Search

Search

Search

Search

Combined magnetic ranging services for precise alignment of sidetrack and target well

Download PDFMature fields

Reenter a leaking geothermal well to complete a complex P&A operation

Paris, France

Engineered drilling solution, using the following combination of magnetic ranging services:

An operator with a leaking geothermal well in inner-city Paris, France, was fi nding it diffi cult to mill a drillpipe cemented up to approximately 2,782 feet (848 meters) of measured depth (MD) on a complex plug and abandonment (P&A) operation. This well had been completed decades ago and was severely corroded, leaving very few remnants of magnetic signatures, rendering passive magnetic ranging (PMR) insuffi cient on its own.

Sperry Drilling was selected to accurately steer a sidetrack well, providing precise measurement of distance and direction to the casing of the target well. A specialized Proximity Ranging and Interception team had the expertise for this job, having worked on all types of well interception scenarios. The implementation of not one, but two magnetic ranging systems, both passive and active, delivered greater survey accuracy than conventional techniques. This enabled the operator to overcome previous challenges and effi ciently achieve its goal in less than three weeks – leading to successful milling into the geothermal well, while also saving more than USD 200,000 in rig time and ranging run costs.

Essentially, the operator could not complete the P&A project because the drillpipe was stuck above the formation zones that needed to be isolated. To properly P&A the well for zonal isolation, cement plugs had to be set below the fi sh. Multiple attempts were made to fi rst fi sh out the drillpipe and then mill through it, but these efforts were unsuccessful. After several frustrating, costly months, it was concluded that the most viable option was to sidetrack around the drillpipe, enabling interception and reentry into the original wellbore for setting the cement plugs.

Sperry Drilling collaborated with the operator to fully understand its unique challenges and requirements, leading to a combined recommendation of the WellSpot™ intercept magnetic ranging service and the Passive Magnetic Ranging (PMR™) service for ranging between the sidetrack well and the target well. Because active access-independent magnetic ranging techniques do not require deployment of a system into the existing wellbore, it was the right choice for addressing the damaged casing and cemented drillpipe on this project.

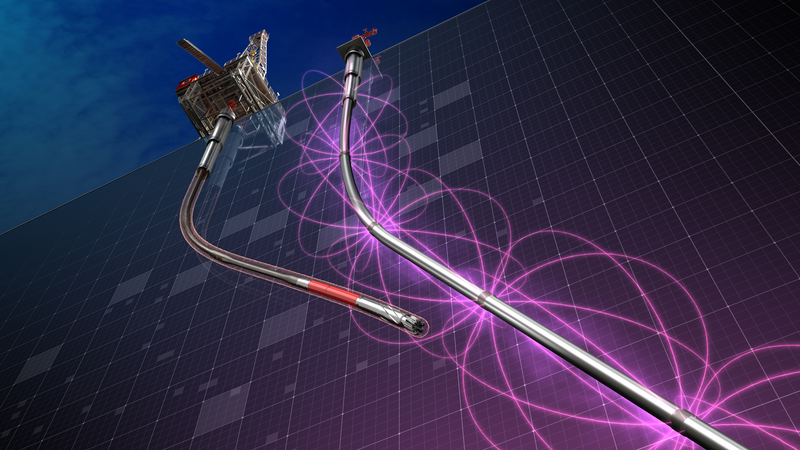

Ranging activities began at around 2,800 feet (853 meters) MD, approximately 250 feet (76 meters) after the sidetrack, to confirm the sidetrack drilling results and reduce the positional uncertainty between the two wellbores. Ranging operations continued to be performed periodically to maintain optimal proximity for the interception and milling. At approximately 3,500 feet (1,067 meters) MD, edge-to-edge contact was made with the target well casing at an ideal alignment and incidence angle for milling and reentry.

The WellSpot service helped to minimize positional uncertainty between the two wellbores by maintaining measurement of distance and direction to the target well. It also ensured that the operator would obtain the optimal alignment for milling and reentry through its ability to accurately provide distance and direction to the target casing.

Typically, passive ranging uses the already present magnetic remnant field on the target well casing to calculate a distance and direction to that target well casing. Although it was not the ideal solution to determine the distance and direction in this case, due to the corroded casing, it was used throughout the well to monitor magnetics and extend drilling intervals between ranging runs. The ability to extend drilling intervals and perform fewer active ranging runs saved the operator time and money

feet depth of the cemented drillpipe

USD in cost savings

time to complete the operation

This innovative solution – in particular, the high accuracy of the WellSpot service – precisely guided the trajectory of the sidetrack well, completing the operation in a single wellbore. The combined services made it possible for the operator to perform at least two fewer runs than estimated to complete the interception, thus saving approximately USD 60,000 per run, along with rig-time costs – in totality, valued at more than USD 200,000. With a highly accurate alignment of the trajectory of the drilling well to the target casing, the operator was able to successfully mill a window for reentry into the target casing for P&A. These services enabled the operator to finally complete the P&A process on this geothermal well – in a safe and environmentally compliant manner – after months of previous attempts, and maximize the value of the geothermal asset.

