Search

Search

Search

Search

Drilling through a transition zone while maintaining precise vertical placement

Offshore Malaysia

In a highly-congested field wheretight target tolerances demand precise wellbore placement, the operator and Halliburton Sperry Drilling employed advanced geosteering tools to drill the longest horizontal section to date for an operator in Malaysia. The section totaled 2,011 meters (6,598 feet) in horizontal length, with 1,361 meters (4,465 feet) in the primary target sand, plus 279 meters (915 feet) of horizontal section in the secondary target.

In addition to its complex S-type profile, the well required setting an additional string of casing to overcome a major collision issue, where target sands required maintaining a tight window tolerance of one meter (3.3 feet) within the true vertical depth (TVD) specified by the geologist.

Working with the customer to deliver the challenging well plan, Halliburton provided Geo-Pilot® rotary steerable systems and a triple combo measurement/logging-while-drilling (M/LWD) suite for accurate formation evaluation and precise wellbore placement, as well as the XR™ Reamer borehole enlargement tool for hole enlargement while drilling.

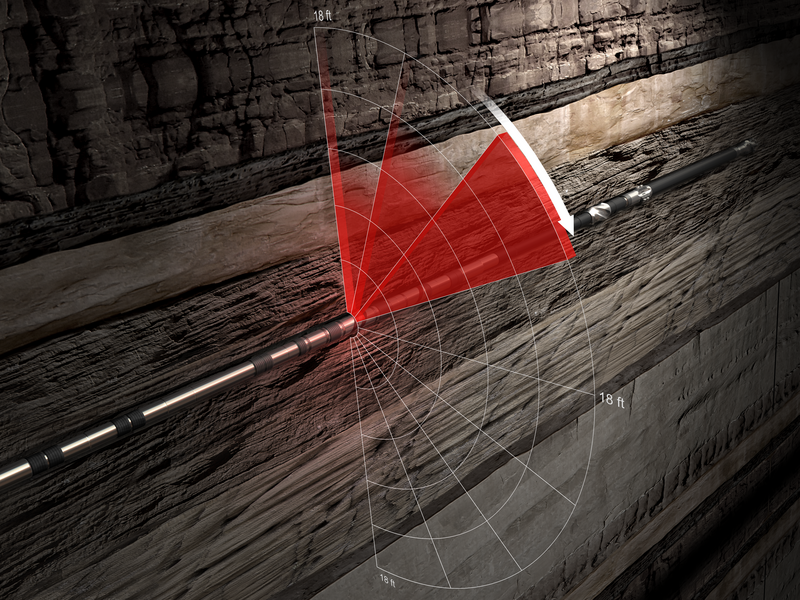

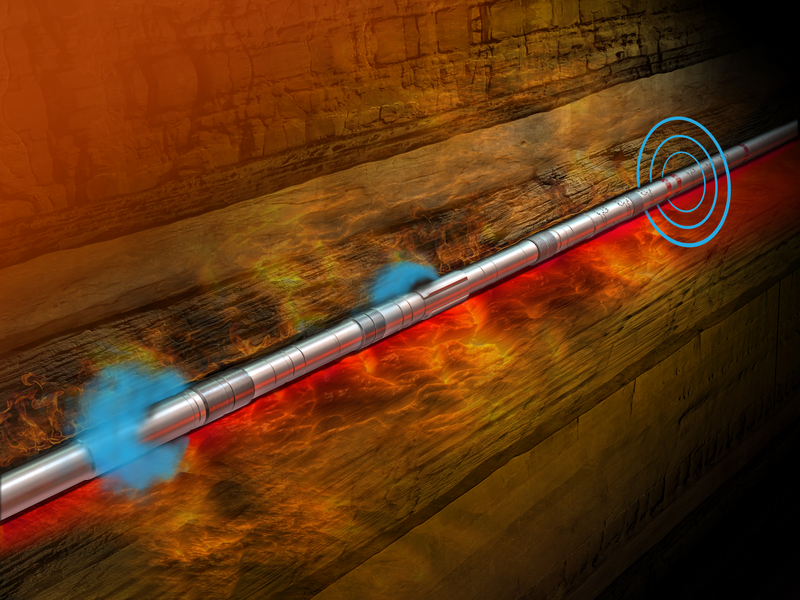

The InSite ADR azimuthal deep resistivity sensor and StrataSteer 3D geosteering service played a key role in successfully geosteering in the narrow target sands. Thee InSite ADR sensor delivers true directional resistivity measurements rather than merely indicating a resistivity change in a given direction, so it can resolve both thin and thick reservoirs. The InSite ADR sensor is able to delineate individual layers, even in transition zones such as this well presented, where both oil and water are present in the region between an oil zone and a water zone. By including a conventional compensated resistivity sensor Case History Measurement/Logging While Drilling HAL32992 In the longest 8 ½-inch x 9 ½-inch horizontal drain to date in Malaysia, Halliburton’s InSite ADR™ azimuthal deep resistivity sensor and StrataSteer® 3D geosteering service provided a complete picture around the borehole, enabling precise geosteering within narrow targets. together with the geosteering resistivity capability, the InSite ADR sensor provides azimuthal resistivities ranging from shallow to deep, creating a complete picture in all directions around the borehole.

With the well nudged off safely and steered clear of nearby wells, the pilot hole was drilled, and the under reamer run was made prior to running and cementing the 18 5/8-inch casing. The remaining well sections were drilled according to plan, with the 12 1/4-inch section using the Geo-Pilot® rotary steerable system with an M/LWD suite to successfully land the well horizontally at 1,167 meters (3,829 feet) TVD in one run.

