Search

Search

Search

Search

Tuned® Defense™ E cement spacer combined with IsoBond™cement system provides excellent CBL results

Download PDFUnconventionals

Prevent and cure seepage losses during cement operation

Argentina

The Vaca Muerta basin in Argentina ranks among the world’s largest unconventional reservoirs. To unlock the full potential of unconventional oil resources, hydraulic fracturing through cemented casing strings must achieve proper zonal isolation. This ensures effective stimulation and long-term well integrity.

An operator drilled in a new area of the basin and faced low fracture gradients and significant losses. Cement bond log (CBL) results in the 7 5/8-in. intermediate section of the first three wells were unsatisfactory. The operator required a reliable top of cement (TOC) to isolate the Quintuco formation and confirm integrity at the shoe before advancing to the production section. Although formation integrity tests (FIT) returned positive, poor cement bonding at the shoe raised concerns about long-term isolation and fluid migration

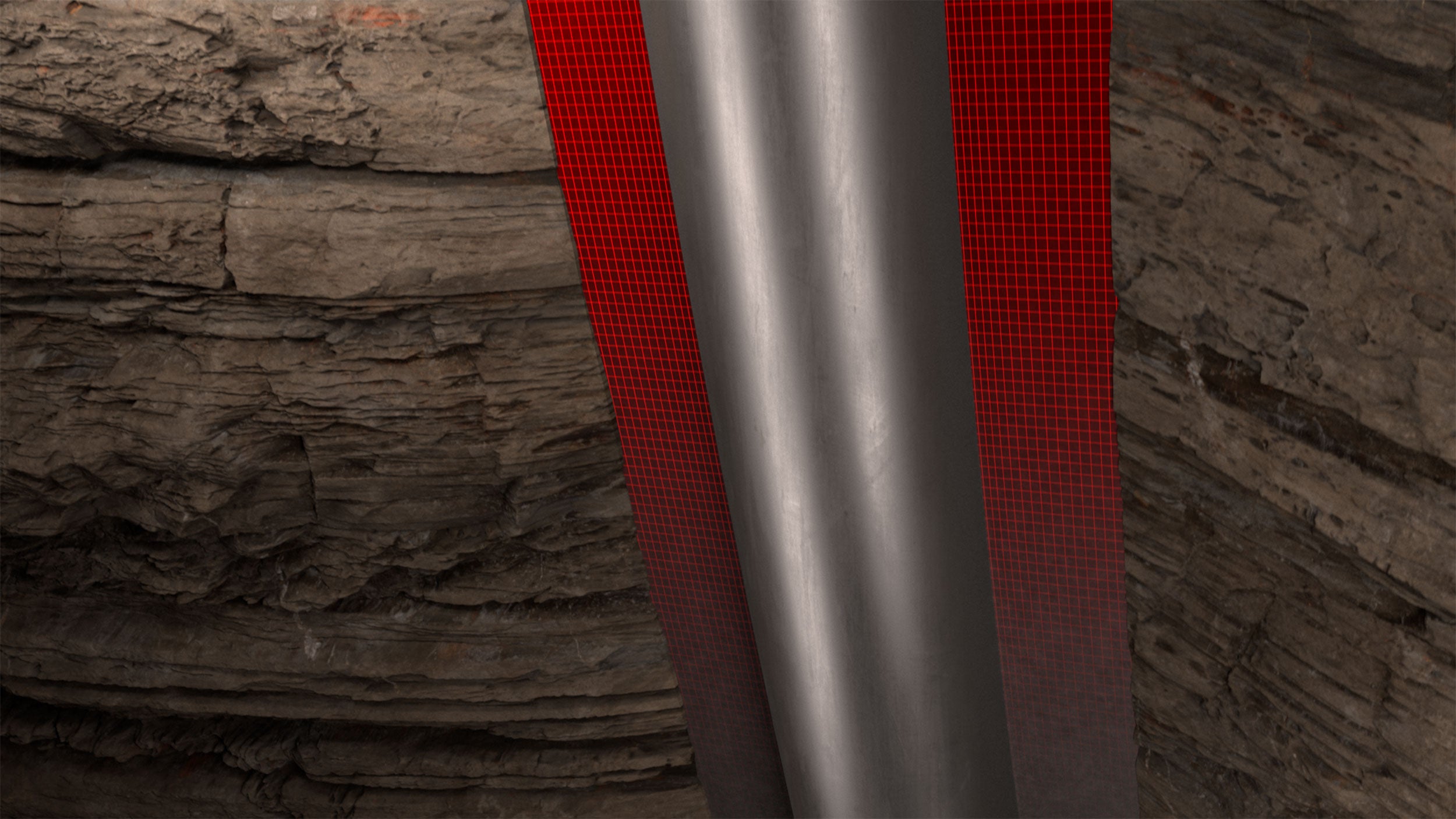

Halliburton recommended the IsoBond™ cement system, a tailored slurry that offers excellent fluid-loss control and a short transition time. IsoBond cement system builds rapid gel strength and reduces permeability, which helps improve anchoring and prevents debonding that could allow fluid or gas migration.

To further improve placement, Halliburton pumped Tuned® Defense™ E cement spacer ahead of the IsoBond system. This spacer displaces mud efficiently and helps control losses in permeable and fractured zones, especially in environmentally sensitive areas. It also helps reduce the need for remedial cementing and protects production zones.

Application Tuned Defense E cement spacer in Argentina

lbm/gal Tuned Defense E cement spacer pumped

Losses

Confirmed isolation

This operation was the first application of Tuned Defense E cement spacer in Argentina. The team pumped 60 bbl of 10.5-lbm/gal spacer ahead of a 12.5-lbm/gal lead slurry and a 15.6-lbm/gal tail slurry at 4 bbl/min. This approach optimized annular velocity without exceeding the fracture gradient. No losses occurred during the operation.

The operator achieved excellent CBL results and confirmed cement integrity at the shoe. This success allowed continued drilling into the production section and improved long-term zonal isolation.