Search

Search

Search

Search

SuperFill™ surge reduction system unlocks significant achievement in liner RIH speed and induced fluid-loss reduction

Download PDFMature Fields

Reduce well construction timeline and minimize mud loss to the formation

Offshore Mexico

A major operator in Mexico faced recurrent well-construction difficulties in a development field, including excessive run-in-hole (RIH) time and costly mud losses during liner deployment. These issues were compounded by slim-hole designs and narrow operational windows between pore pressure and fracture gradient, which limited trip-in speed and increased risk.

To address these constraints, Halliburton deployed the SuperFill™ II diverter tool across eight wells. The tool’s design enabled faster casing runs while minimizing surge pressure and fluid loss. The operator achieved an average 135% increase in trip-in speed and reduced mud loss by 34%.

The operator’s offshore wells featured tight annular clearances and limited pressure margins, which increased the complexity of running casing and liner strings. These conditions often required slower trip-in speeds to avoid formation damage and fluid losses, which extended the well construction timeline and increased costs.

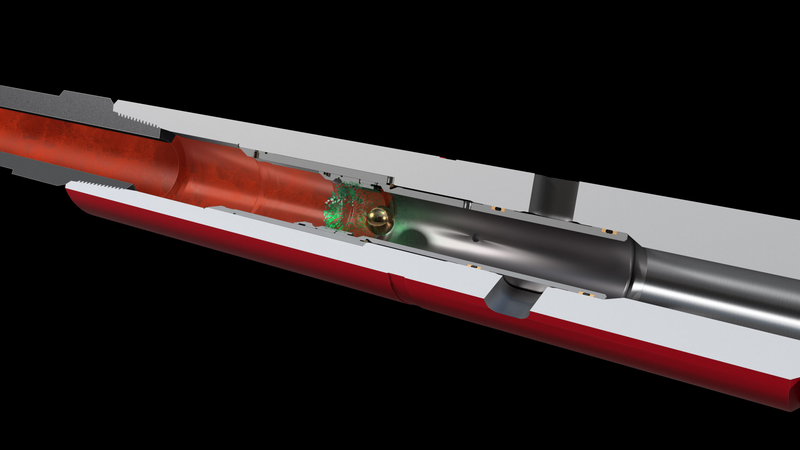

Halliburton introduced the SuperFill™ II diverter tool in four rigs operating in an offshore field in Mexico. The tool features large side ports and an open bypass area that diverts auto-fill fluid from inside the landing string to the annulus, just above the casing or liner hanger. This design reduces surge pressure and re-establishes conventional wellbore flow patterns, which improves surface fluid management and safety.

The diverter’s minimal moving parts and glass ball seat ensure reliable closure. Once nominal pressure is reached, the seat shatters to allow unrestricted internal flow, maintaining operational integrity.

Average trip-in speed increase

Reduction in mud loss

psi average closing pressure

Using in-house surge and swab simulations, Halliburton optimized trip-in speeds for each well. The SuperFill™ II diverter was deployed successfully in all eight wells, delivering consistent performance and measurable improvements. Trip-in speed increased by 33, 80, 153, and over 300% across the four rigs. Mud loss was reduced by 34% compared to similar operations without the diverter.

These results helped the operator accelerate well construction, reduce fluid-related costs, and improve operational efficiency across the field.

Discover the SuperFill™ II diverter, a cutting-edge solution for auto-fill float equipment designed to reduce surge pressure and improve casing run efficiency.

The SuperFill™ family of float equipment is designed to help reduce the effect of surge pressure to optimize casing running speeds.