Search

Search

Search

Search

Geothermal projects require the utmost efficiency to help ensure a return on investment

In the 1990s, geothermal operators discovered the benefits of electric submersible pumps (ESPs), an artificial lift technology, for geothermal water extraction. These pumps, tried and proven in the oilfield to maximize hydrocarbon extraction, drew upon established techniques to remove subsurface fluids, which made them attractive to smaller-scale operations such as local heating networks and wellness baths. As geothermal operators pushed the limits of traditional applications and began exploring deeper depths, ESP use expanded to handle more significant outputs of up to 150 liters per second and withstand temperatures of 150°C.

However, traditional ESPs hit their limits in geothermal applications. Extreme temperatures, corrosive brines, and strenuous operating conditions pose challenges and require operators to seek hardier solutions. The fluid extracted from geothermal wells lacks oil, which affects lubrication. Limestone-derived calcium carbonates could also cause scaling in essential pump and seal areas. While traditional high-flow ESP pumps perform well in standard water lifting, they risk potential failure under these intense geothermal conditions. In seasonal temperature changes, motor bearings and power connectors may experience even more stress that could cause failure.

The risks of bolted bowl-type pumps highlight requirement for tailored solutions

The geothermal industry originally adapted bolted bowl-type pumps, which originated from shallow cold water lifting applications. However, their limitations and safety concerns meant the industry required a new solution to withstand the demands of deep-set geothermal applications. Otherwise, operators could experience equipment failures due to the pressure, temperature, and vibrations inherent in geothermal wells.

A notable incident with a European customer highlighted the risks inherent in bolted bowl-type pumps. When a pump failed on site, the operator lost equipment downhole. Upon further inspection, the operator discovered vibrations due to the pressure in the well dislodging the downhole-facing bolts and cracking the bowls due to metal fatigue. This underscored the dangers of using pumps not designed for the conditions of deep geothermal wells.

Traditional intake design requires up to 50 kW more power to lift and meet high geothermal flow demands. However, a reduction of 2-bars at a flow rate of 400 m3/h (111 L/s) necessitates 45 kW less lifting power applied at the surface.

Calculated at €0.30 per kWh over a year, this equates to about €128,000 saved per year.

