Search

Search

Search

Search

Deep water

Conducting accurate reservoir evaluation and fluid sampling

In a deepwater operation with water depth of over 3,397 ft (1,035 m) in Angola, the operator faced a challenge to maximize production from a reservoir with little detailed information. This operation in Angola involved the usual drilling challenges associated with deepwater environments, as well as substantial logistical constraints. Even with combining these challenges, Sperry Drilling successfully managed to deliver the first LWD sampling service to the client with samples of representative reservoir fluids.

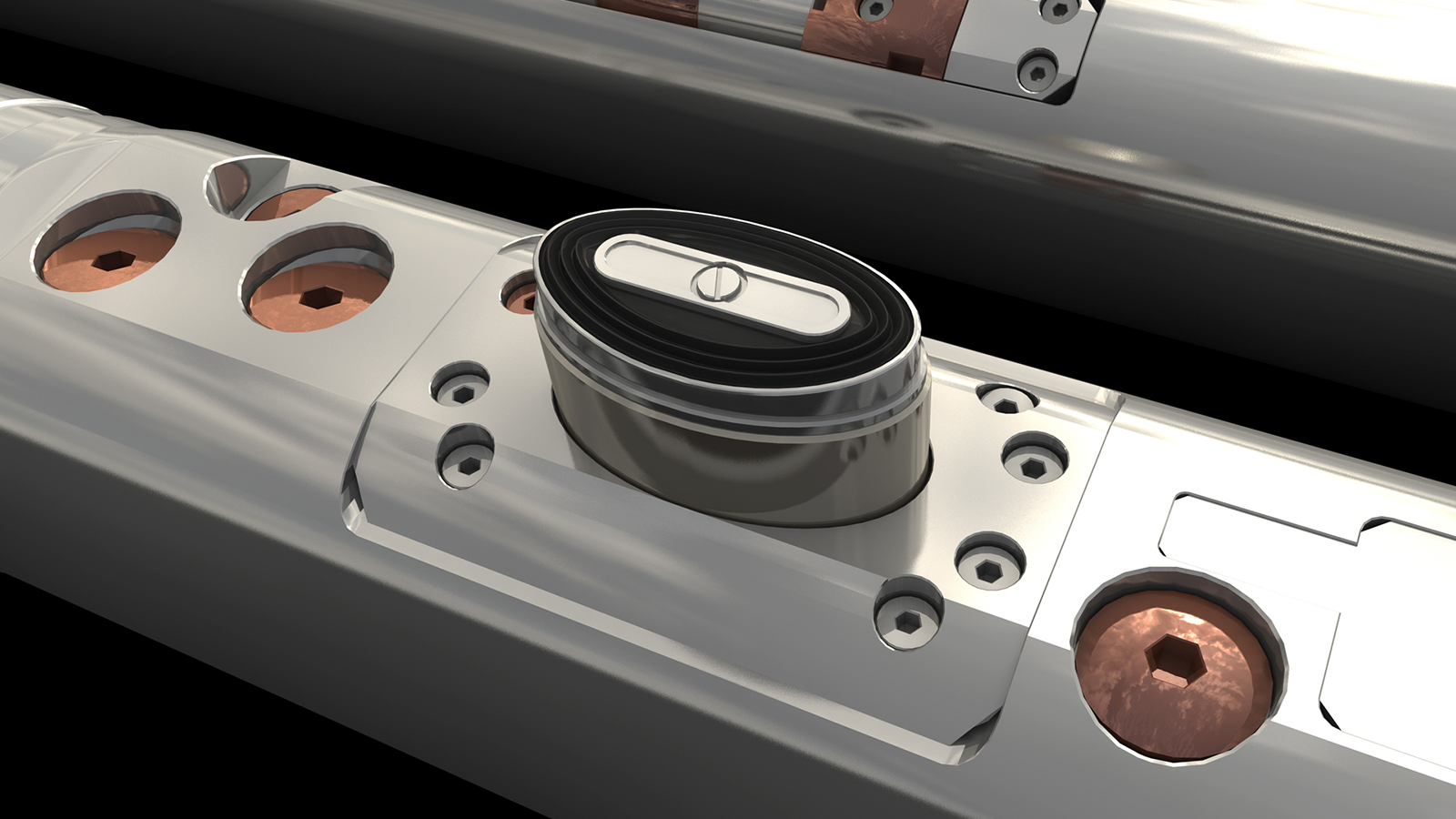

