Search

Search

Search

Search

Successful deployment in HP/HT gas well with loss rate of 1,000 bbl/hr

Download PDFMature fields

High loss rate in HP/HT gas well

China

An operator planned completion operations in both the upper and lower sections of a high-pressure/high-temperature (HP/HT) gas well. For the lower completion, a packer with a barrier valve and perforated pipe was to be run in the 6-in. openhole. After the lower completion and wellbore cleanup operations were complete, the upper completion system would be installed and the barrier valve opened via high pressure. During the drilling phase, high fluid loss up to 1,000 bbl/hr was observed before the completion operation was initiated. In consideration of future production needs, the operator decided to proceed with the lower completion procedures despite the high fluid-loss rate.

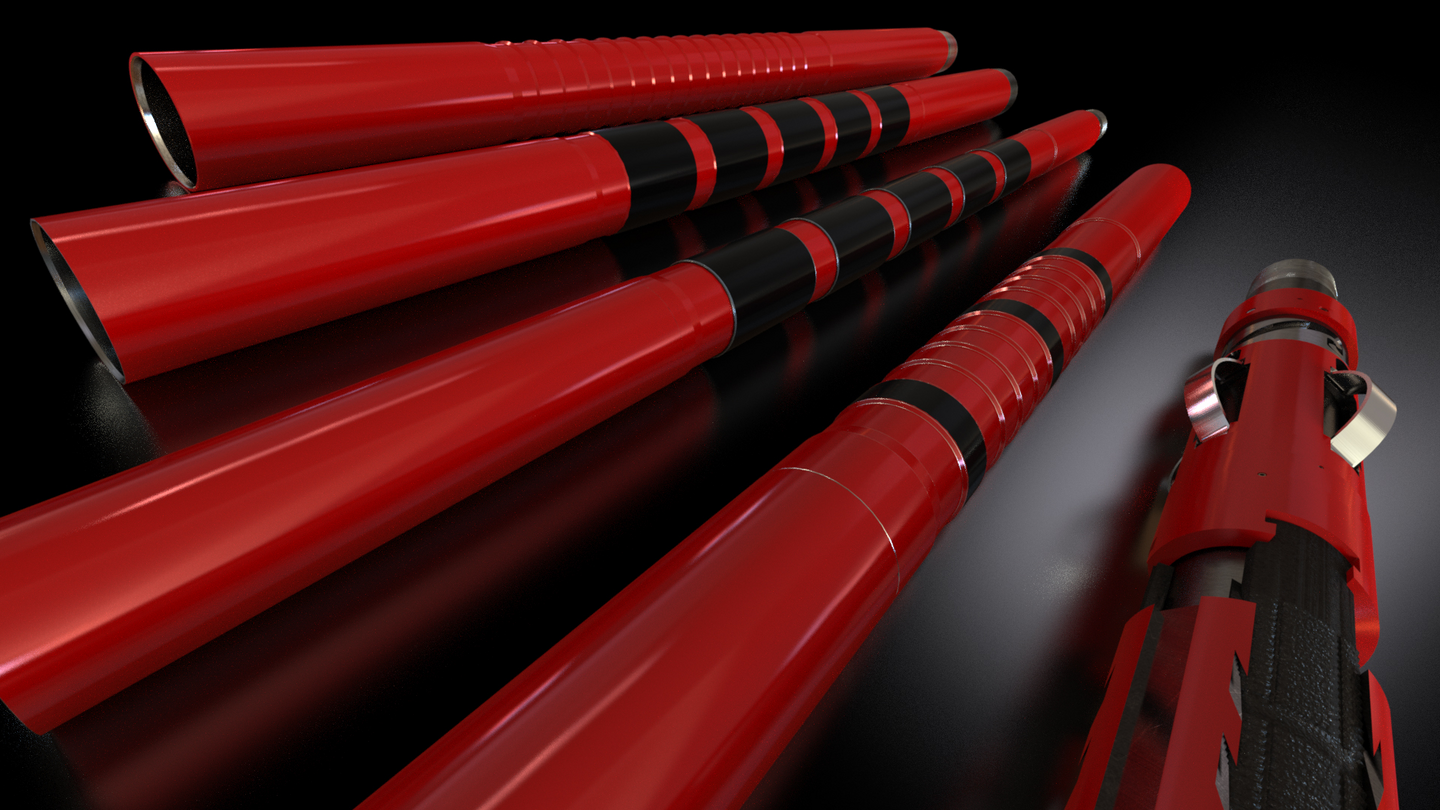

The operator collaborated with Halliburton to determine the best solution. It was decided to replace the top packer with an XtremeGrip® expandable liner hanger (ELH). The hanger was run with the barrier valve and perforated pipes to the target depth and then set against the barrier valve; the running tool was then released followed by a wellbore cleanout. Afterward, the upper completion tools were run and the barrier valve opened to initiate well production.

The completion operation was executed smoothly, despite the loss rate, which remained steady at 1,000 bbl/hr during tripping-in. The string was deployed to the target depth, the ELH was set, and the running tool was successfully released. Subsequently, the operator and Halliburton completed a wellbore integrity test and performed wellbore cleanout circulation.

The barrier valve was opened at 7,600 psi after the upper completion operation, and the hanger remained intact. The well began successful production. The operator now plans to use this solution for similar situations in this field.

A packer would be unable to withstand pressure at a loss rate of 1,000 bbl/hr, and element destruction during tripping in could result. In addition, if the string becomes stuck in an HP/HT gas well, there is a significant risk of gas escape from the formation attributed to mud loss. Conventional liner hangers, with their larger outer diameter (OD), can create higher equivalent circulating density (ECD), which is less safe compared to an ELH. The barrier valve also requires high opening pressure, which poses an additional challenge to conventional hangers.

Halliburton collaborated with the operator to develop a reliable solution. This included torque and drag simulations tailored to the current situation with an engineer on standby for real-time support. Simultaneously, the local Halliburton team worked with the global product team to refine the solution and ensure the best possible outcome for the operator. Effective communication with the operator and field crews regarding rig operational details was crucial.

To meet the rig schedule, Halliburton promptly assembled and mobilized a 5×7-in. XtremeGrip ELH assembly with running tools for immediate deployment.

Gas well in upper and lower sections

bbl/hr lost rate

Inch ELH a robust solution

Issues related to HSE, SQ, or NPT

During the operation, the 5×7-in. ELH proved to be a robust solution, which offered high tensile strength, high torque capacity, and the capability to withstand high circulation rates and pressure limitations. The XtremeGrip ELH system enabled the operator to set the liner hanger and top packer against the barrier valve via full hydraulic activation immediately upon reach of the target depth (without the need to drop a ball).

Implementation of the ELH solution effectively addressed the high fluid loss and prevented costly remedial operations, such as fishing and pipe recovery. Installation was successful with zero NPT or HSE/SQ issues.