Search

Search

Search

Search

NeoCem™ system helps reduce cement operation carbon footprint and improves shear bond and wellbore integrity

Download PDFMature Fields

Reduce cement slurry carbon footprint and deliver effective zonal isolation

Ecuador

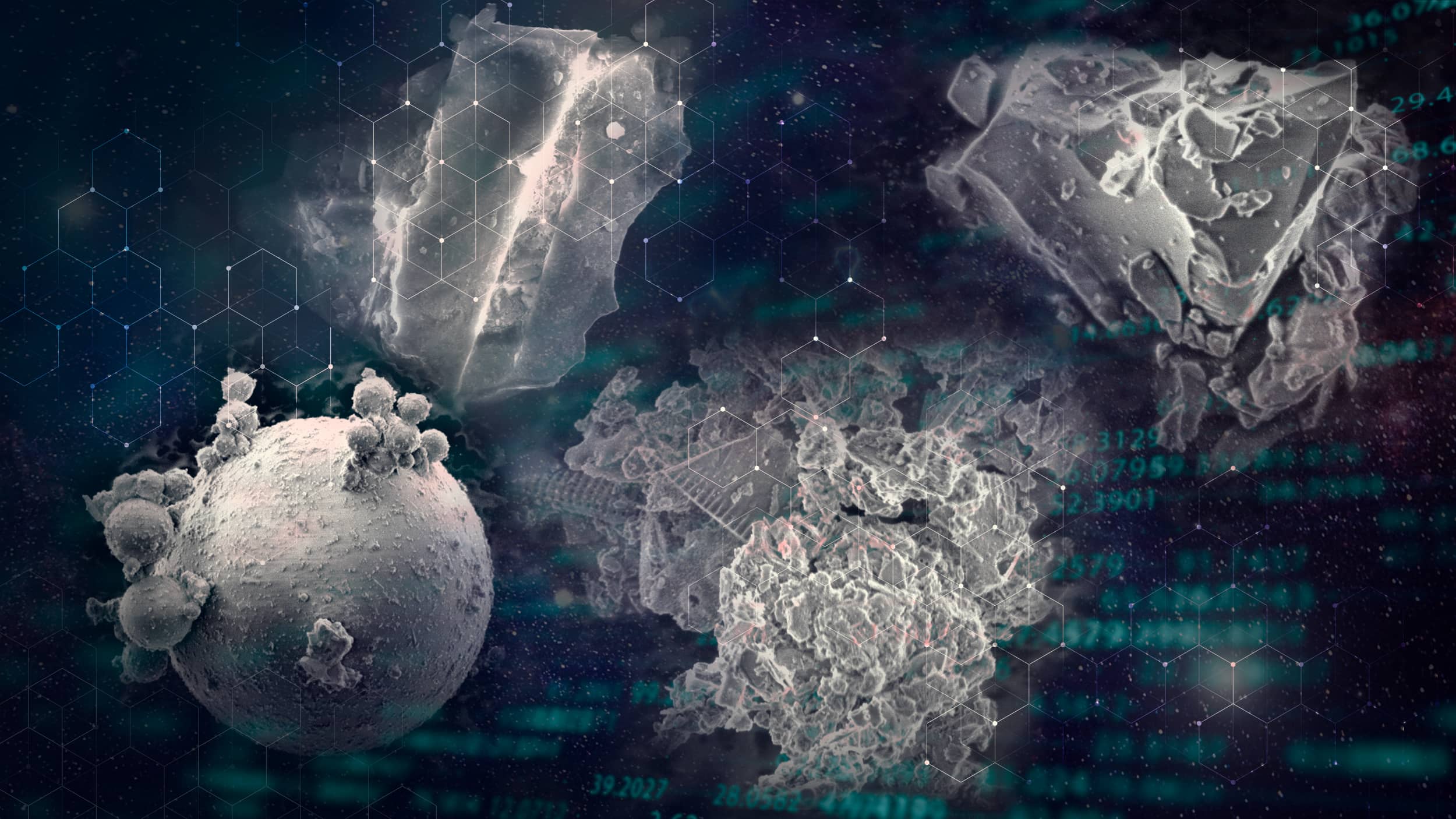

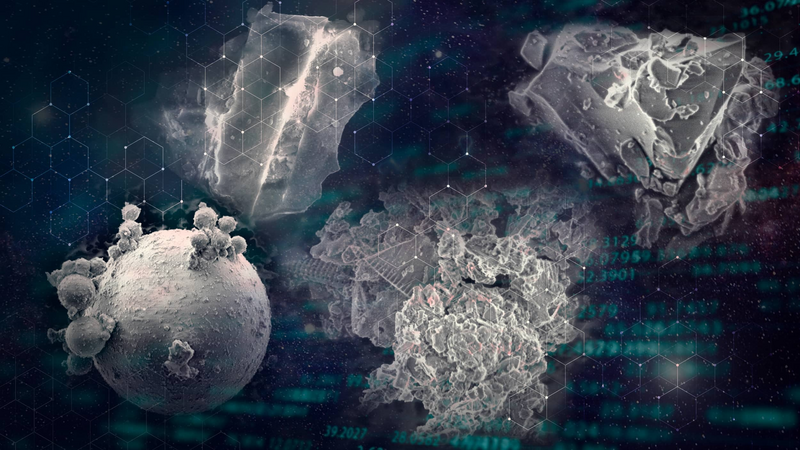

Portland cement is the main contributor to CO2 emissions associated with oil well cement operations. This is largely due to the energy-intensive manufacturing process and CO2 generated during the calcination reaction of limestone. As the industry transitions to a lower-carbon future, it is crucial to design cement barriers with reduced Portland content.

Andes Petroleum in Ecuador wanted to improve drilling efficiency in mature fields and minimize CO2 emissions from cement operations. A lighter weight slurry was required to help prevent lost circulation, maintain stability at bottomhole circulating temperatures (BHCTs) and bottomhole static temperatures (BHSTs), and provide adequate compressive strength and cement sheath ductility.

Halliburton proposed the NeoCem™ system, a reduced Portland system with improved mechanical properties compared to conventional systems. The NeoCem™ system reduces mass Portland cement content by up to 50% to help operators lower carbon emission baselines. Through an innovative tailoring process, the NeoCem system is engineered to deliver high-performance compressive strength and ductility at a lower density than conventional systems for improved barrier dependability.

Use in Ecuador

Reduction in mass Portland cement

Reduction in cement blend carbon emissions to date

Andes Petroleum was the first operator to deploy the NeoCem™ system in Ecuador, which has reduced the carbon emissions of the cement blend by 33.2%. The system provided enhanced mechanical properties, reduced the risk of induced fractures, improved wellbore integrity, and helped achieve increased zonal isolation reliability and cement bonds compared to conventional slurries.

The NeoCem system could play a pivotal role in helping the energy sector meet sustainability goals and maintain the efficiency and safety of wellbore operations, as indicated by the success achieved in Ecuador.

Reduced Portland content helps customers lower carbon emission baselines and provides engineered systems with enhanced barrier performance.