Search

Search

Search

Search

Optimize reservoir performance in deepwater and HP/HT environments

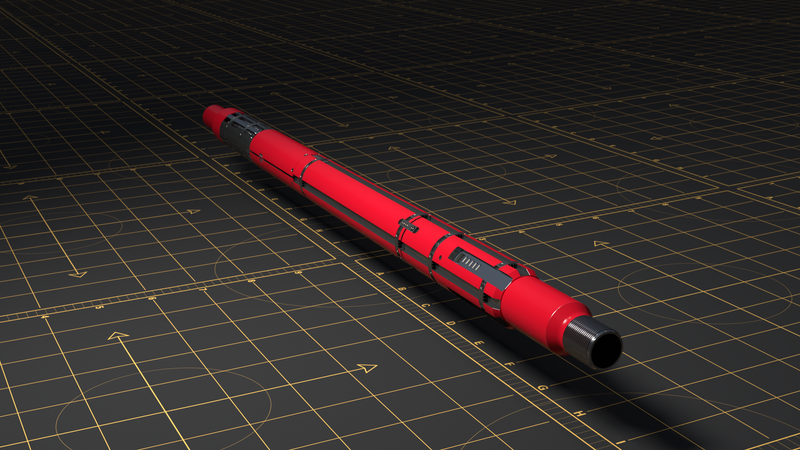

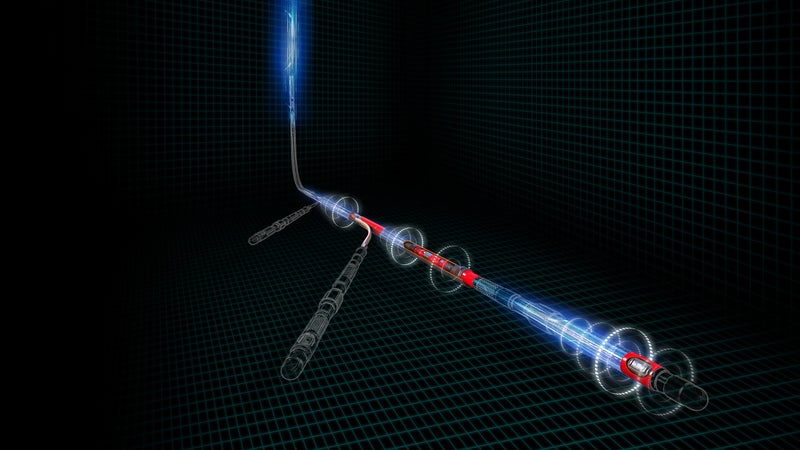

Talk to an expertFrom the leading provider of intelligent completion technology, the HS interval control valve (HS-ICV) enables deployment of Halliburton SmartWell® systems in more extreme environments. The HS-ICV is debris-tolerant and designed for high-pressure, deepwater environments.

The HS-ICV’s eight-position standard gas/liquid flow trims have been characterized to provide optimum production/injection at various positions. Optional onboard sensors track the movement of the flow trim. These position sensors provide the operator with real-time feedback to confirm valve movements.

Hydraulically actuated, the HS-ICV is operated remotely from surface using Halliburton’s direct hydraulics or Digital Hydraulics™ downhole control systems. The premium thermoplastic hydraulic chamber seals are designed to operate under high actuation pressures and temperatures ranging from 40ºF (4ºC) to 330ºF (165ºC). The valve has been subjected to a stringent qualification program, including temperature, pressure, debris, and erosion tests.

The body of the HS-ICV has slots to accommodate two ¼-in. dedicated instrument wires for position sensors. It also allows bypass of up to six ¼-in. bare hydraulic control lines or wires, all without compromising the valve body rating or working envelope.

Next-generation electro-hydraulic control system delivers fast, precise, bidirectional choke control and manages up to 12 ICVs using only three control lines

The direct hydraulics downhole control system uses direct hydraulic control lines from the surface to remotely actuate downhole flow control devices

The SmartPlex® II downhole control system is an electro-hydraulic multi-drop system that provides reliable zonal control of multiple valves in a single wellbore

The Accu-Pulse™ module enables incremental opening of a multi-position ICV to control produced or injected fluid rates for enhanced reservoir management

Halliburton intelligent completions technology help accelerate production and improve decision-making to increase ultimate recovery and maximize asset value