Search

Search

Search

Search

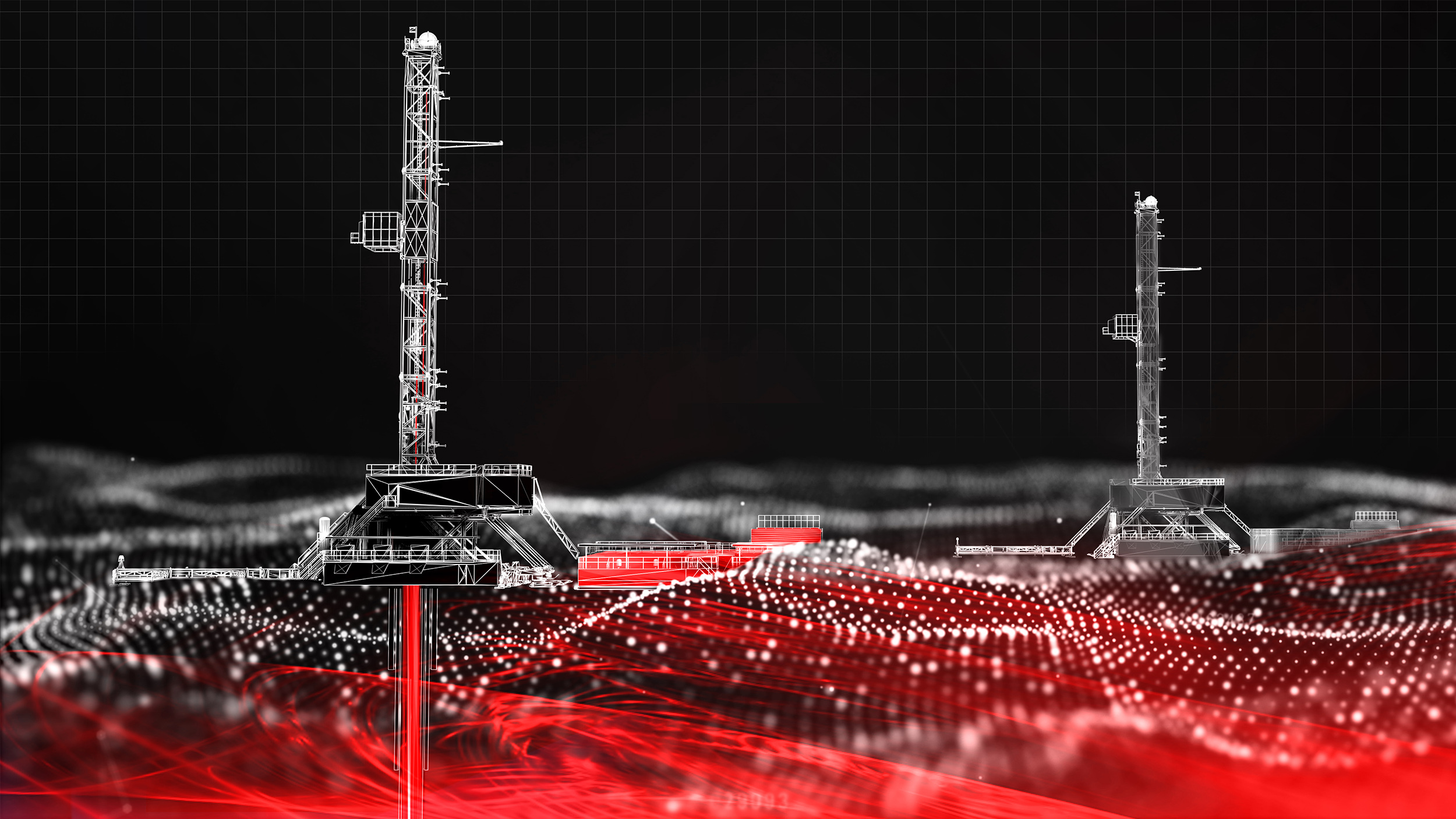

Halliburton delivers superior drilling performance to reduce time to first oil, enhance reservoir knowledge, and maximize production.

talk to an expertFor optimal drilling, we identify active vibration mechanisms, monitor hydraulics and refine expected conditions.

To ensure drilling integrity, Halliburton ADT® optimization specialists focus on preventing mechanical overload, fatigue, and excessive shock and vibration. We optimize annual pressures, hole clean up cycles, circulating system pressures, tripping time, and ROP within mud weight windows to manage hydraulics. We further protect wellbore integrity by defining pressure limits and identifying the optimum mud weight window.