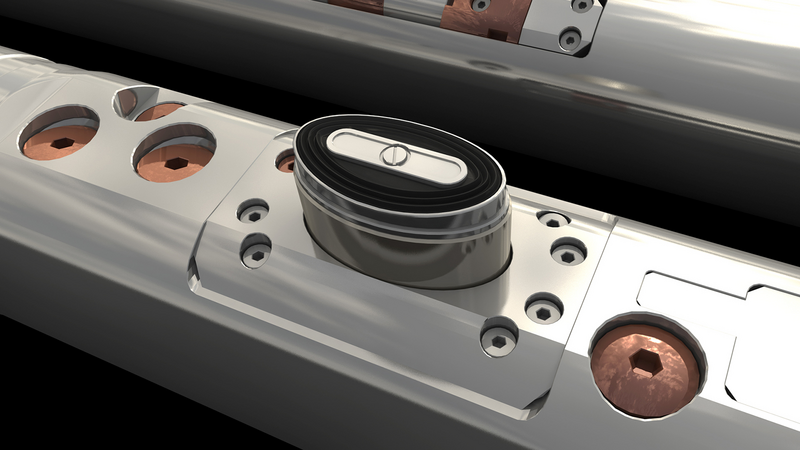

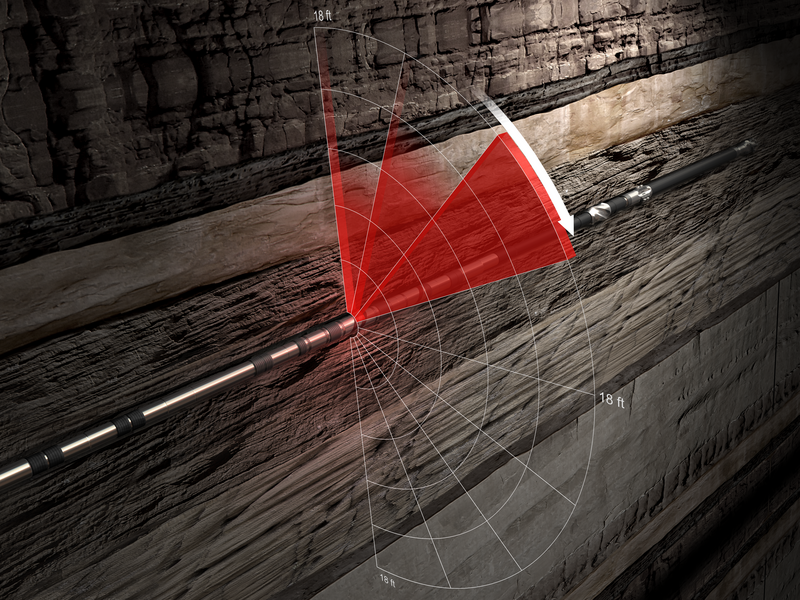

To maximize reservoir evaluation, Sperry Drilling recommended a penta combo service that included an azimuthal deep resistivity (ADR™) sensor for deep resistivity; an azimuthal lithodensity (ALD™) sensor and a compensated thermal neutron (CTN™) sensor for porosity and density analysis; an azimuthal focused resistivity (AFR™) sensor, along with an at-bit gamma (ABG™) sensor, to provide resistivity and gamma imaging for geostopping; a dual gamma ray (DGR™) sensor for gamma measurements; and the GeoTapTM IDS sensor for formation testing and fluid sampling.

