Search

Search

Search

Search

Next-generation electro-hydraulic control system delivers fast, precise, bidirectional control and manages up to 12 ICVs using only three control lines

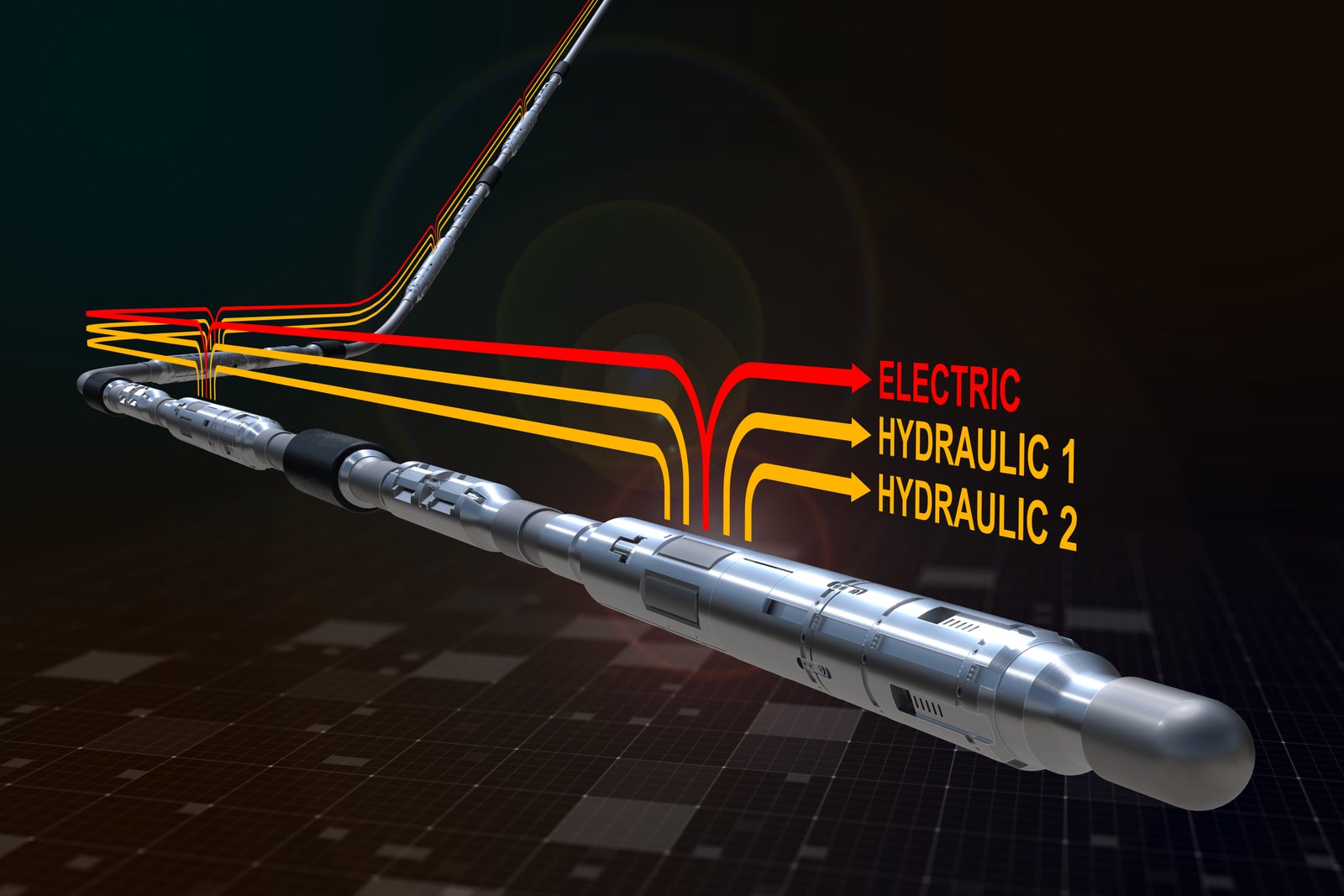

Talk to an expertTuring®, electro-hydraulic multidrop SmartWell® intelligent completion control systems deliver fast, reliable, bidirectional zonal control of up to 12 zones. It operates using only three control lines, two hydraulic and one single-wire tubing encapsulated conductor (TEC).