This was followed with delivery of the 8 ½-inch x 9 ½-inch horizontal interval using a Geo-Pilot 7600 series rotary steerable system with a lower stabilized housing matched with a Geo-Pilot long gauge FMF3553ZR bit. The matched system enhances stability, helping to eliminate holespiraling and minimize wellbore tortuosities. The five-bladed bit design features a dual-row cutting structure of highly abrasion-resistant Z3® cutters backed by R1™ PDC backup cutters to limit depth of cut, delivering a moreconstant, controlled rate of penetration that yields a higher average penetration. In addition, the M/LWD suite (AGR™ azimuthal gamma ray sensor, ALD™ azimuthal lithodensity sensor, CTN™ compensated thermal neutron sensor, pressure while drilling sensor, AcoustCaliper™ sensor, InSite ADR sensor) and StrataSteer 3D service were used.

This integrated solution successfully delivered a total horizontal section of 1,361 meters (4,465 feet) in the primary target sand, and then drilled through tight silt to penetrate the secondary target.

When gamma and density tools indicated the well had drilled out of the secondary target sand, the customer’s existing structural model and horizontal wellplan seemed to confirm that the well had drilled into the overlying shale. Under the circumstances, it seemed prudent to either consider this the final target depth of the well or try to drill back down into the sand.

However, employing the StrataSteer 3D geosteering service and resistivity measurements from different depths of investigation, the InSite ADR sensor data clearly showed that the local structure was shallower than modeled and the narrow target sand was actually above the tool. The well was drilling near the bottom of the sand— not out of it. Based on this information, the decision was made to continue drilling, and the wellbore was twice nudged a mere halfmeter (1.64 feet) to remain in the pay and complete the entire horizontal drain in one run.

meters drilled

USD saved in well construction

record-length horizontal drain delivered

The record-setting performanceis not only thelongest 8 ½-inch x 9 ½-inch horizontal drain for this operator, but it also resulted in well construction savings of approximately US $500,000.

A total depth of 3,499 meters (11,480 feet) was drilled with a total lateral section of 2,011 meters (6,598 feet) making it the longest horizontal run in the world using a 6 ¾-inch InSite ADR sensor. Following Halliburton’s process to ‘model, measure and optimize,’ a more accurate understanding of theformation in all directions around the borehole was realized, and it was possible to maximize wellbore exposure in these narrow target sands. The record-length horizontal drain delivered 1,361 meters (4,465 feet) in the primary target sand, plus 279 meters (915 feet) in the secondary target, far exceeding the planned 90 meters (295 feet). The improved data made it possible to avoid unnecessary operations and instead resulted in drilling an additional 189 meters (620 feet) of horizontal hole.

