Search

Search

Search

Search

An intelligent fracturing ecosystem that enables frac automation, digital operations, and remote connectivity

talk to an expertOCTIV® digital fracturing services enable frac automation, digital operations, and remote connectivity across all aspects of Halliburton’s hydraulic fracturing business.

OCTIV services are at the core of Halliburton’s intelligent fracturing ecosystem. The services enable intelligent automation to maximize the performance and efficiency of equipment and operations.

The services provide a new level of visibility through remote connectivity, enabling Halliburton and its customers to accelerate operational change.

The ecosystem consists of these applications:

Product Announcement

The OCTIV® auto frac service is the latest addition to the OCTIV® digital fracturing services. OCTIV automates digital workflows, information, and equipment across all aspects of our fracture operations. The result is safer, more efficient operations for Halliburton and its customers.

read press releaseOCTIV is more than simple task automation. Our fracture operations are digitally automated, including all processes and surface equipment.

OCTIV automates our spread to maximize performance and efficiency. It applies digital workflows that streamline how we operate, and it connects experts in field with decision makers at the office.

OCTIV conducts an entire frac spread as a single, fully automated system that delivers greater equipment reliability and operational efficiency.

By integrating with thousands of sensors across a spread, OCTIV executes to plan while continuously monitoring and responding to equipment health and well conditions.

OCTIV streamlines business processes by synchronizing efforts across operations, maintenance, engineering, and supply chain. From preliminary planning to execution, OCTIV simplifies how we go to work every day.

OCTIV introduces a new level of transparency to the frac site that connects decision makers to their operations through remote monitoring and control. It provides instant insight into job progress and analytics, while enabling collaboration between stakeholders across every asset.

Integrated, fully automated spread

Sensors monitored per spread

Tasks automated each stage

North America fleet upgraded

An easy to deploy, cost-effective fracture monitoring solution for continuous measurement and visualization of the subsurface.

The Halliburton ZEUS electric fracturing pumping unit delivers higher pump rates with 5,000 hydraulic horsepower.

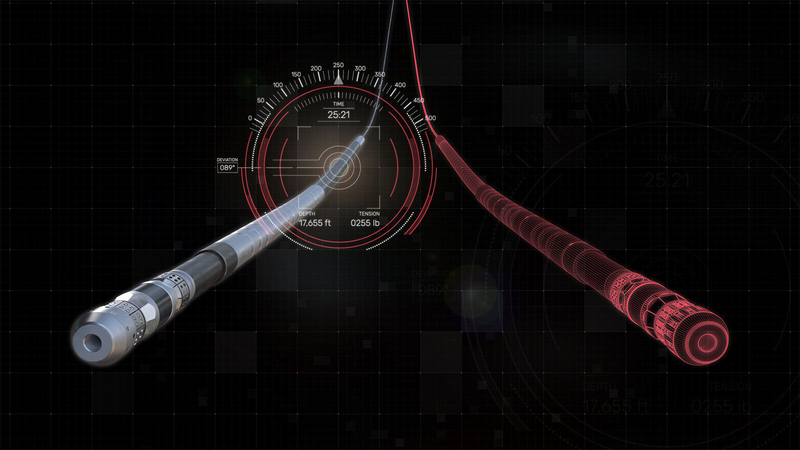

OCTIV Auto Pumpdown service controls fluid pumps and a wireline unit as a single, fully automated, closed-loop system to maximize plug and perforating performance.