Operators can remotely and selectively adjust zonal ICV positioning in seconds. Built-in high–resolution sensors, increase fidelity and choke positions. Fast, precise bidirectional control of the ICVs enables flow control from or in each zone without closing the ICV. This capability supports routine and active well optimization, enables adoption of fully automated, data driven well optimization technology.

The single TEC line communicates with other downhole sensors such as DataSphere® gauges, without requiring additional wellhead penetrations.

Electro-hydraulic control and monitoring system

01:18

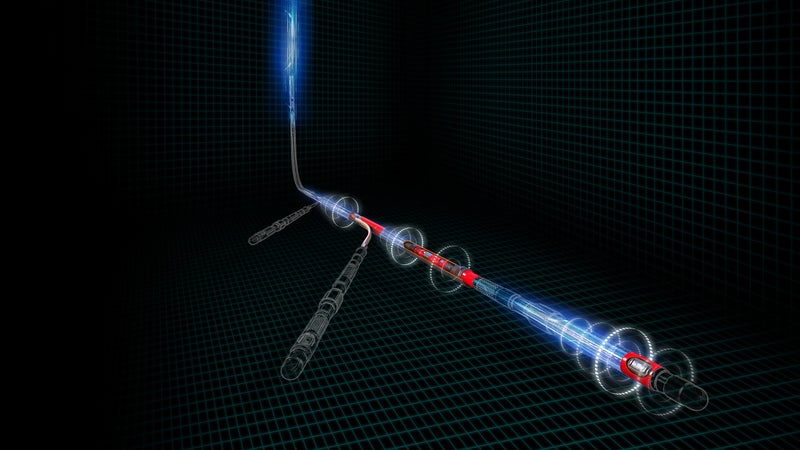

This is the first electro-hydraulic system capable of bringing 12-zone completions using three lines in subsea applications. It is suitable for any SmartWell® intelligent completion installation, including subsea, dry tree, extended reach, multi-lateral, water/gas injection, and CCUS.

This system helps improve reliablility and reduce OPEX and CAPEX, by simplifying installation, logistics and design.

The Turing® electro-hydraulic control system includes built-in health diagnostics. This provides operators with insights to potential issues before they occur.

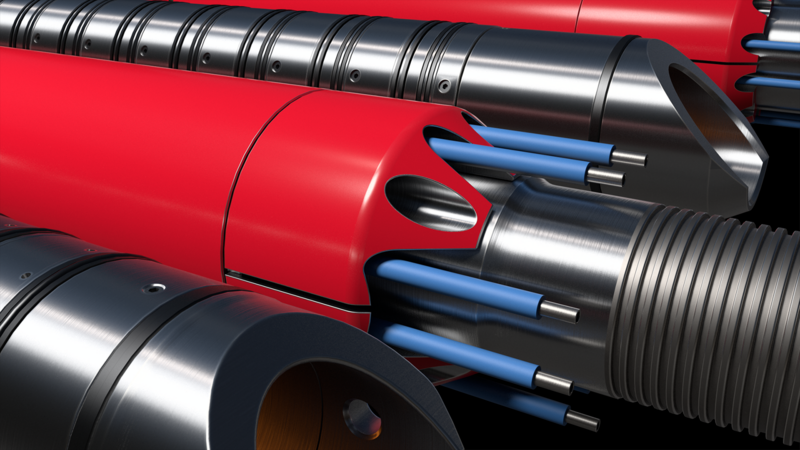

The Turing® electro-hydraulic control system uses an active electrical-switch design.

Each valve pairs with an actuator module, which allows selective remote control of each valve. Hydraulic lines supply the motive power to adjust the ICV choke position.

Three control lines—one electrical and two hydraulic—run from the surface and connect to each Turing system module.

The Fuzion® suite of wet-mate connectors facilitates removal of the upper completion from the lower completion without using destructive intervention methods.

The DataSphere permanent monitoring suite is a robust combination of the best in sand control, multilateral, and intelligent completion technology

Halliburton intelligent completions technology help accelerate production and improve decision-making to increase ultimate recovery and maximize asset value