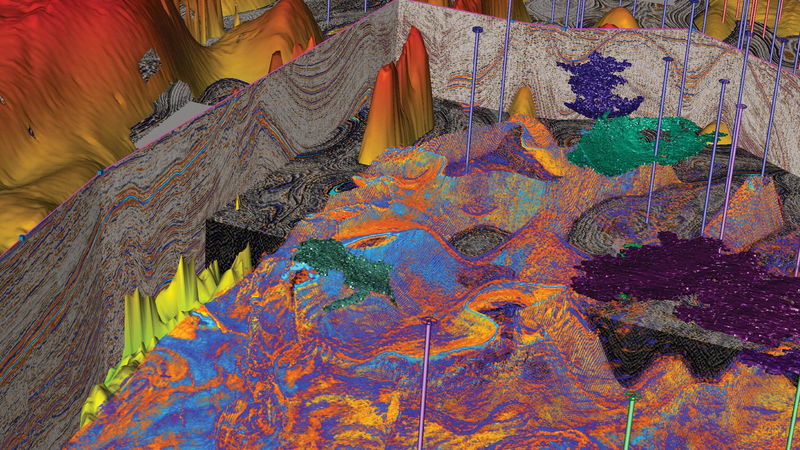

Well placement solutions that reduce positional uncertainty and minimize collision risk.

Explore

Using advanced real-time software to increase survey accuracy and reduce positional uncertainty.

Explore

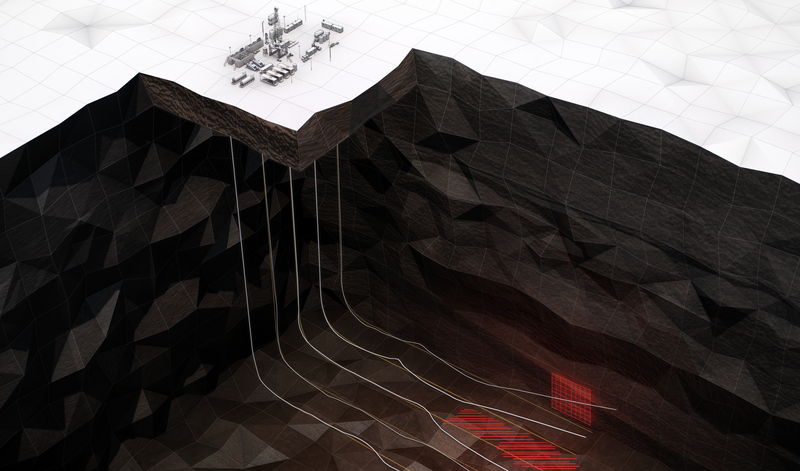

Maximizing performance with BHA and drillstring design, and real-time drilling optimization.

Explore

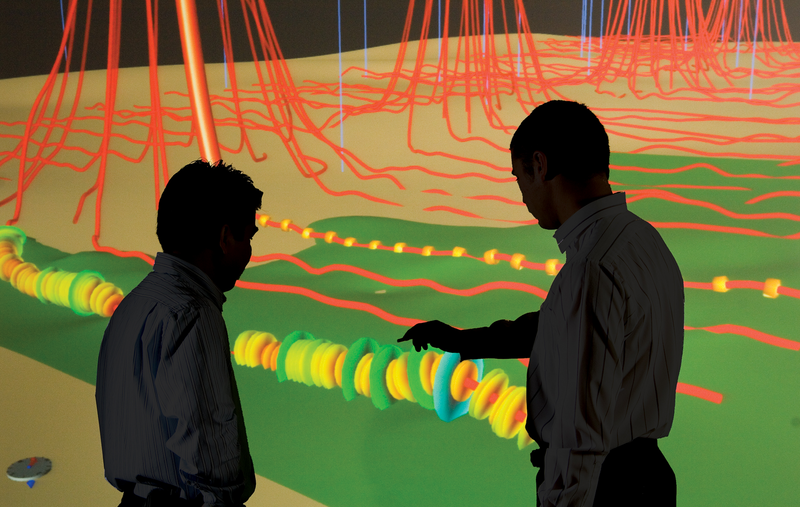

Halliburton uses advanced analytics and benchmarking to identify performance limitations and mitigate operational hazards.

Explore