Search

Search

Search

Search

BHKA™ plug setting disconnect tool enables placement of 472-m long cement plug, isolates pilot hole, and allows deviation to horizontal section

Download PDFUnconventionals

Place kickoff plug efficiently and isolate 470-m openhole section

Argentina

Operators often drill and abandon pilot wells during exploration campaigns, which requires a cement plug for proper isolation. Conventional balanced cement plugs usually require long cement setting times and have a low success rate because of high levels of contamination and cement plug length limitations.

An operator in Argentina required a 472-m long cement plug in a 6.86-in. openhole section of a vertical pilot well to abandon the lower section and deviate to a new horizontal section. Both conditions can result in unsuccessful cement plug operations and long, expensive remedial operations.

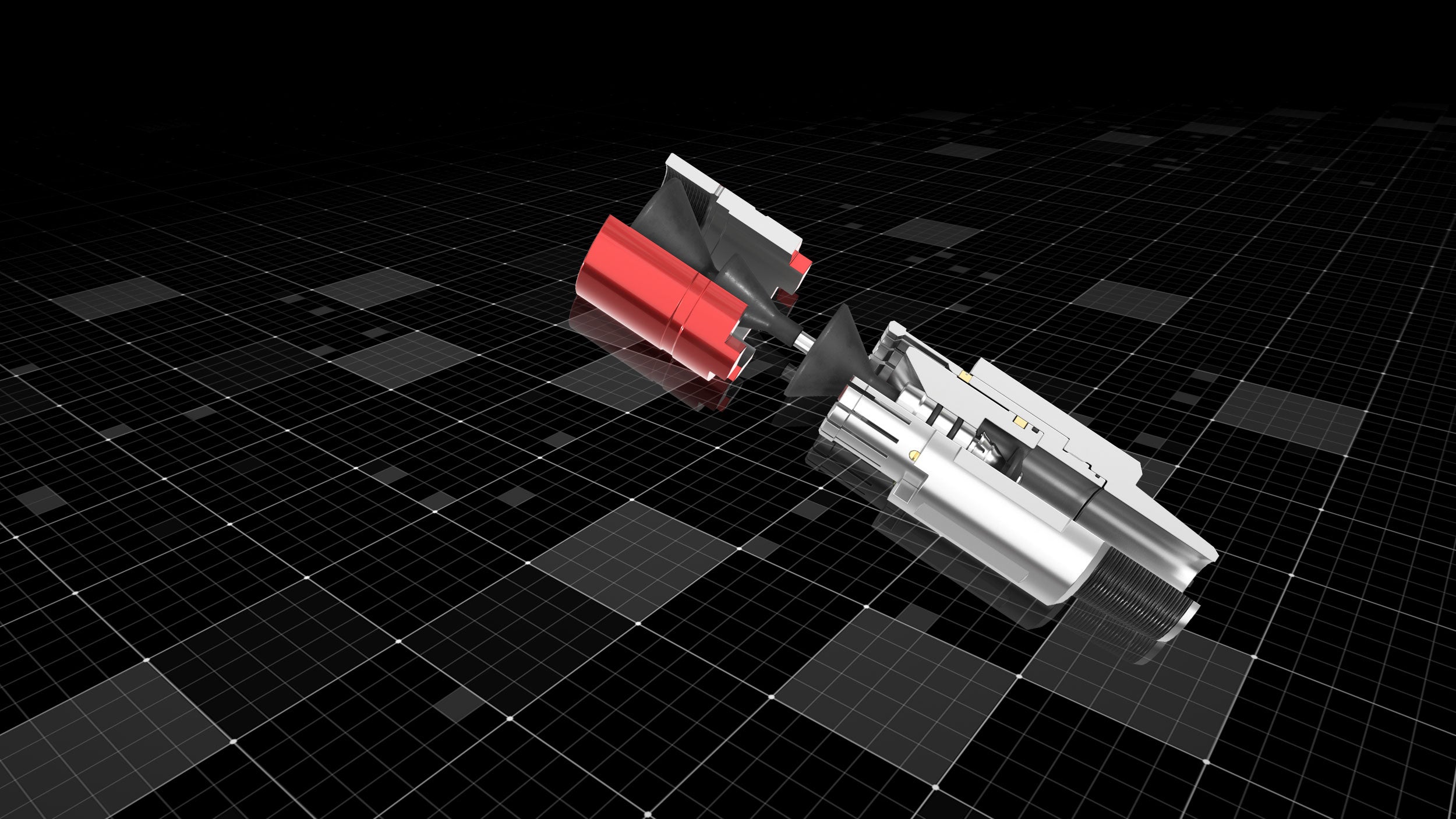

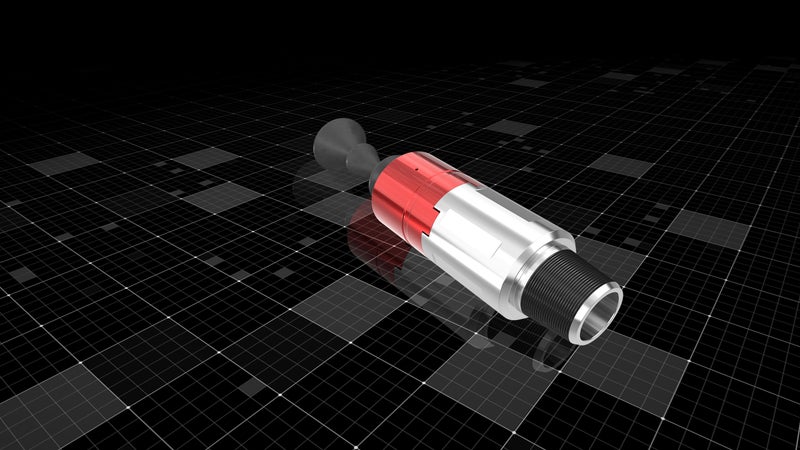

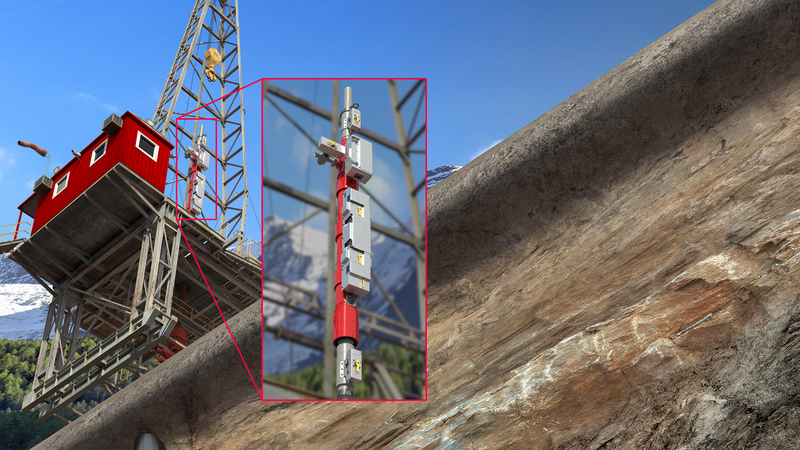

Halliburton proposed deployment of the BHKA™ plug setting tool with a fiberglass sacrificial tailpipe and a tailored cement slurry to enable the safe placement of a single, undisturbed, 427-m cement plug.

The displacement dart and BHKA tool’s safe disconnection help minimize cement contamination and shorten cement setting time. Halliburton designed the cement slurry in accordance with best practices to minimize the risk of circulating losses and improve fluid displacement and final cement placement. A Commander™ 500 cement head was also deployed to promote a safe, positive dart release and maintain an effective barrier during the wellbore circulation and cement operation.

Long cement plug placed

Tagged 5 m above plan

Hours rig time saved

The workstring was run in hole (RIH) to a final depth of 2684 m measured depth (MD) as designed, with no impact to string torque and tensile strength integrity; the well was circulated without indication of fluid loss. The cement operation followed the design of service.

A Clear tailpipe release, indicated by the 2,403-psi differential pressure spike, was observed at the end of cement displacement. No cement was observed at the surface during subsequent wellbore cleanup circulation. This indicated that the top of cement (TOC) was below the tool’s position, and that the solution allowed for string integrity throughout the entire operation.

After the setting time was complete, the top of the cement (TOC) was found 5 meters above the planned level. This allowed the well deviation to proceed as planned, without affecting the isolation of the lower section. Wait on cement (WOC) was eliminated between balance cement plugs, helping save an estimated 50 hours of rig time.

The Halliburton BHKA™ plug setting disconnect tool simplifies cement plug placement when necessary during well construction or abandonment operations.

Enabling rotation and reciprocation to improve cement coverage to reduce communication between frac stages and maximize asset value.

Designed for offshore operations to surface launch balls or darts in order to operate subsea plug sets and associated tools.