Search

Search

Search

Search

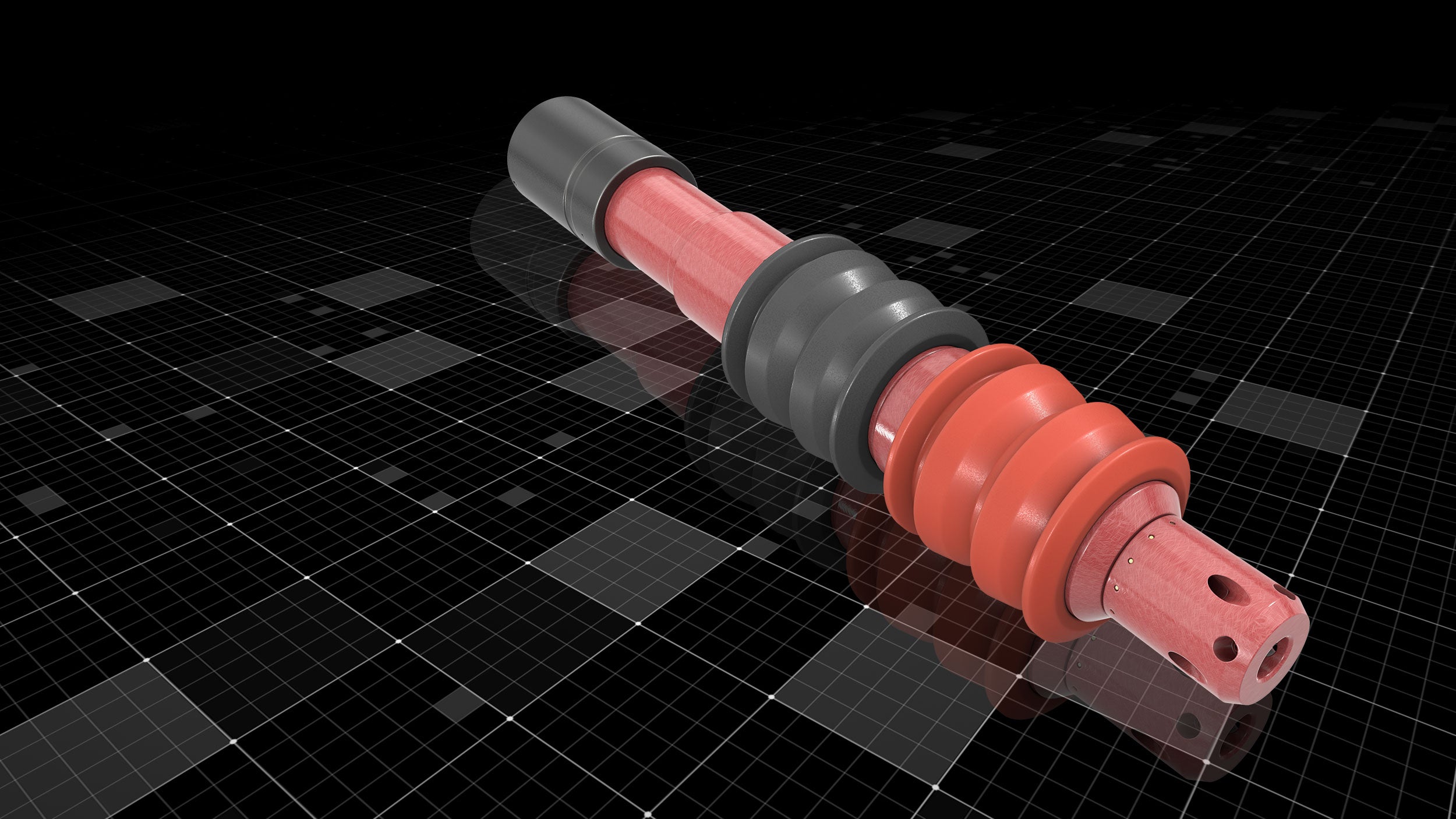

Designed to provide mechanical separation and prevent contamination between cementing fluids pumped down the landing string

Talk to an expertFor over five decades, Halliburton has designed subsurface release (SSR®) plugs intended to cement casing string from subsurface hangers. These plugs enable precise cement slurry placement in offshore and liner operations. Accurate deployment is crucial for fluid separation, contamination prevention, zonal isolation, and avoiding costly remedial operations and environmental hazards. As the industry’s first patented reinforced plastic composite plug system, SSR-II™ plugs offer improved reliability and drillability compared to conventional aluminum plug assemblies, especially in high-pressure demanding operations.

Released ahead and behind the cement slurries, the plug-releasing darts provide mechanical separation and prevent contamination between cementing fluids when traveling down the landing string.

The unique bottom plug bypass design of the SSR-II plug system creates an unrestricted flow area on the landed plug.

Commonly used aluminium mandrels are replaced with high-strength composite materials to reduce drill-out time and drill-bit damage.