Search

Search

Search

Search

16-stages completed in 24 hours

Download PDFUnconventionals

Help operator reduce the cost per BOE and increase completion efficiency

Eagle Ford Shale

A 16-stage cemented RapidStage sleeve solution was proposed to help eliminate intervention

The operator saw a 66% increase in completion efficiency

An operator in South Texas wanted to improve well economics and lower the cost per barrel of oil equivalent (BOE) for a well in a new part of the Eagle Ford Shale. Looking for alternatives to the plug and perforate completion process, the operator sought new methods to complete and hydraulically fracture these new wells.

Halliburton proposed an unconventional completion solution comprised of RapidSuite frac sleeve systems. With this solution the operator was able to complete 16 fracture stages as designed in 24 hours compared to an estimated three days for a plug and perforate completions. This resulted in a 66% increase in completion efficiency, saving both time and money.

In unconventional plays like the Bakken, operators need to find ways to reduce both their costs and completion cycle time. Halliburton has proven time and again that RapidSuite sleeve systems can help overcome these issues more efficiently as compared to the commonly used plug and perf (PnP) methodology.

For this operator, the typical frac stage count they were getting by using PnP was seven stages per day. Higher stage count wells results in incremental costs associated with day rates, which impact the economic practicality of drilling and completing the well. They needed to find an alternative to PnP that would help eliminate intervention, thus saving time and money.

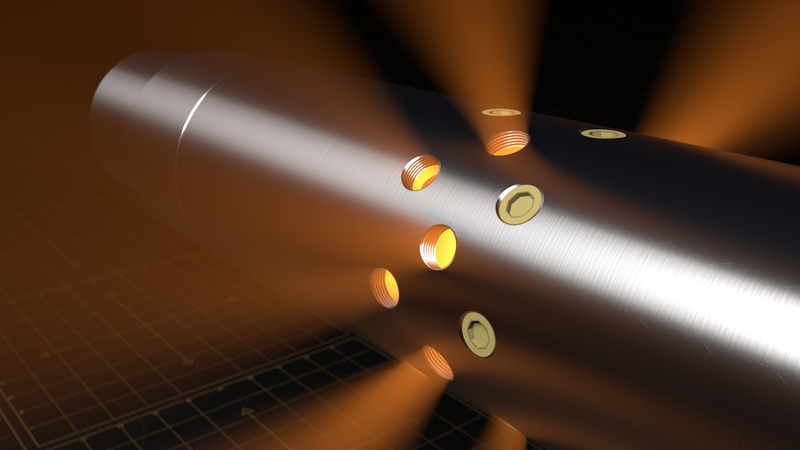

Halliburton proposed running a 16-stage cemented RapidStage system on a long string of production casing. RapidStage frac sleeves allow each stage to be fractured by dropping a ball from surface, thus helping to eliminate the need for wireline intervention. The process begins with the Halliburton RapidStart Initiator sleeve at the toe of the well to provide a flow path once opened with tubing pressure. Efficiency further increases when using the RapidSuite Pneumatic Ball Launcher to remotely release balls in the frac stream during continuous pumping. The entire completion is cemented in place with SoluCem® acid soluble cement to make fracturing the formation easier.

hours to complete all stages

fracture stages completed in 24 hours

increase in completion efficiency

With cemented RapidStage frac sleeves, the operator was able to complete 16 fracture stages as designed in 24 hours compared to an estimated three days for a plug and perforate completion. This represented a 66% increase in completion efficiency, saving both time and money. Production results were also similar to offset wells, helping ensure that the RapidStage system could reduce the cost per BOE.

Single-and multi-entry sleeve systems for accurate stimulation placement without intervention

Download Data Sheet

RapidStage® frac sleeve systems optimize multistage completions by accurately placing stimulation treatments without intervention.