Search

Search

Search

Search

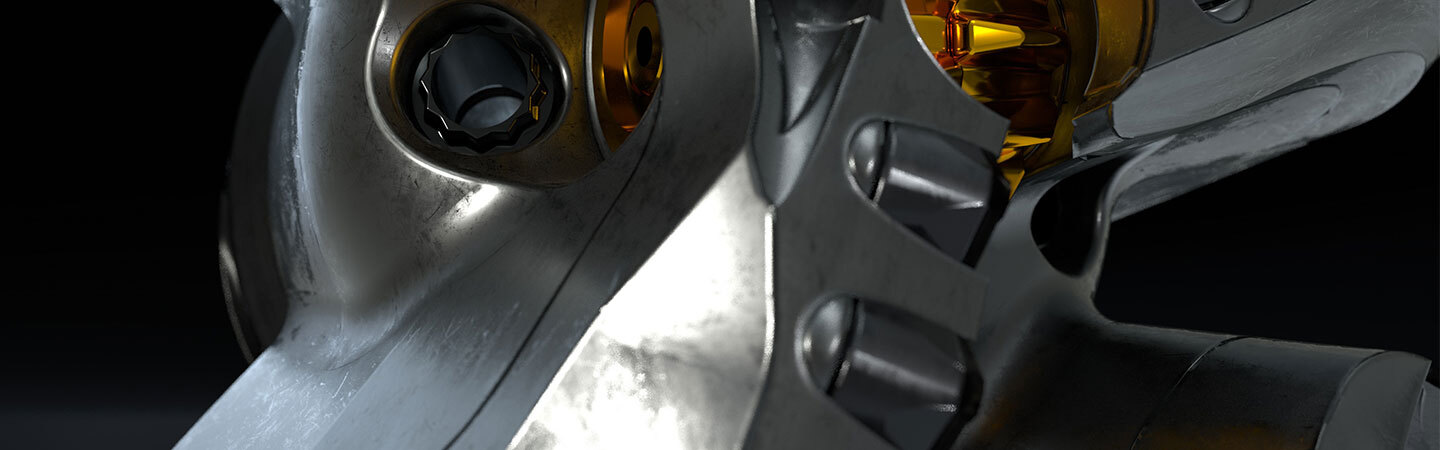

Halliburton’s Crush & Shear hybrid drill bits place roller cones in the center of the bit for efficient formation crushing and move the PDC cutters to the shoulder for maximum rock shearing. They are engineered to take advantage of rock failure mechanics while providing lateral stability.

The hybrid bit’s durable carbide rolling elements provide extreme levels of strength and abrasion resistance. There are multiple carbide grades to suit various demanding applications. This technology’s robust all-carbide cones and carbide-reinforced bearing components make the Crush & Shear hybrid bit ideally suited for the toughest of downhole drilling environments.

case study / oklahoma

Cost of the interval reduced, saving the customer over USD $120,000

read the case studyCrush & Shear drill bits help operators drill faster with better control in hard rock, vibration-prone wells and traditional curve applications.

Crush & Shear hybrid bits place polycrystalline diamond compact (PDC) elements alongside rolling elements, which optimize the cutting mechanism for each region of the bit. This means higher rates of penetration, improved lateral stability, and minimal torque fluctuations.