Search

Search

Search

Search

RockStrong™ coring tool and Cerebro® coring dynamics sensor help operator understand downhole dynamics

Download PDFMature Fields

High WOR and water disposal challenges limits production capacity

Colombia

With a history of high water/oil ratio (WOR) and water disposal challenges limiting production capacity in the Akacias field, an operator sought Halliburton Drill Bits and Services to help evaluate rock properties for water injection/disposal capabilities.

Earlier disposal wells had been drilled in the K1 formation and had experienced poor injection rates when put into service. The underlying K2 formation was selected as a potential injection point but there were no rock properties available for it in the Akacias field. In order to core K2, a challenging formation transition from K1 had to be cored. After entering the K2 formation, a long interval of over 360 feet needed to be cored at maximum efficiency.

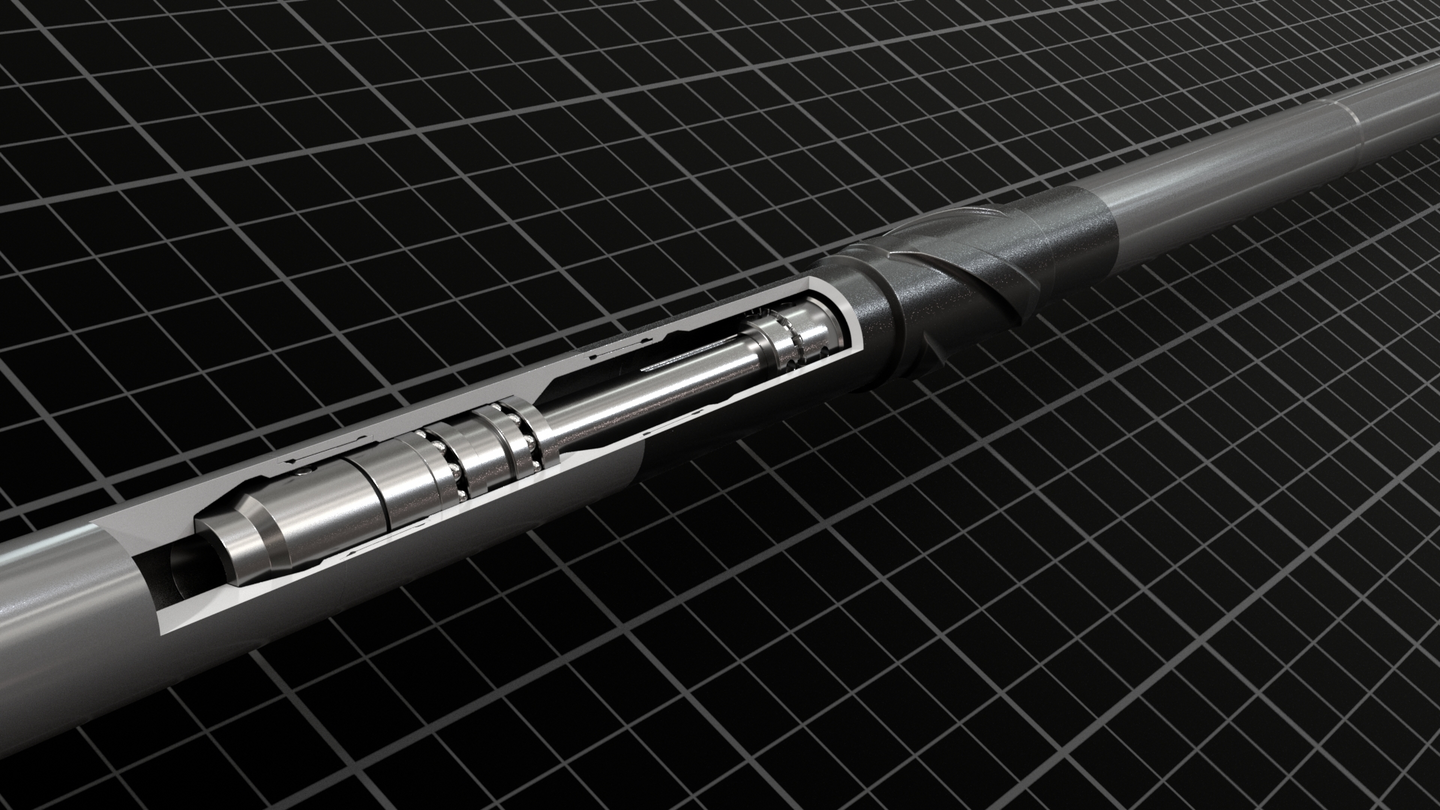

Halliburton proposed the RockStrong™ coring system because of its unique swivel assembly and anti-jamming design recognized for reliable operation in extreme wellbore environments without practical pressure or temperature limits to drill through the formation transition. This coring technology was paired with Cerebro® coring dynamics sensor to provide downhole data necessary to create a holistic picture of the coring environment, allowing the operator to make effective, data-driven decisions on coring surface parameters and equipment.

Hours of rig time saved

Saved

Core recovery rate

The anti-jamming capabilities of the RockStrong coring tool successfully cored the K1 to K2 transition with complete core recovery. Cerebro dynamics evaluated in between runs refined surface parameters and allowed core barrel length to be successively increased over the course of the four-run coring job.

The final coring assembly cored 151 feet of the K2 formation, completing the coring job with 100% core recovery. Longer core barrel assemblies saved one trip, reducing rig time by at least 48 hours, totaling approximately USD 220K saved to the Operator.