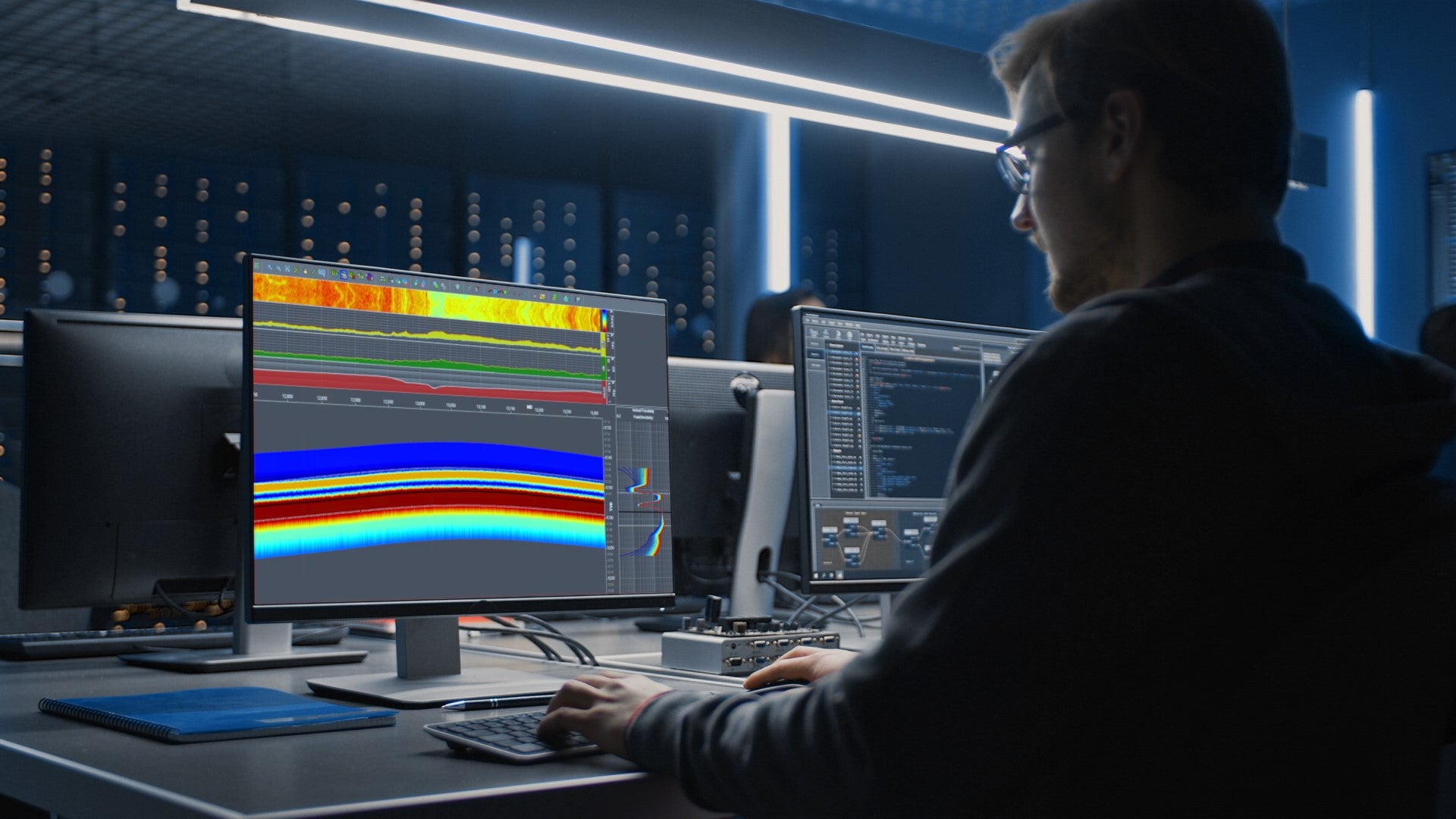

ADR's deep-reading geosteering and resistivity sensors deliver over 2,000 unique measurements for accurate petrophysical analysis and wellbore placement.