The initial LWD combo set was drilled without the GeoTap IDS sensor to a total depth (TD) of 8,478 ft (2,584 m) and successfully identified coring points for the operator, with the ABG and AFR sensors identifying the top boundary of the reservoir. Then, the GeoTap IDS sensors was added to the LWD combo to log and drill to final TD of 9,183 ft (2,799 m). During this final section, multiple pressure tests were taken to determine the mobility and best depth to capture fluid samples, as analysis and decisions were made at the operator’s office.

USD saved

filtrate contamination in a deepwater well

Fluid sampling and pressure-volume-temperature (PVT) analysis allow the operator to reveal formation details to aid with reservoir quality, production facility designs, and refining requirements. In deepwater operations, fluid sampling while drilling is optimal to minimize mud filtrates to the formation and contamination level in the samples, saving hours of deepwater rig time because of less cleaning or pump-out time. The GeoTap IDS sensor collected four samples with only 3.3 percent to 8.1 percent contamination, satisfying the operator’s requirements in a very reduced time. The client claimed that these results enable the company to “forecast potential substantial rig-time savings on some future operations.” As the client was satisfied with the GeoTap IDS fluid samples, the operator saved an estimated two days of rig time in comparison with the wireline service, estimating a total savings of US$1.5 million.

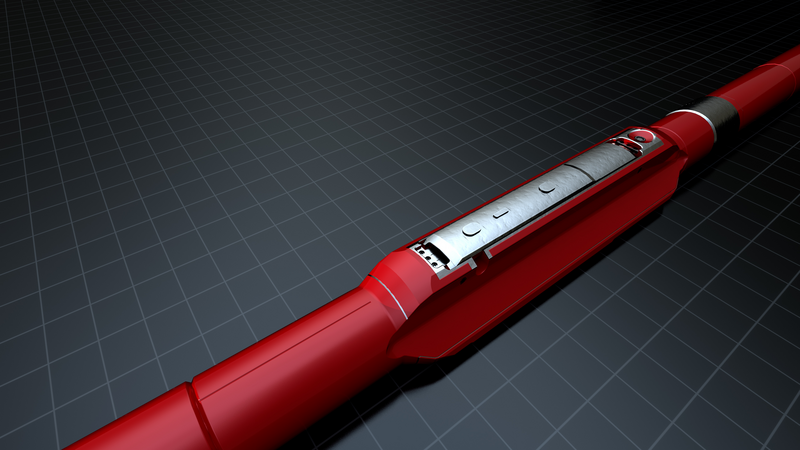

Fluid identification and sampling solution.

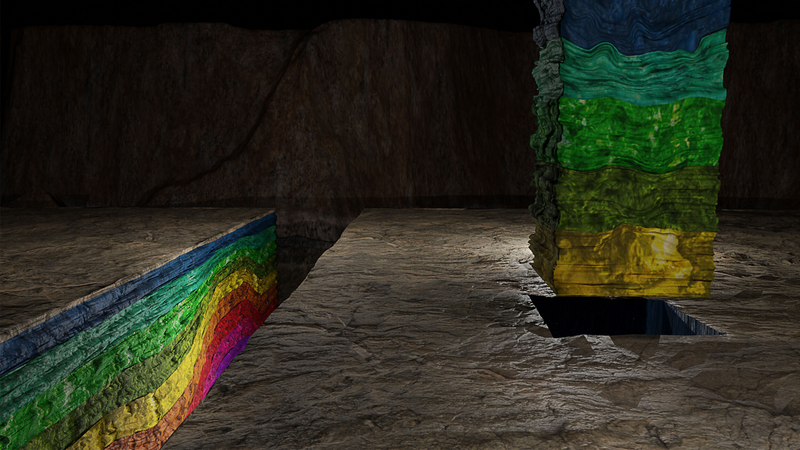

ADR's deep-reading geosteering and resistivity sensors deliver over 2,000 unique measurements for accurate petrophysical analysis and wellbore placement.

High resolution logging-while-drilling borehole images.

Accurate real-time density imaging in oil-based and water-based mud systems.