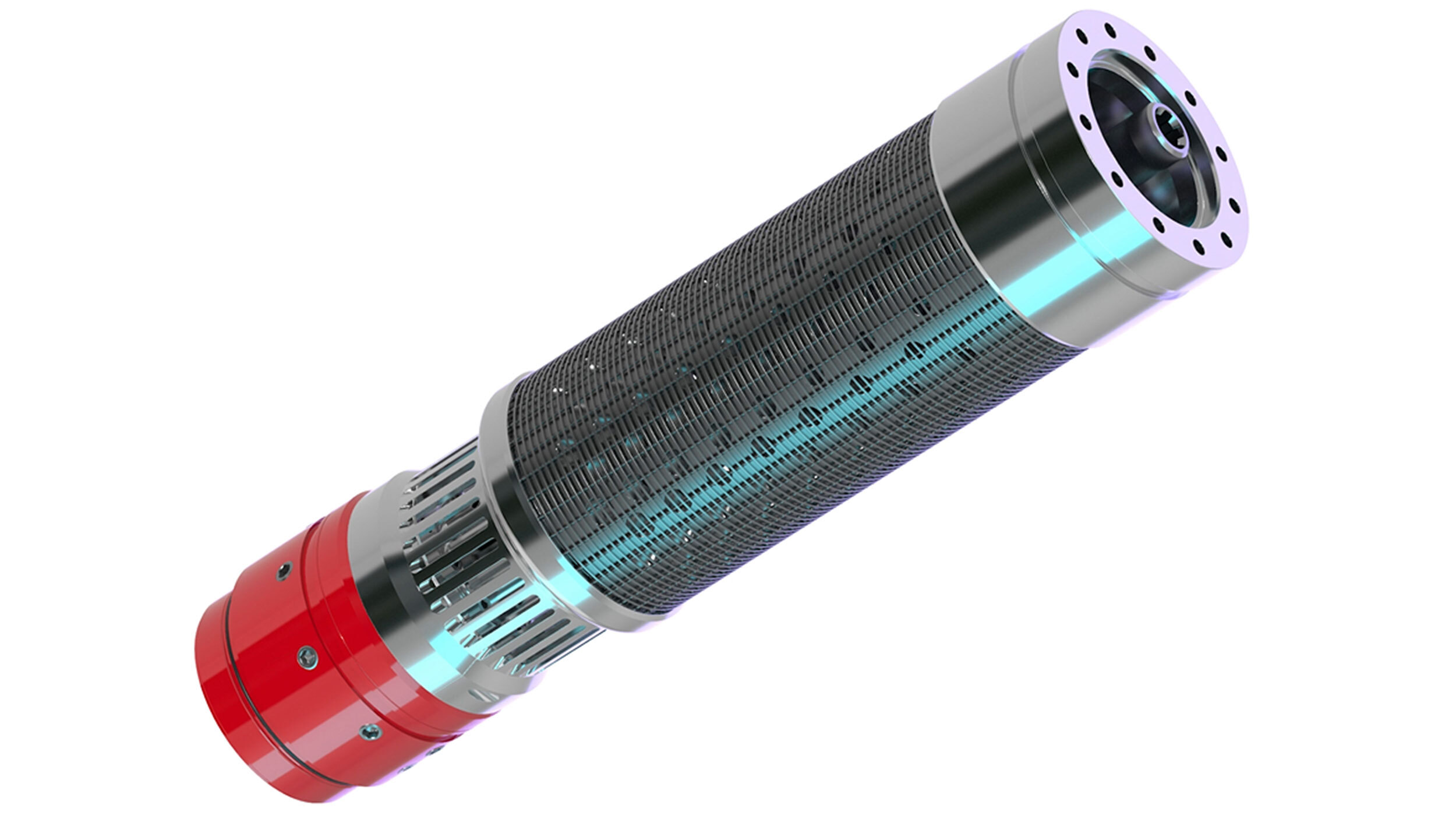

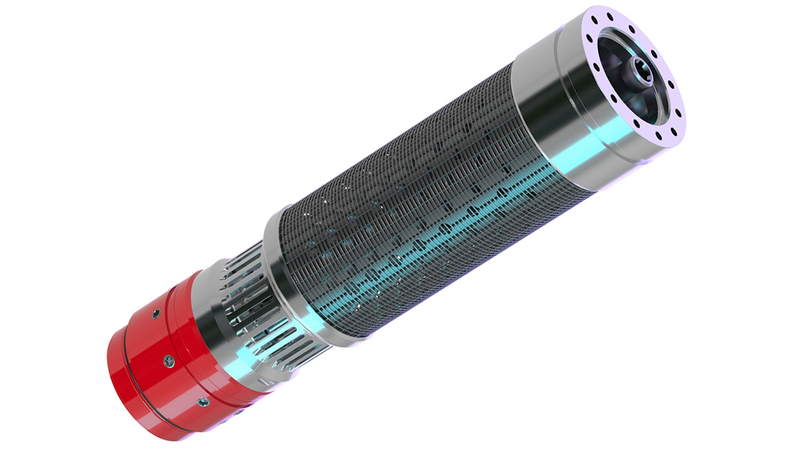

Innovative, modular design seamlessly adapts to a diverse array of pumps and seals, delivering unparalleled solids protection in geothermal applications.

Simple, plug-and-play surface solution that feeds into our geothermal downhole pump when conducting well inflow performance tests.

Tiger Shark® electric submersible pumps are designed to adapt to changing well production, improving operating range and run life in harsh environments.

Halliburton delivers a low cost per megawatt in geothermal well construction by driving efficiencies in asset development, from field exploration through field optimization.

Explore