Search

Search

Search

Search

V3-rated mechanical barrier support plus integral multiple-stage cementing capability

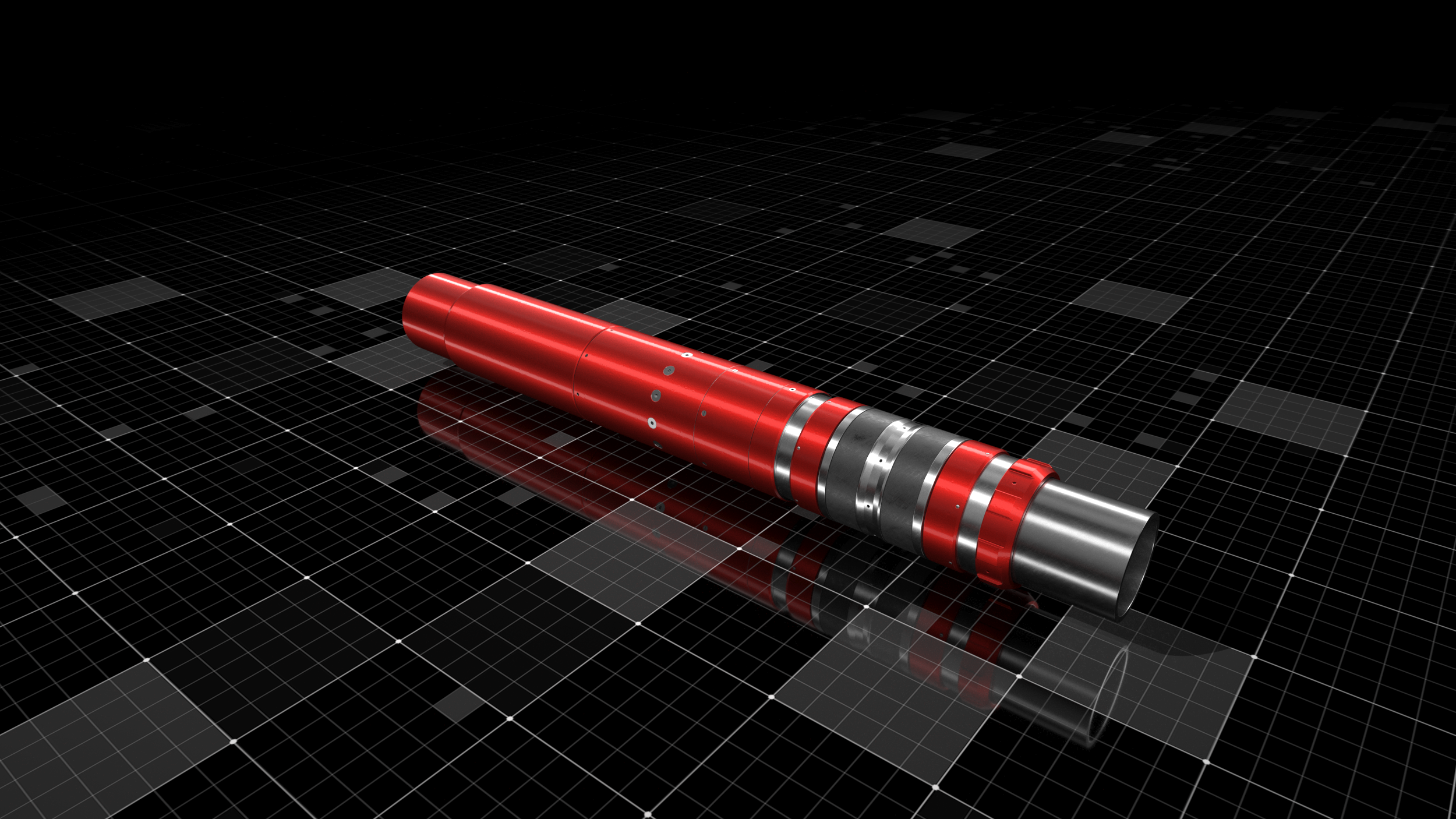

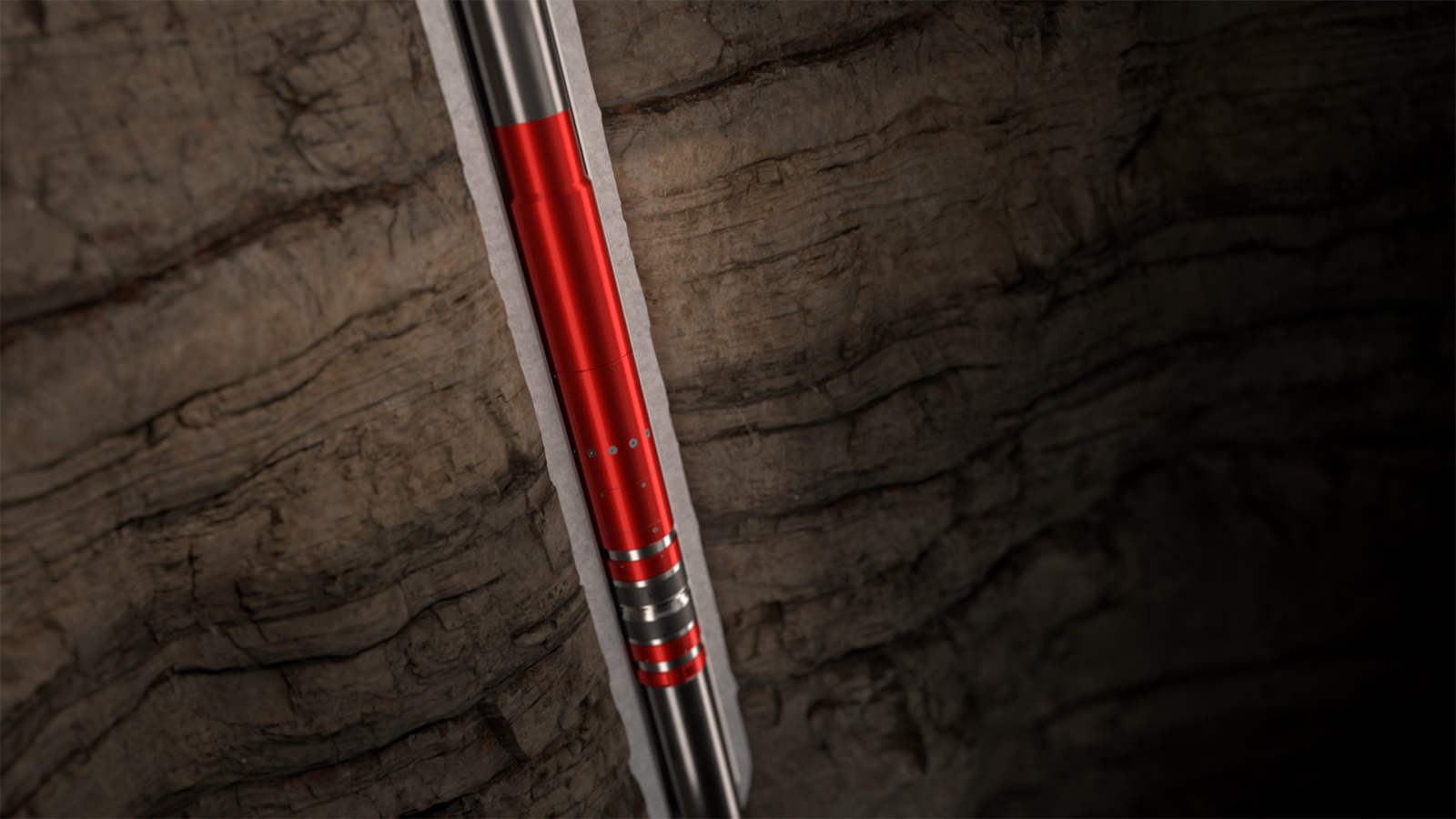

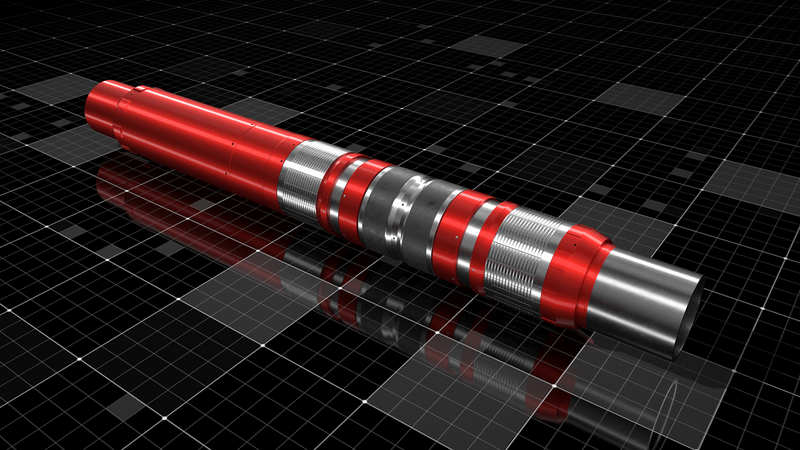

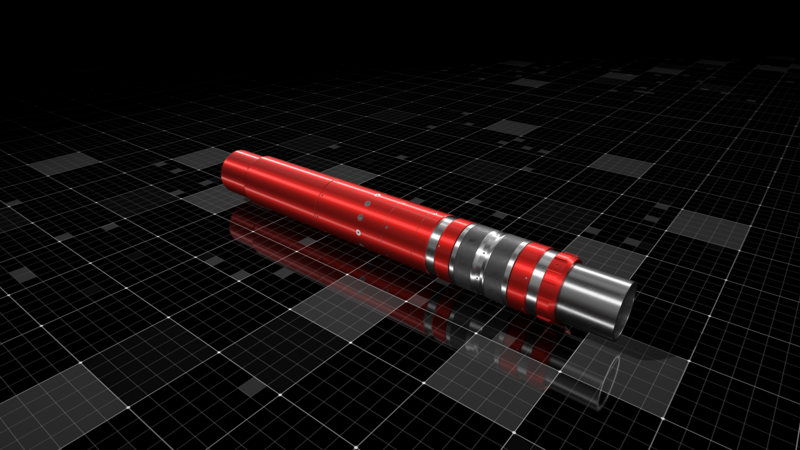

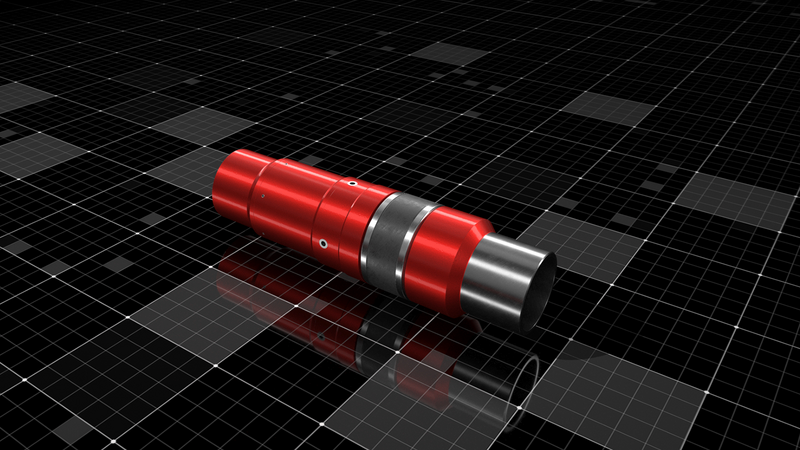

Talk to an expertLike all packers in the Obex family, the Obex IsoLock casing packer collar is mechanically set and not inflated. Using an internal ratchet mechanism to lock the compression element after it is set, results in zero weak points in the packoff, which can thereby mitigate sustained casing pressure.

PSI bidirectional packer rating

Cement flow

BPM flow rate through cementing ports

Reduction in drillable material

The Obex GasLock® casing annulus packer provides a high-pressure, gas-tight, casing-to-casing seal to mitigate annular gas migration.

The Obex IsoLock® packer collar provides V3-rated mechanical barrier support plus integral second-stage cementing capability.

The Obex EcoLock® casing annulus packer provides mechanical barrier support to prevent low pressure gas or fluid migration.