Search

Search

Search

Search

Dual-plug SSR-II™ cement plug system delivers improved annular cement barrier for production liner equipped with VersaFlex® expandable liner hanger

Download PDFMature Fields

Improve annular isolation quality in critical production zone

Ecuador

Most well designs in Ecuador use a cemented production liner to isolate the main geological target. In the Oriente basin, operators typically position the uppermost objective near the liner top. This placement allows the electric submersible pump (ESP) to remain inside the previous cemented casing while staying close to the reservoir.

During cement operations, operators commonly use a bottom plug to minimize contamination in the leading-edge cement slurry. While this best practice is standard for full casing strings, it adds complexity and risk to liner operations. As a result, operators opt for top-plug only designs during liner cement operations.

Operators have historically struggled to achieve full zonal isolation across the entire open hole and liner overlap using top-plug only options. The main issue is excessive contamination at the cement slurry’s leading edge near the liner top, which leads to a cement sheath with poor compressive strength.

To improve results, contingency designs were implemented, such as increased cement slurry volumes. However, this raised operational risks due to the hanger running tool exposure to the cement slurry above the top of liner (TOL) and has delivered limited success.

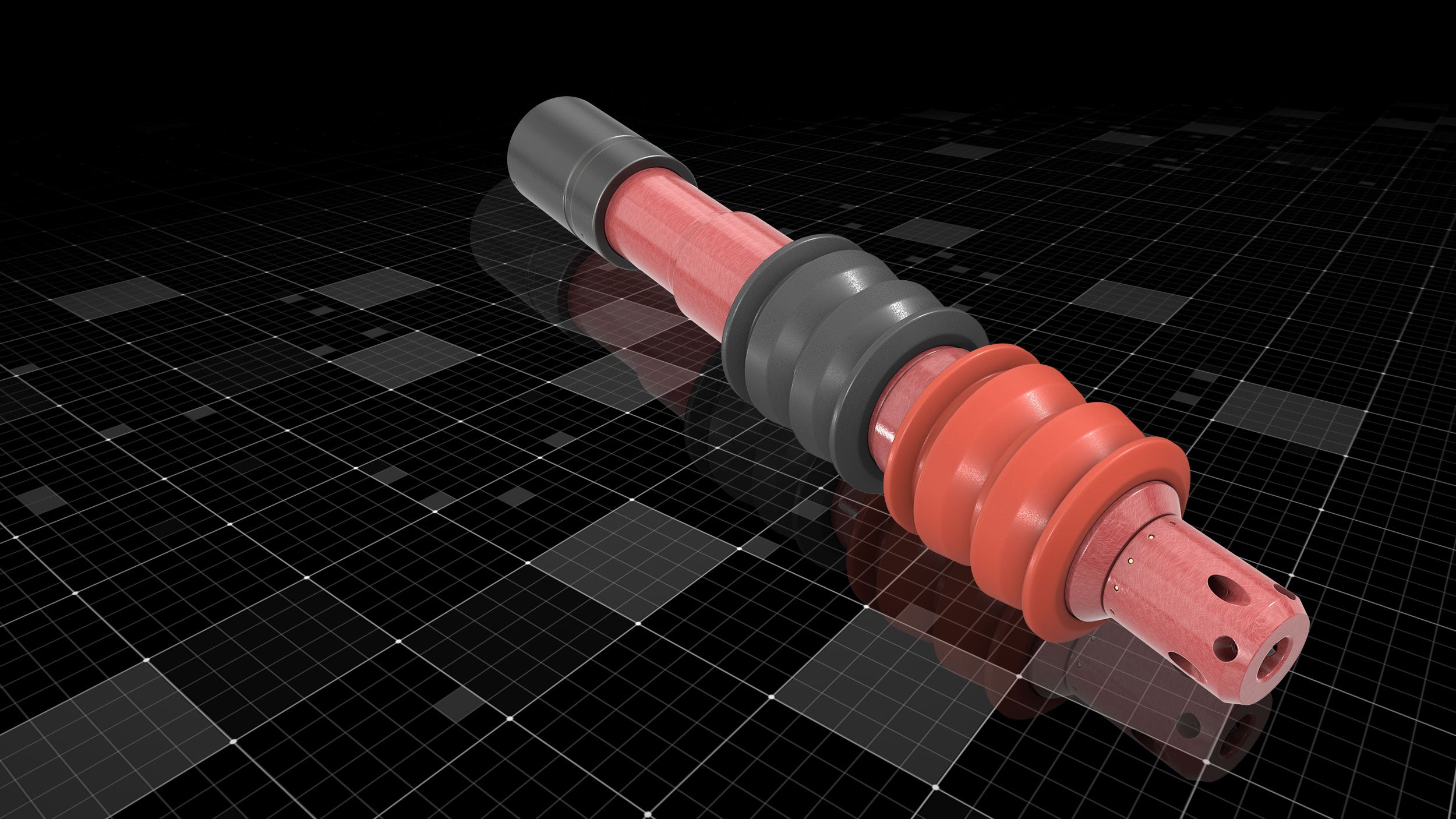

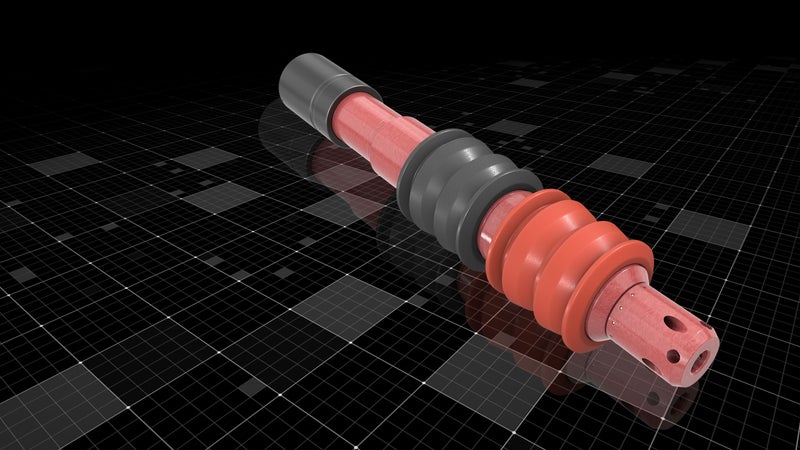

