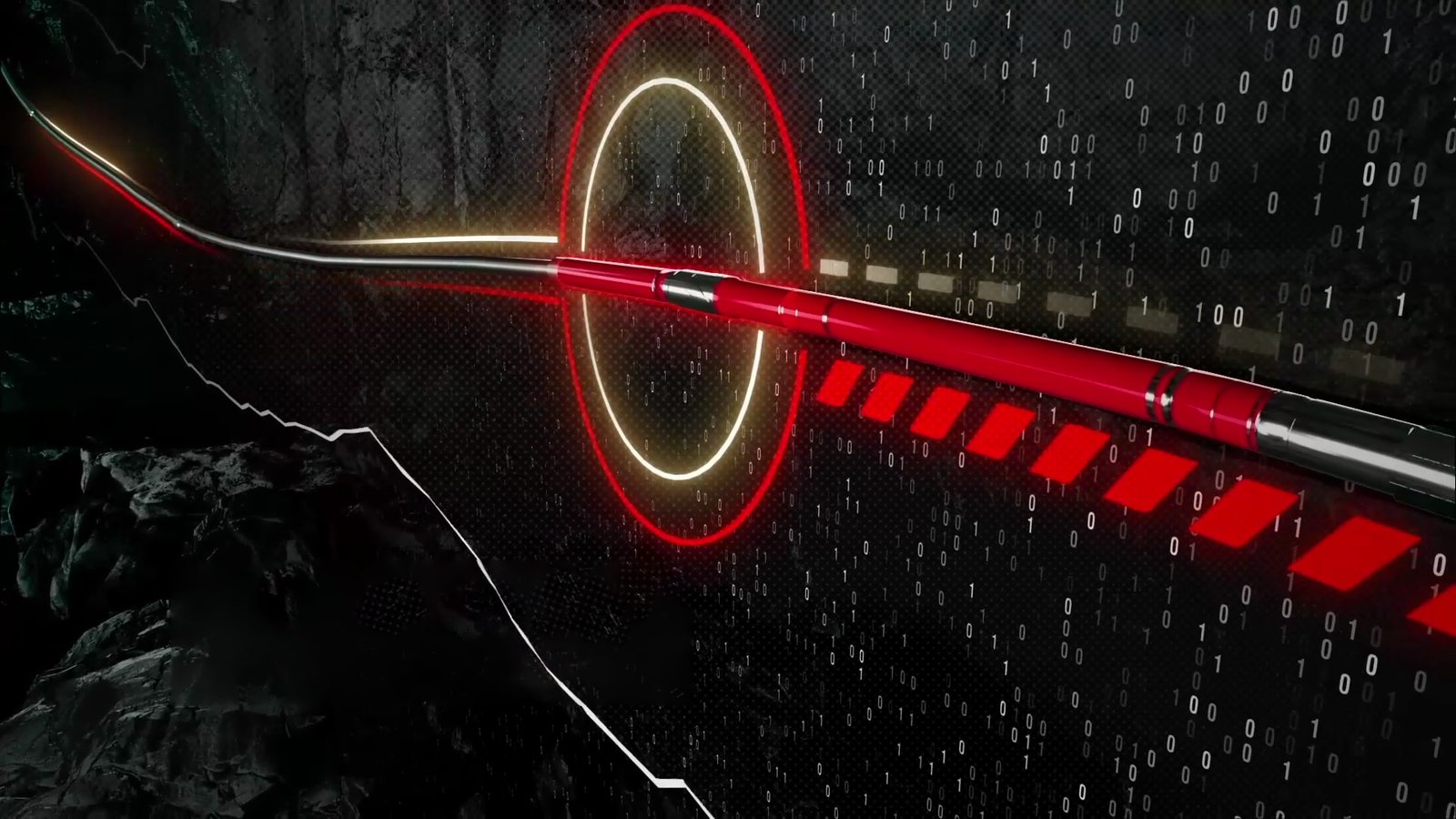

talk to an expertThe StreamStar™ wired drill pipe interface system delivers continuous high-speed data and electrical power through wired drill pipe, enabling real-time control and improved drilling performance. Designed to complement automation, geosteering, and remote operations, the system helps operators reduce nonproductive time and optimize well placement.

StreamStar™ system is the first-to-market solution that fully activates the electrical power capabilities of wired drill pipe. Bidirectional communication allows instant interaction with downhole tools—regardless of pump status—giving operators greater control and visibility throughout the well construction process.

