Search

Search

Search

Search

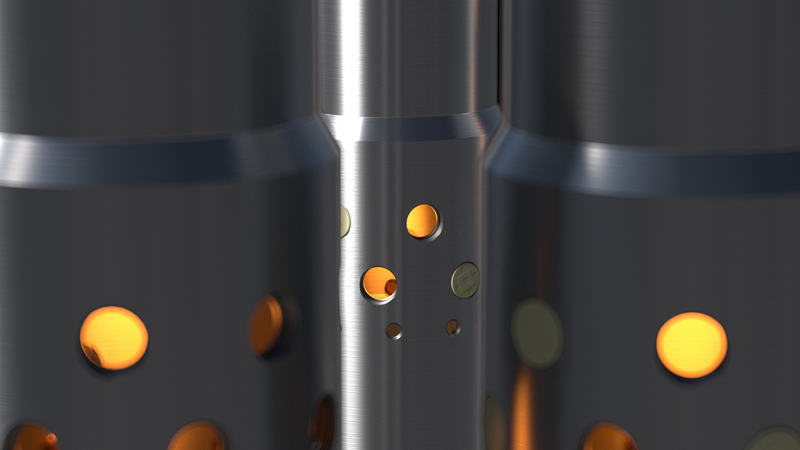

Seneca Resources opted to use RapidStage® ME (multi-entry) sleeves to eliminate the non-productive time

Download PDFUnconventional

Achieving an efficient solution to help reduce overall completion costs

Elk County PA

In Elk County Pennsylvania, Seneca Resources was looking for ways to further improve completion efficiency, reduce cycle time, and eliminate drill out of their extended reach laterals. They also wanted to improve their average stage count per day. Seneca opted to use RapidStage ME (multi-entry) sleeves to eliminate the non-productive time associated with running plugs and perforating guns on wireline, saving time and reducing the overall cost of the frac job.

Further efficiency was gained by using dissolvable ball technology combined with larger ID baffles. By pairing these technologies, Seneca eliminated the need to drill out the toe of their extended laterals.

eneca needed to complete an extended reach lateral (ERL) well with an efficient, cost-effective, low risk solution. In ERL wells, all operations and their risks are amplified due to the intense nature of the well’s conditions. Extreme measured depths lead to higher risk coiled tubing operations and extended run times for both coil and wireline units. This can ultimately lead to an inefficient use of time and the increased chance of more costly problems. In ERL wells, the bottom line is that efficiency reduces costs, and traditional methods of completion are often unable to excel in these environments.

When looking to increase completion efficiency in their extended reach laterals in the northeastern US, Seneca Resources chose to run the RapidStage ME sleeve system in the first three stages of their trial well for a total of four entry points per stage, or 12 sleeves.

Each stage was optimized for both the ball landing signatures and the best treatment design. The system comprised four RapidSuite™ technologies including RapidBall dissolvable balls, RapidStage ME, RapidStage SE (single-entry) sleeves, and a RapidStart Initiator CT sleeve at the toe of the well. This system provided an extended lateral solution by helping to eliminate the need to drill out the baffles before starting the well on production.

The RapidStage ME sleeve system creates a multiple entry point completion design with greater efficiency and fewer interventions. Initial communication into the formation is achieved with the RapidStart Initiator CT (Casing Test) sleeve. The opening of the Initiator sleeve allow the RapidBall DM (Dissolvable Metal) balls to be pumped down hole in order to activate the RapidStage ME sleeves.

The ball passes through the baffles of the RapidStage ME sleeves, exposing ports, and landing on the RapidStage single-entry sleeve.

RapidBall DM self-removing ball technology creates a temporary bottom plug that dissolves over time. During the frac, the ball provides a solid plug to direct the frac fluid into the open ports of the current stage, while isolating the stages below. Post frac, the ball dissolves to achieve production, without having to drill out the ball or baffle.

By combining RapidSuite systems, Seneca was able to reduce the downtime typically associated with wireline operations. This completion method also extended the lateral, saving both time and money typically spent on workovers and coiled tubing, which require drilling out of these stages prior to putting the well on production.

hours reduced in cycle time

ball or baffle drill outs

sand placed

hours saved and risk reduced milling out plugs

The RapidStage ME system opened as designed and placed 100% of the sand while achieving the designed job rates. Solid ball signatures were achieved, verifying that all tools were open. By partnering with Halliburton, Seneca was able to save over six hours and reduce the risk often times seen in extended laterals when milling out conventional plugs.

RapidStage systems optimize the completion of multistage wellbores by enabling highly accurate placement of stimulation treatments without intervention.

Download Data SheetThe RapidStart Initiator CT sleeve is a pressure-operated fracturing sleeve designed to enable a casing pressure test prior to opening and establishing a fluid flow path to the target formation.

Download Data Sheet

Maximize production with multistage fracturing completion systems that help reduce stimulation time and offer selective zonal treatment.