Search

Search

Search

Search

RockStrong FCS™ coring system obtains 122 ft. of 4 in. core with a 99.3% recovery rate

Download PDFMature Fields

Obtain first rock coring samples in soft unconsolidated sandstone formation

Thailand

An operator requested Halliburton Drill Bits and Services to perform its first conventional coring project in an offshore oil and gas field at a shallow depth with 35° deviated inclination.

This offshore environment is characterized as a soft, unconsolidated sandstone formation presenting risk of core milling/washing and poor recovery. There was no history for coring done in this field.

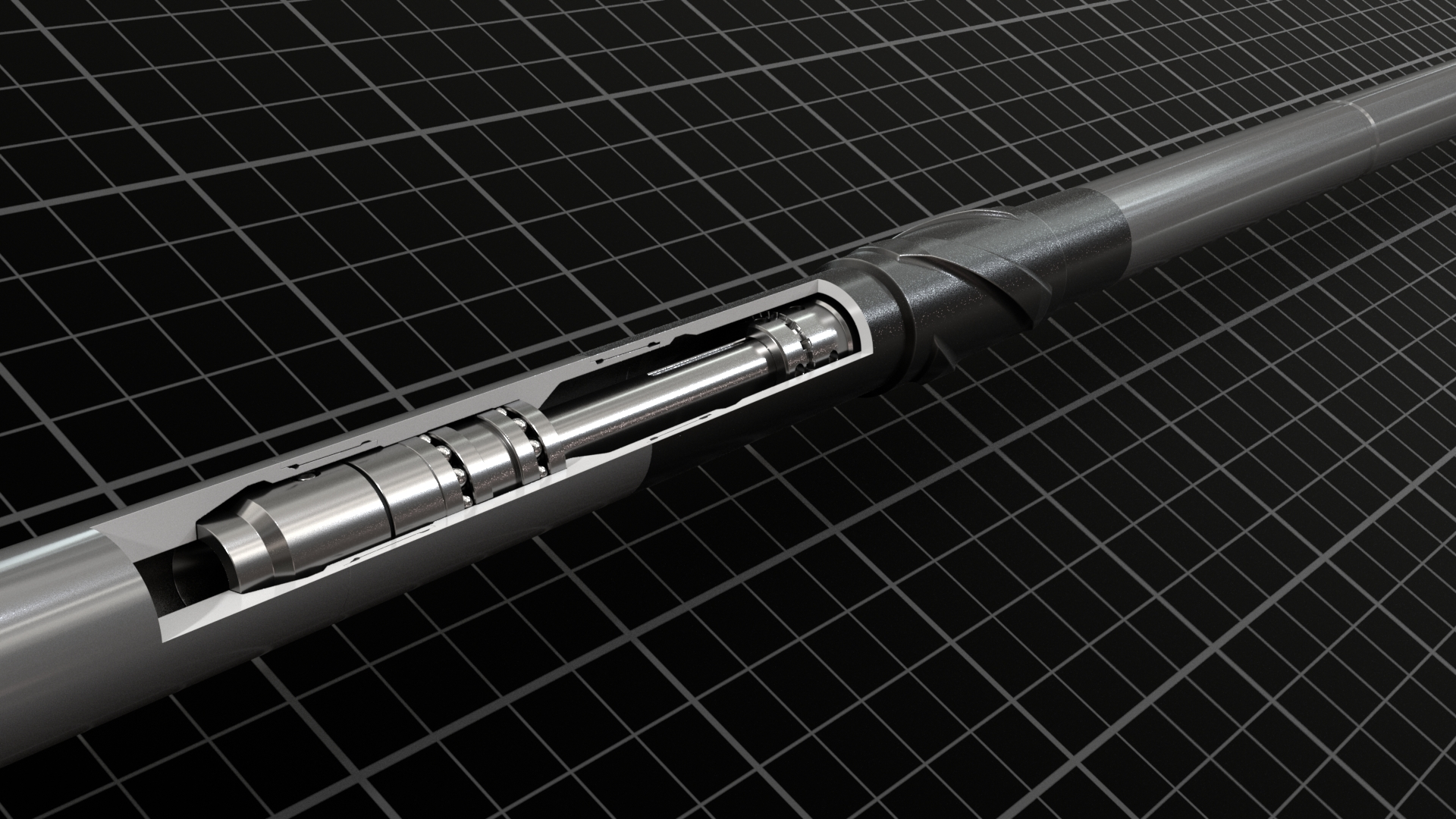

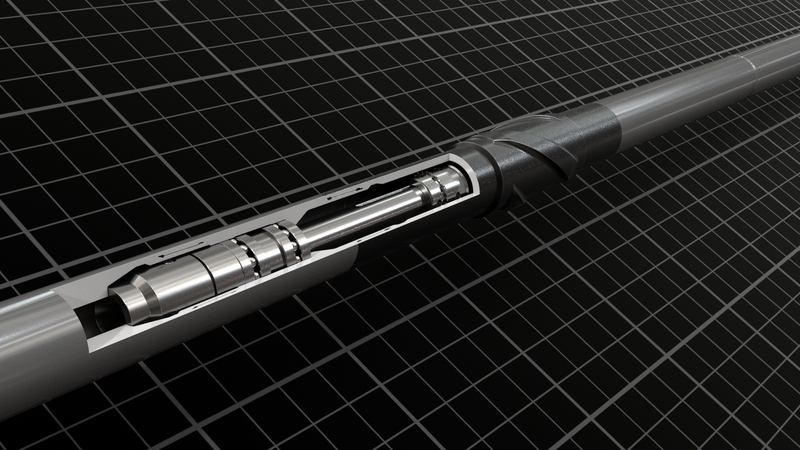

In collaboration with the operator, Halliburton carefully developed a detailed design of service to deploy the 6-3/4 in. RockStrong FCS™ coring system for a total of five runs to capture the soft, unconsolidated formation core samples. Once captured, core freezing and foam injection stabilization were used to transport the coring samples to the laboratory.

4 in. core captured

Core recovery rate

Core jamming was eliminated during all five runs using the RockStrong FCS coring system. With an 8-1/2 in. FC3743 core bit design, Halliburton captured 122 ft. of 4 in. core at a recovery rate of 99.3%.

Applying a core freezing technique, all fragile unconsolidated samples were successfully preserved, stabilized, and transported to the laboratory with minimal damage.

The operator obtained good core sample information to run further analysis on the field’s hydrocarbon viability. This efficient and well-coordinated operation was performed with zero nonproductive time (NPT) or health, safety, and environmental (HSE) issues.

The RockStrong™ coring and anti-jamming system was designed for maximum reliability under the harshest conditions.