The StreamStar wired drill pipe interface system represents the latest addition to Halliburton's iStar® intelligent drilling and logging platform. It integrates with the company's LOGIX™ automation and remote operations family of solutions to execute instant commands, maintain closed-loop control, and optimize drilling in real-time.

StreamStar system delivers uninterrupted electrical power and high-speed data transmission. By minimizing reliance on downhole generators and lithium batteries, the system simplifies the bottomhole assembly (BHA), allowing sensors to be placed closer to the bit. This streamlined architecture improves reliability and reduces environmental footprint.

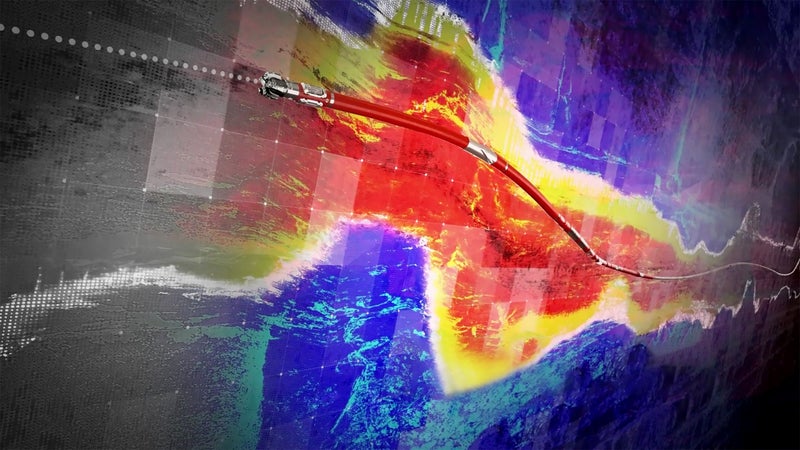

Operators benefit from real-time reservoir mapping and geosteering precision, which helps maximize reservoir contact and supports accurate well placement. The system’s ability to stream high-quality data—including borehole images and formation characteristics—empowers drilling managers and technology leaders to make faster, more informed decisions.

It transforms the wired drill string into an intelligent network that improves drilling automation, geosteering, and well integrity for precise well placement and optimized completions.

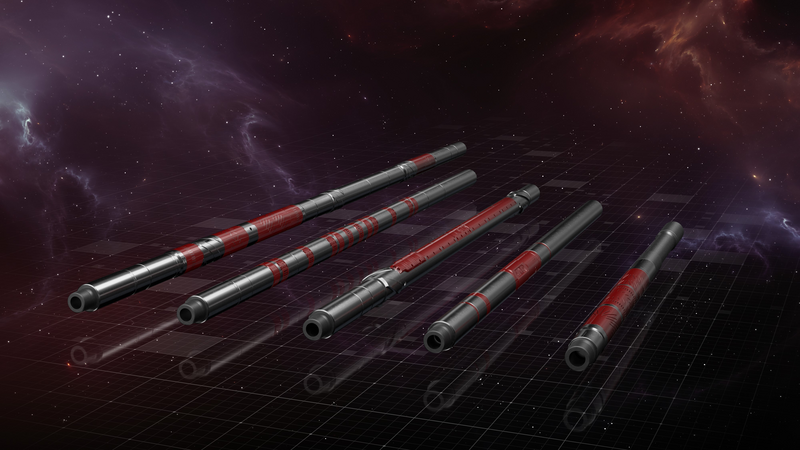

StreamStar system is available in multiple tool sizes—from 4.75-inch to 9.5-inch diameters—covering a wide range of hole sizes and operational conditions. With maximum operating temperatures of 302°F and pressures up to 25,000 psi, the system is engineered for durability and performance in demanding drilling environments.

Its robust design supports aggressive dogleg severities and high drilling parameters, making it suitable for complex well trajectories and high-performance drilling programs.

Whether you're a drilling contractor, operator, or technology decision-maker, StreamStar system offers a clear return on investment by improving drilling automation, reducing nonproductive time, and supporting consistent well delivery. It’s a strategic fit for companies advancing their digital capabilities while maintaining operational flexibility.

Fully digital and web-enabled to monitor and control drilling and logging operations from anywhere

Offers a digital transformation of drilling solutions to reduce operational risks and ensure consistent well delivery.

LOGIX™ automated geosteering redefines geosteering precision through automation, real-time intelligence, and advanced geological modeling to optimize well placement and maximize recovery.