After an in-depth analysis of the cement design using iCem® cementing service 3D modeling capabilities, Halliburton engineers confirmed it was necessary to add a bottom plug. The bottom plug serves as a mechanical barrier to contain the cement slurry while it travels down the landing string and liner. This was required to increase mud displacement and cement slurry coverage in the annulus and maximize the isolation up to the TOL. Equipped with these results, Halliburton recommended a high-strength, 7-in. dual-plug SSR-II™ cement plug system for the operation.

Dual plug SSR system

Expansion of liner hanger on plug bump

Confirmed barrier success

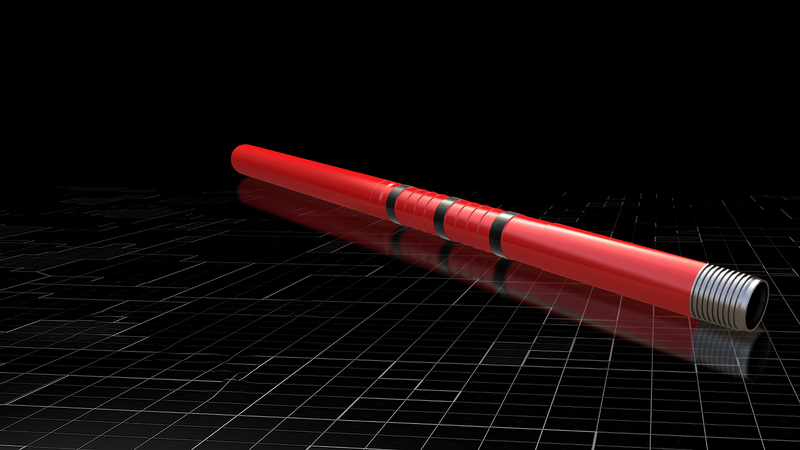

The 7-in. liner was run to planned depth and cemented flawlessly with the NeoCem™ system. The Commander™ 350 cement head was used to provide pipe rotation during cement operations. The dual-plug SSR-II™ system performed as planned, with clear indications of bottom plug release and bypass, followed by top plug release and successful landing on the landing collar. This allowed full expansion and setting of the VersaFlex® expandable liner hanger without additional steps or contingencies.

Post-job cement bond log (CBL) analysis confirmed zonal isolation, with 2 mV in the production zone and an average of 4 mV improvement compared to a twin well cemented with a top-plug only solution.

The successful deployment of the dual-plug SSR-II system increased operator confidence and paved the way for future implementations.

SSR-II™ cement plugs are designed to provide mechanical separation and prevent contamination between cementing fluids pumped down the landing string.

Delivers a low-to-moderate load bearing without sacrificing its gas-tight sealing capability or reliability