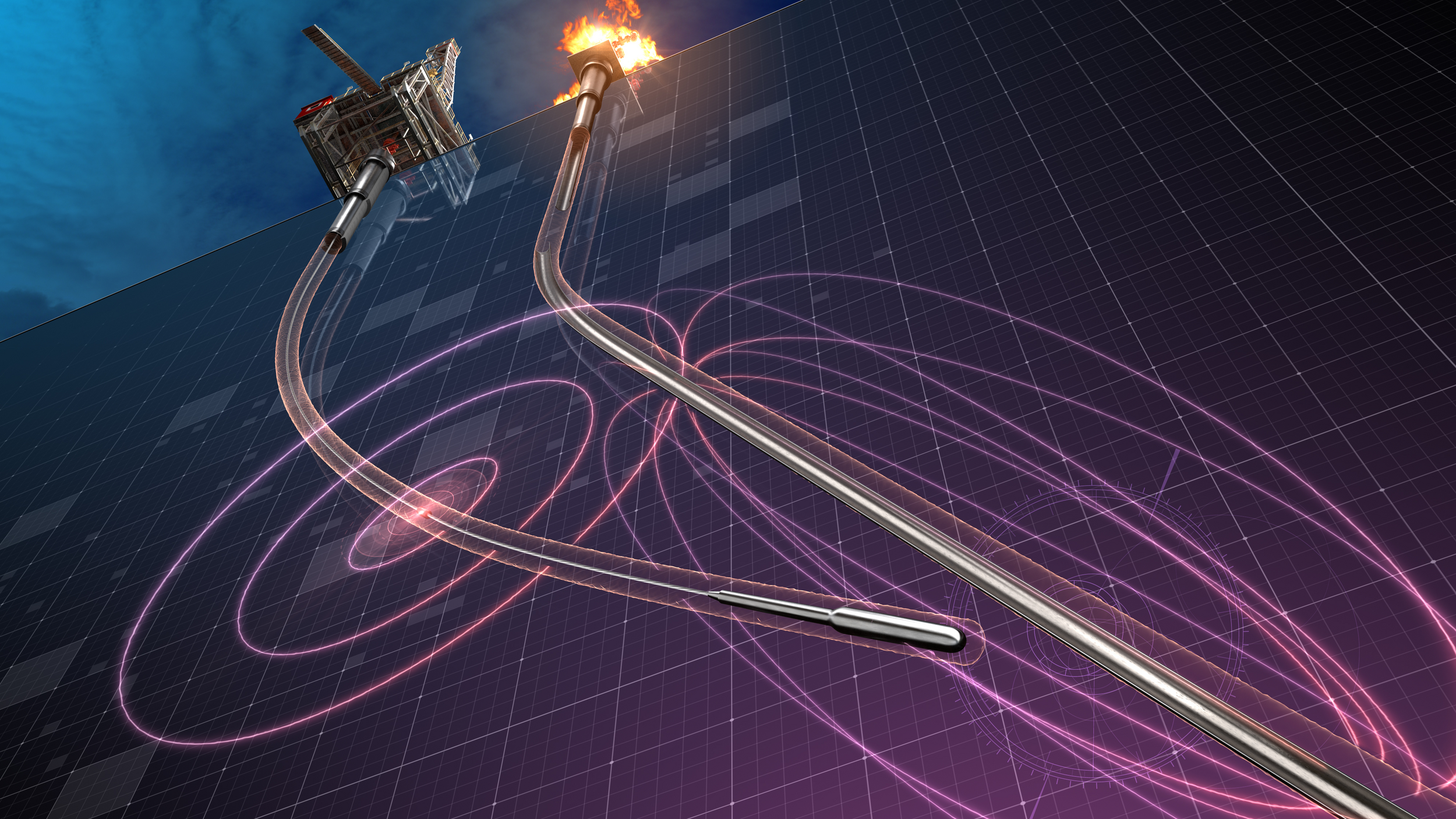

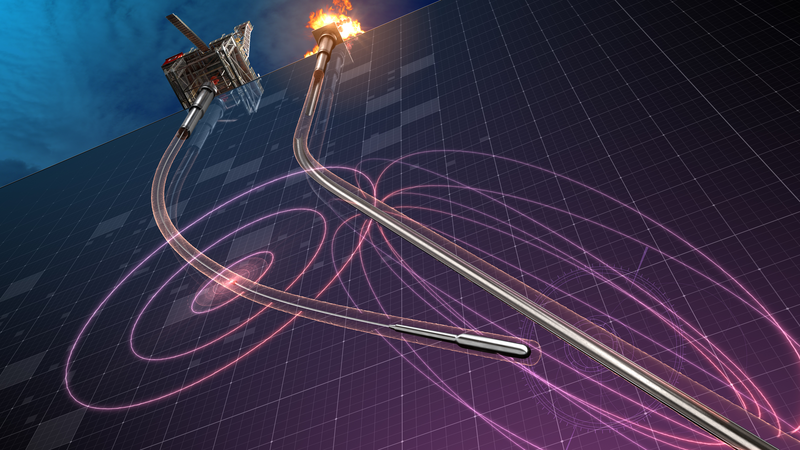

WellSpot™ active magnetic-ranging systems use precise sensors to provide data for multiple drilling applications.

The Passive Magnetic Ranging (PMR) service utilizes the remnant magnetic fields on target well tubulars to provide a distance and direction between wellbores.

Magnetic ranging solutions demonstrate a well-established history of expertise, proving our dedication to precision when navigating the intricacies of well proximity applications.