Search

Search

Search

Search

‘No-Access Active Ranging’ intercepts a troubled well for plug and abandon and saves over 25 days for customer

Download PDFMature fields

After five failed sidetracks, the operator needed advanced ranging to intersect

United States

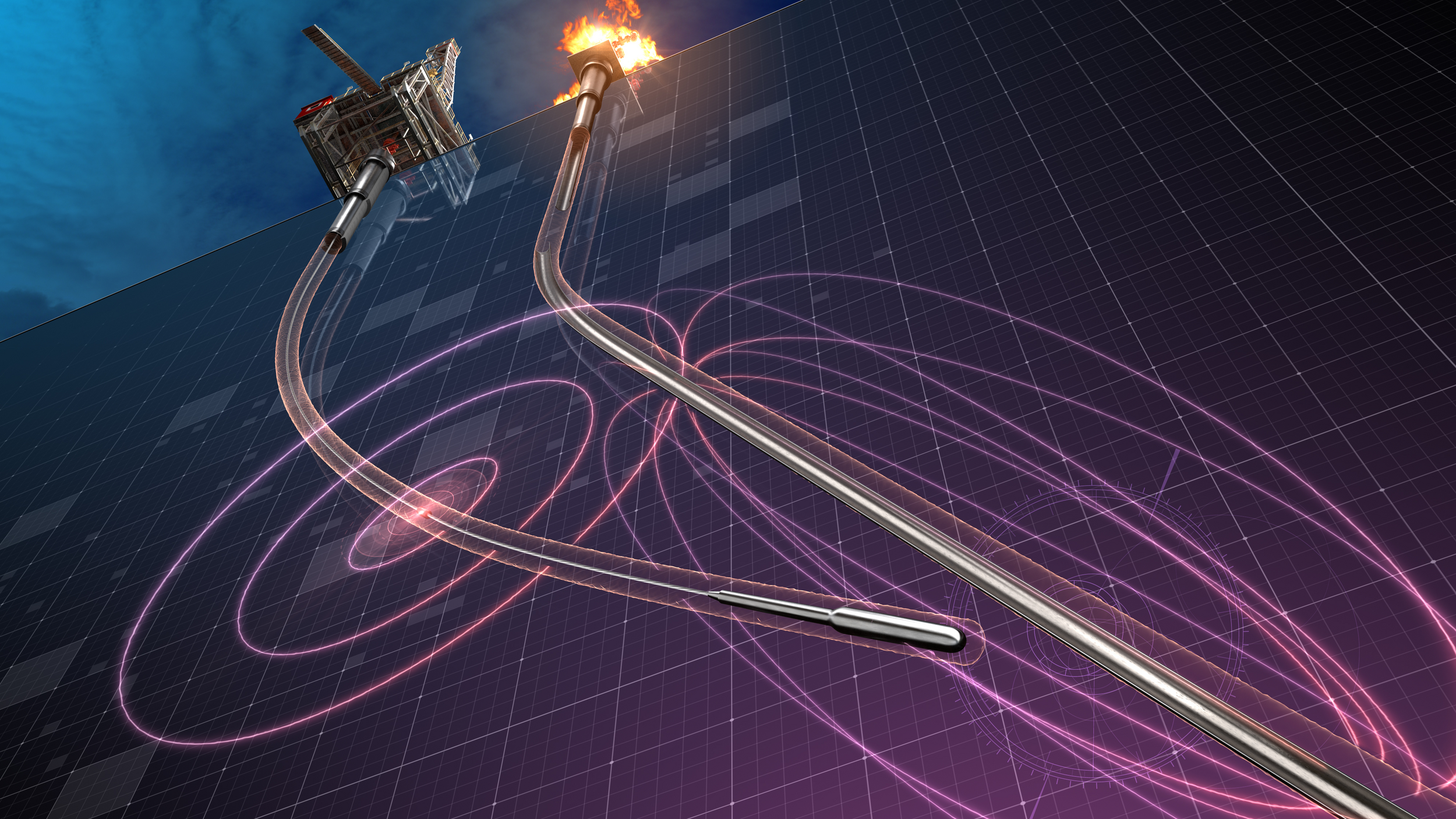

After five sidetracks and subsequent failed attempts at a wellbore intersection, an operator with a plug and abandon operation called on Sperry to intervene and deploy a solution with a proven track record of success. Sperry Proximity Ranging & Interception group used access independent active ranging to successfully intercept the well. Damaged casing in the well resulted in the need for the operator to plug and abandon (P&A) the well. The P&A operation required a new well to be drilled at a well bore separation of between two and four feet to a depth from 780 feet (238 meters) down to interception point at 1350 feet (411 meters). After interception of the wellbore, the plan called for a milling operation to open the casing with an 8-1/2 inch mill to allow re-entry of the 5-1/2 inch casing by a 2-7/8 inch coiled tubing.

To achieve the precision and efficiency required for the distance and direction between wellbores, Sperry ran the WellSpot™ Radial Gradient Ranging (RGR) Access Independent tool for a total of 16 ranging runs over three phases of the operation of locate, follow, and interception. The initial ranging phase located the target well at 754 feet (228.5 meters) Measured Depth (MD), showing a distance of 8.2 feet (2.5 meters) at a high side to target of -45 degrees.

In the following phase, WellSpot RGR guided the drilling well and sustained an accurate alignment to the target well until the interception phase. To ensure the well path remained on target and within the gradient detection range, WellSpot RGR runs were made every 30 feet (9 meters) during the follow phase, then decreased the drilling interval to every 10 or 15 feet (3.0 or 4.6 meters) in the interception phase until edge to edge contact was made at 1,370 feet (418 meters), where the milling operations began.

days to completion vs 50+ days by third party

USD saved

Sperry Proximity Ranging & Interception faced a damaged well that had eluded detection by a third party, who had drilled five sidetracks without success. Considering the time and cost already involved, the operator emphasized that the goal was to drill a smooth wellbore while staying within two to four feet (0.6 to 1.2 meters) of the target well to correctly align and have a simplified milling operation so that tubing could be re-entered to plug and abandon the damaged well. Because the ability to use both passive and active technologies vastly improves the likelihood of a successful intersection, Sperry deployed both active and passive ranging tools to the job. Using WellSpot RGR active ranging exclusively in this case, Sperry intercepted the lower casing with a single wellbore and performed a successful milling operation to open up the lower casing, and then ran tubing to plug and abandon the well. The results exceeded expectations as the main objective was completed without NPT or any HSE incidents. By providing an efficient and successful solution, Sperry’s Active Magnetic Wellspot Ranging System saved the operator an estimated $2.5 million by eliminating additional time to drill costly extra sidetracks as had been previously recommended by a third party.

Magnetic ranging solutions demonstrate a well-established history of expertise, proving our dedication to precision when navigating the intricacies of well proximity applications