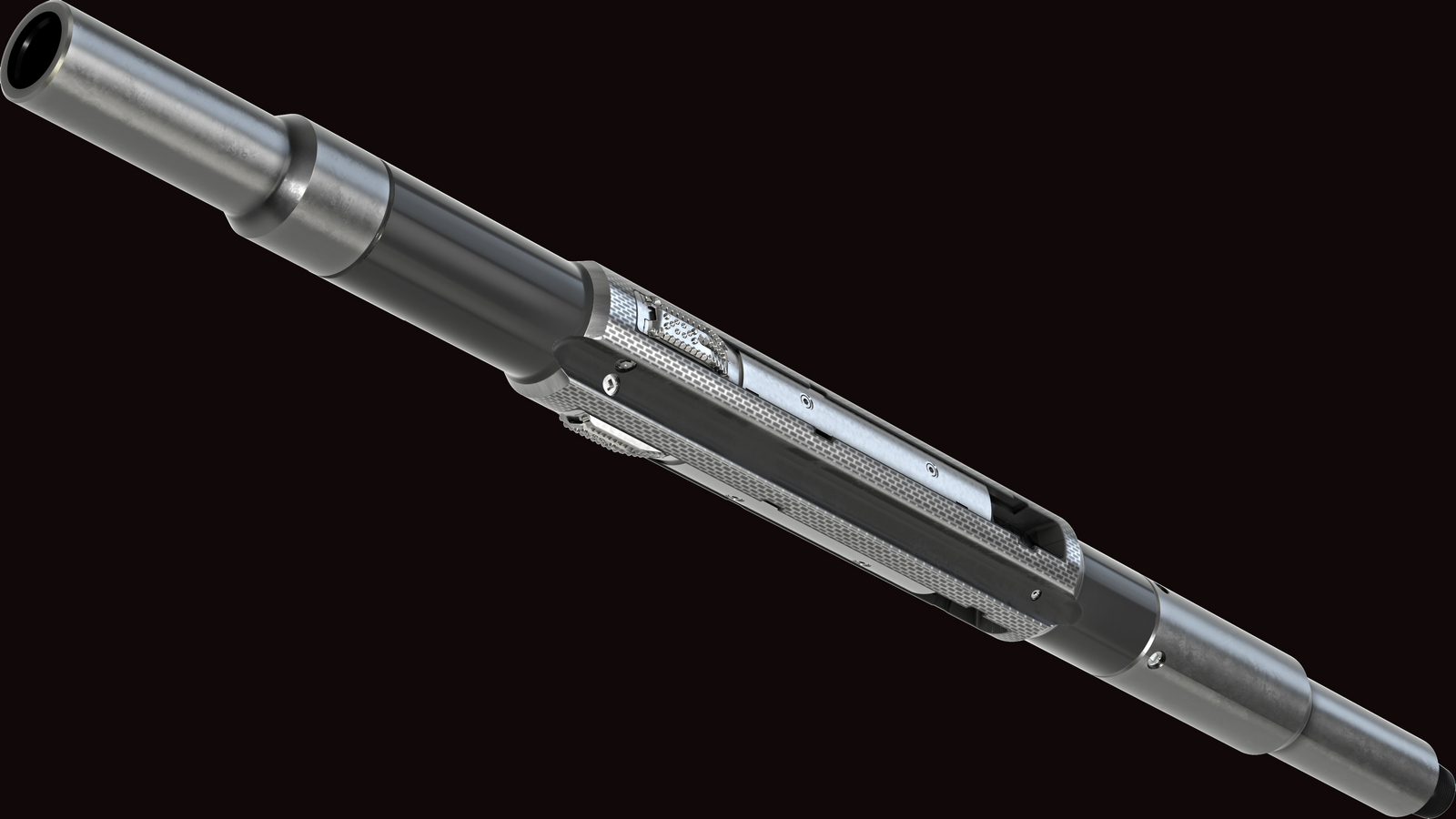

The Halliburton Geo-Pilot® rotary steerable systems (RSS) is designed to deliver unprecedented speed and precise steering.

The XR™ reamer hole enlargement tool from Halliburton is the industry leader, capable of expanding the wellbore 1.5 times the initial diameter.

Designed for extreme high-temperature and high-pressure environments.