Search

Search

Search

Search

RockStrong™ coring system vertically cored a total of 109 meters in three runs and achieved 100% high-quality core recovery with 100% core efficiency

Download PDFUnconventionals

Perform coring operation for carbon capture and storage campaign

Oman

An operator engaged Halliburton to perform a conventional coring operation to test the permeability of a targeted formation as part of a carbon capture and storage (CCS) campaign.

This unconventional formation is characterized by soft to medium interbedded sandstone and shale. The operator’s primary concern was downhole vibration and potential jamming upon increased parameters to gain rate of penetration (ROP).

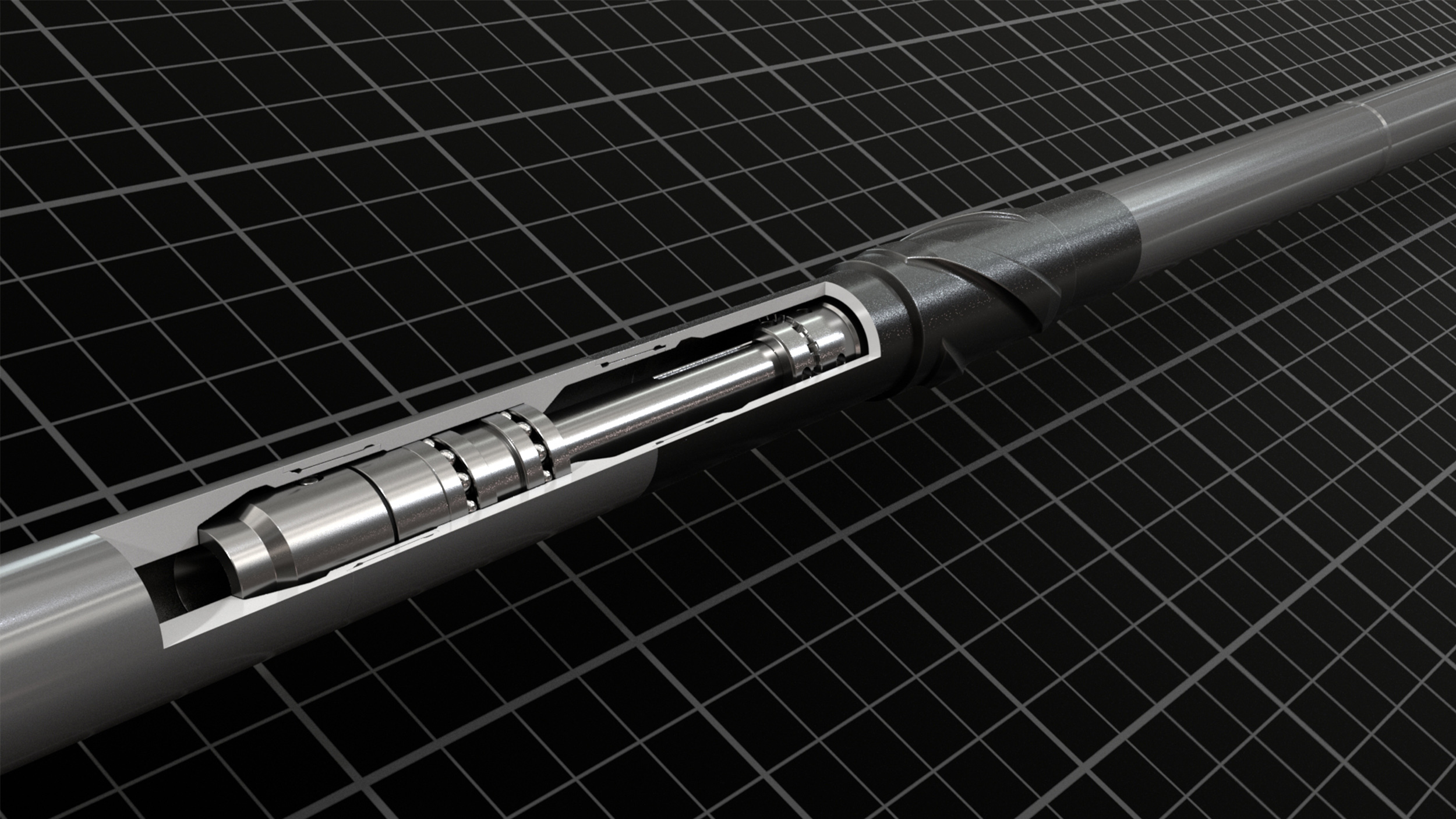

Halliburton developed an integrated solution within multiple product service lines that implemented lessons learned and knowledge gained from previous projects with the operator. The drilling team selected the RockStrong™ coring system for interbedded environments. This system features a unique swivel assembly designed with jam mitigation to operate reliably in extreme wellbore environments. Utilized unique modeling programs to better understand BHA and drill string dynamics.

Halliburton optimized a new generation core head design that consisted of an 8-1/2 × 4 in. FC74WRKs bit fitted with Machete™ cutters for drill bits, which pre-fracture rock through point loading, and Shyfter™ active backup elements for enhanced performance and maximum efficiency. The team optimized the core barrel length and coring road map parameters based on BHA modeling and previous coring experience.

Cored in three runs using single corehead

High-quality core recovery

Halliburton vertically cored a total of 109 meters in three runs and achieved 100% high-quality core recovery with 100% core efficiency. Core processing included marking, surface gamma ray logging, core stabilization, core preservation, and core packing. All three runs were completed using one corehead with zero NPT or HSE issues.