Search

Search

Search

Search

Machine learning algorithms help operator obtain accurate fracture map to support strategic water disposal plans

Download PDFManaging rising water output amid disposal limits and complex fractures

Permian Basin

An operator in the Permian Basin faced a common challenge: increased water production and limited options for water disposal due to regulatory restrictions and complex underground fracture networks.

To address this, Halliburton deployed the StrataXaminer® imaging service with hybrid inversion processing to help the operator better understand subsurface fracture systems. With the assistance of AI and machine learning algorithms, the tool helped the analyst distinguish between open and closed fractures and provided a reliable, accurate fracture map.

The operator then could more accurately model fluid pathways, optimize water disposal strategies, and avoid further exacerbation of water production issues through the avoidance of sensitive zones. This approach provided a clearer picture of the subsurface, which enables smarter well placement, reduces the risk of unintended water injection, and improves operational efficiency in a mature and water-intensive field.

Many operators in the Permian Basin grapple with the region’s geological complexity and regulatory constraints. In particular, the average well now produces nearly four barrels of water for every barrel of oil extracted – an increase of over 350%. Natural fracture networks that allow water production into wells exacerbate the problem. This not only reduces oil output efficiency but also creates logistical and environmental burdens related to water disposal.

To compound the issue, state regulations restrict the use of deep saltwater disposal wells due to concerns over induced seismicity. As a result, operators inject produced water into shallower formations. This leads to a problematic cycle: water injected into these shallower zones often reappears in nearby wells due to open or reactivated fractures, which worsens the water cut.

The operator theorized that an accurate map and understanding of subsurface fracture networks would help it determine where water flowed and how to avoid the reactivation or creation of new fractures. Without this insight, it based water disposal decisions on trial and error, which increased the risk of unintended consequences such as water breakthrough in offset wells. Traditional methods of fracture identification require further information, such as core data or production data, for accuracy.

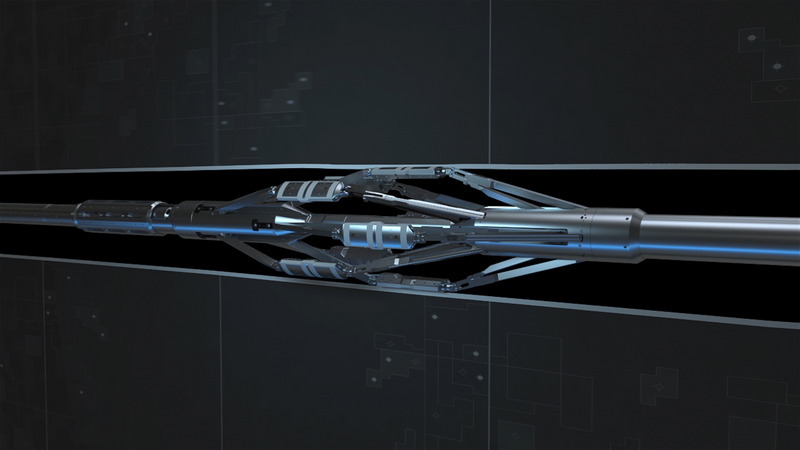

Halliburton deployed the StrataXaminer® high-resolution imaging in oil-based mud imaging service with hybrid inversion processing to gather subsurface data, map fracture networks, and characterize fractures. This advanced imaging technology allowed the operator to visualize and interpret the subsurface fracture network with greater accuracy than traditional methods, and in less time due to the hybrid inversion methodology.

The StrataXaminer service captured high-resolution standoff images of the borehole and revealed the presence and orientation of fractures. Machine learning algorithms that draw from a vast database of tool responses, such as responses to formation resistivity, mud, and standoff, developed initial estimates for flushed zone resistivity, permittivity, standoff, and electrical loss.

Inversion processing converted the raw sensor data into useful geological information. This helped engineers differentiate between fractures that would allow fluids to pass through and fractures that would not.

Pad tool for maximum coverage

Borehole coverage

Fractures reclassified

The StrataXaminer imaging service with hybrid inversion processing significantly improved the operator’s understanding and management of subsurface fracture networks. The operator reclassified 17% of their fractures after receiving the inverted images, a critical change when considering water injection in problematic zones.

This improved fracture characterization led to the development of more reliable field-wide fracture network models, which support smarter well placement and more strategic water disposal plans. The identification of optimal injection zones and avoidance of areas that could lead to water recycling or interference with nearby wells helps the operator mitigate the risk of water production exacerbation.

Additionally, the hybrid inversion methodology bolstered the accuracy and efficiency of data interpretation. The operator could reduce the guesswork that guided previous disposal decisions. This approach not only upgraded operational decision-making but also laid the groundwork for long-term improvements in water management strategy across the field.

Reservoir Xaminer™ grants high-quality formation evaluation data in real-time for improved data quality, optimized rig time, and a higher asset value.

StrataXaminer™ provides more accurate well data to better evaluate production potential and increase return on investment.