Search

Search

Search

Search

Tailored slurry with ChannelFix™additive helps ensure zonal isolation without undesired fluid communication, despite potential mud channels

Download PDFHP/HT

Complex drilling conditions in HP/HT onshore field

Mexico

Within the current drilling environment of new, high-pressure/high-temperature (HP/HT), onshore fields in production in southern Mexico, operators face complex drilling conditions. They often must identify a reasonable compromise between maintained hole stability, safely running casing to bottom, and a cement operation that delivers zonal isolation with tight annular clearances.

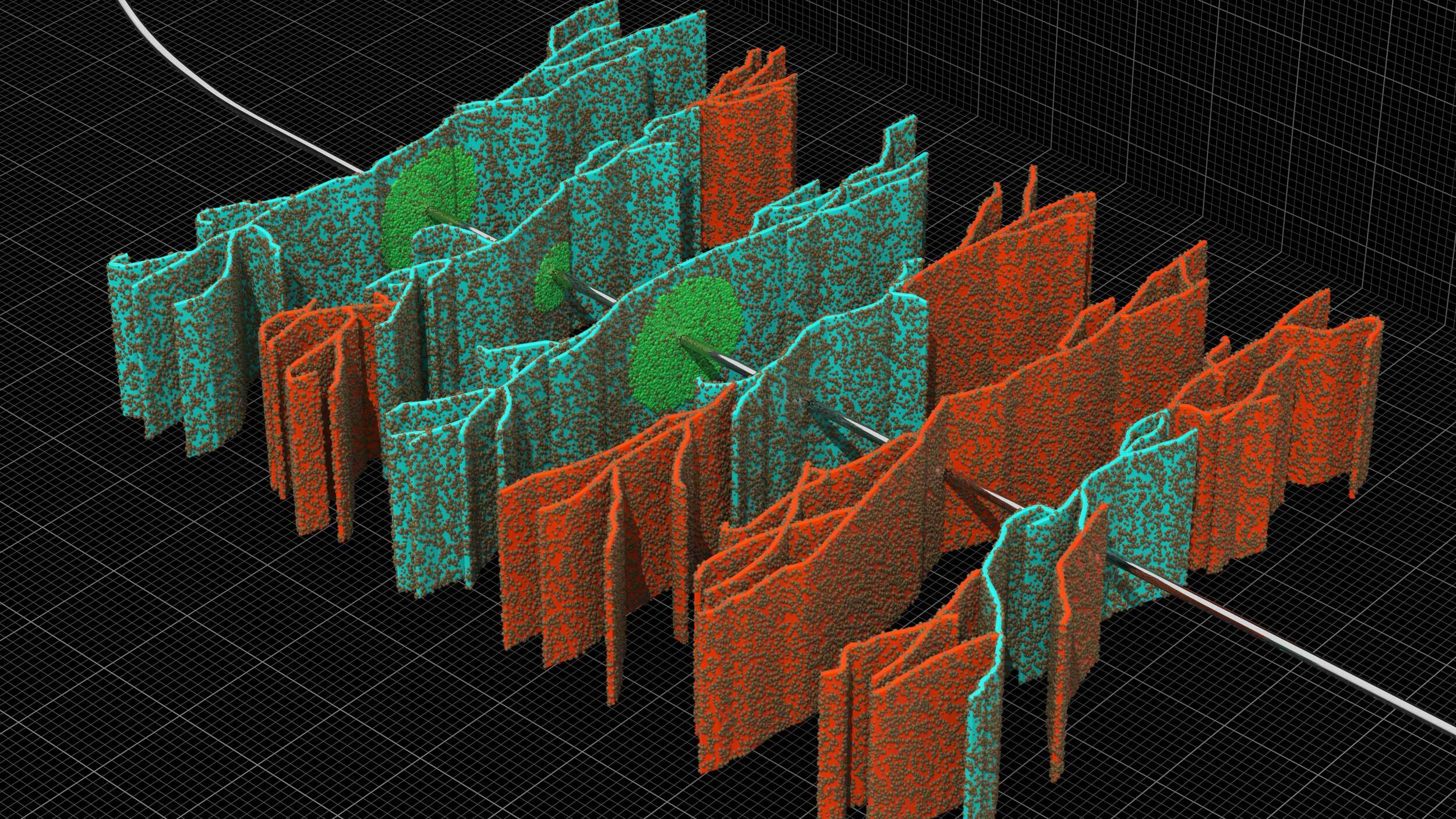

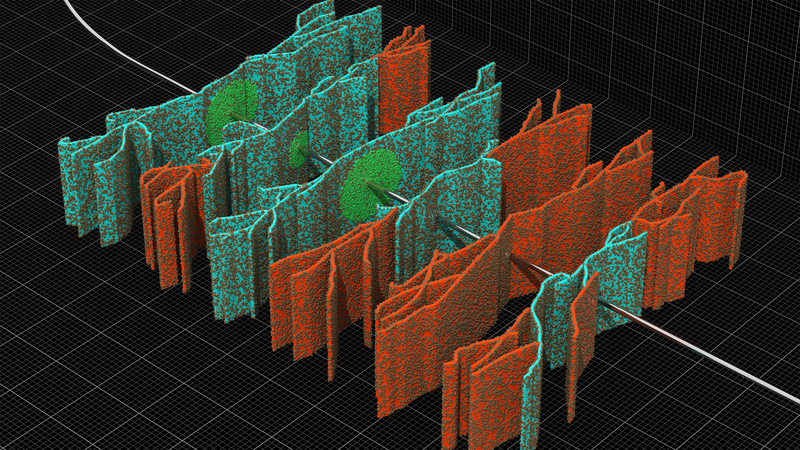

While pursuing successful casing runs, for which casing rotation is often required, the rigid centralizers necessary to withstand these forces provide a degree of standoff that is less than optimal. This increases the probability of immobile mud channels generated during the primary cement operation. Low annular clearances increase equivalent circulating density (ECD) during job placement, which often requires displacement rates that are not optimal for mud removal but necessary to ensure cement coverage to the desired top of cement (TOC). Deviated holes that near 30° inclination further increase the potential for channeling on the lower side of the hole.

Halliburton proposed the introduction of ChannelFix™ additive to a tailored cement design, with the goal to offset potential paths for undesired production generated by any remaining mud channel. ChannelFix additive exhibits controlled swelling in the presence of hydrocarbon, which provides a barrier for undesired zonal communication by reacting with residual non-aqueous fluid (NAF) to build a hydraulic seal and effectively remove potential annular flow paths.

Wells completed

Remedial work required

The cement operation was completed as per plan with the ChannelFix additive incorporated in the cement slurry. The isolation was successfully validated with pressure tests and the operator was pleased with the delivery of the barrier. If a residual NAF channel occurs, it will be properly sealed off by the controlled swelling reaction to maintain an effective seal, without the requirement for costly remedial work. A total of six wells were completed using this process with no remedial work required.

Swelling solution designed for barrier dependability and helps provide increased cement sheath elasticity.