Search

Search

Search

Search

Successful offshore thru-tubing intervention perforating application

Download PDFMature Fields

Provide retrievable plugging assembly

Norway

An operator offshore Norway planned numerous perforating operations in a well above the intervention solution packer assembly post-installation, which introduced the risk of pressure waves. After a review of competitor offerings, the operator asked Halliburton to deliver a solution to improve the production flow area in the well within a short timeframe to meet the operational schedule.

The operator wanted a better production flow area than offered by competitor products and provided Halliburton software-generated shock wave estimates for consideration. The operational schedule had a short turnaround, so off-the-shelf product availability was crucial.

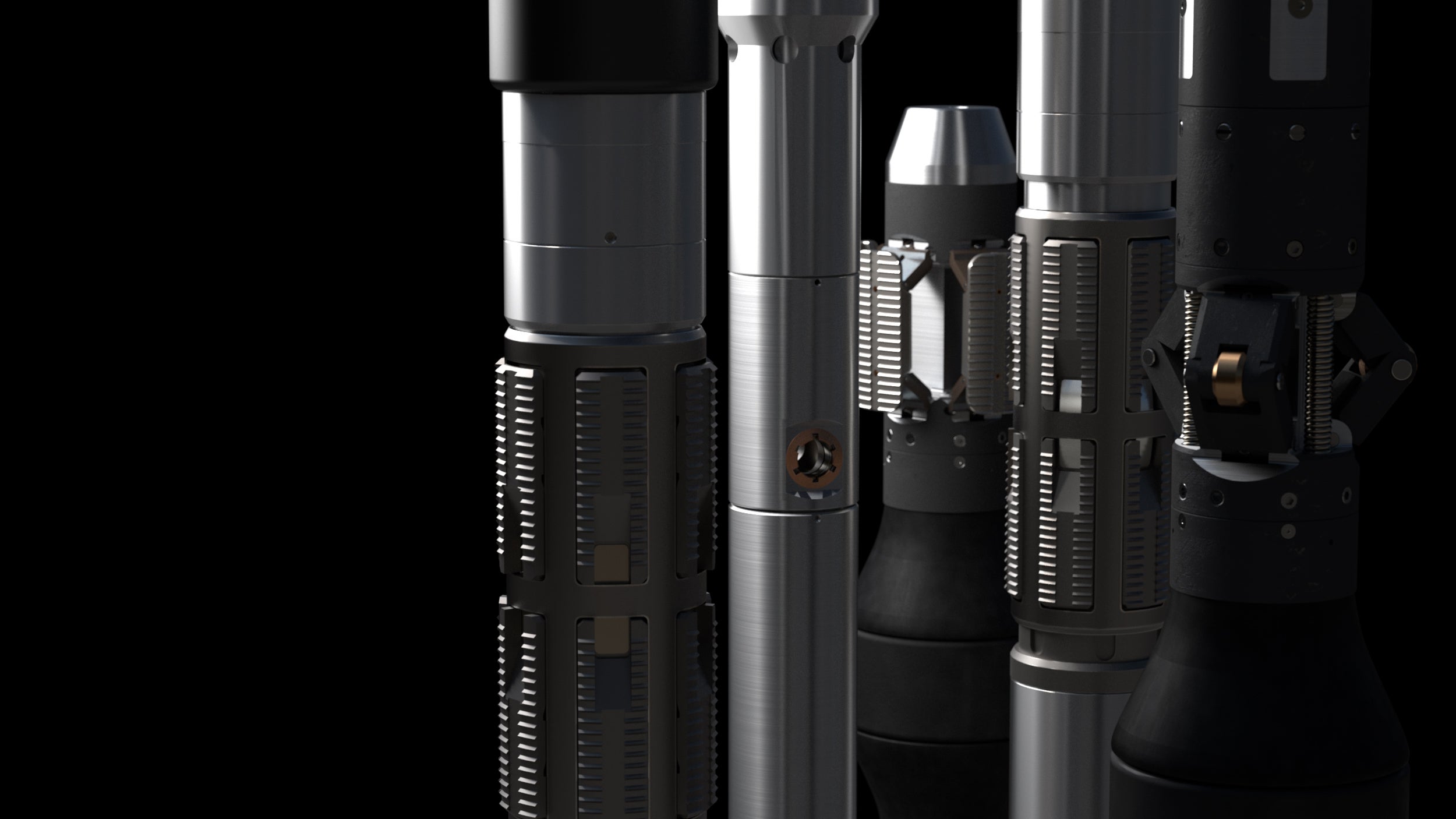

After a technical review of the shock wave estimates and other data, Halliburton recommended a 5 1/2-in. B-type intervention solutions packer assembly with an equalizing sub and fluid-loss valve. The assembly was within specified limits, and the increased assembly ID improved the production flow area compared to the competitor offerings. The equalizing sub was not equipped with shear pins, but was pressure balanced with O-rings above and below. The fluid-loss valve prevented potential cross-flow from lower penetrations into the new upper perforations. In addition, the integrated operations with equipment installation completed by the operator’s personnel would help reduce overall personnel costs.

in. B-type packer assembly increased flow area

Successful perforating operations before bad weather

More completed thereafter

Perforating operations were successful. The packer assembly improved production throughout the larger ID. Three initial perforating operations were completed before inclement weather was encountered. An additional six perforating operations were completed thereafter.

The operator lost guns during the last perforation run. This was not of great concern because the 100 m above the packer was highly deviated and did not allow the guns to free fall. This issue was anticipated during the risk review, where it was established that because the bullnose on the guns fits well on top of the packer, lost guns would likely rest on the packer assembly and could be recovered via a fishing operation. The guns were fished out of the hole and rerun; the well is now on production.

Customizable intervention solutions for wellbore remediation reduce well time and costs.