Search

Search

Search

Search

No extra sidetracks for active ranging service

Download PDFDeep water

Plug and abandon an offshore well with a damaged wellhead

India

Due to a damaged well head, an operator with an offshore well in India was faced with drilling a relief well to complete a plug and abandon operation (P&A). The primary challenge was a large ellipse of uncertainty as the target well was drilled to a depth of 13,780 feet (4200 meters) without directional surveys. Adding to the complexity of the P&A operation was the distance of the planned relief well, at over 1,050 feet (320 meters) away. It was critical that the ranging service provide the largest possible depth of investigation to guide the relief well to the target well and avoid additional expensive sidetracks. An additional challenge was to operate in the static temperature exceeding 356 degrees Fahrenheit (180 degrees Celsius) in the final section of the well.

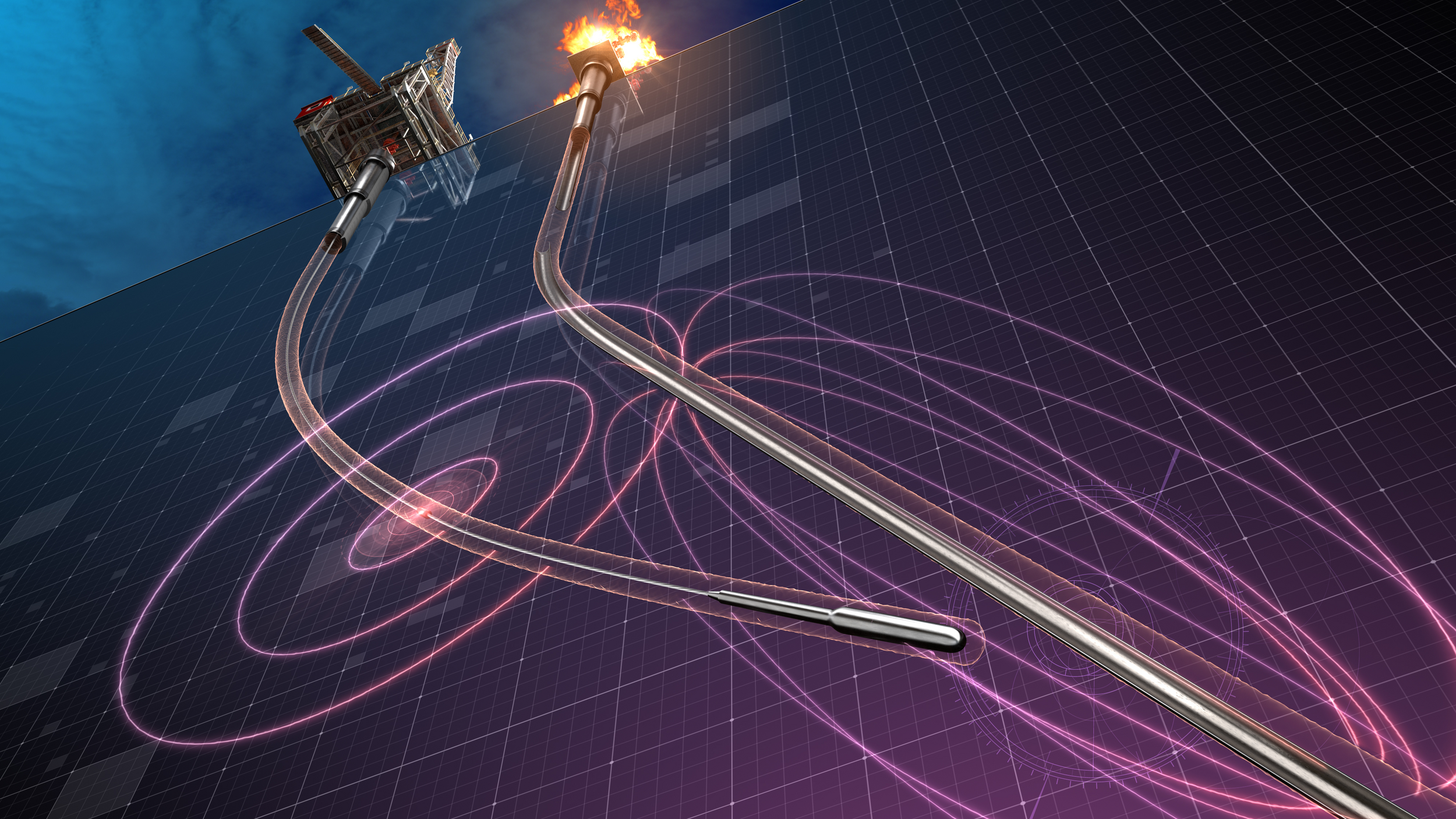

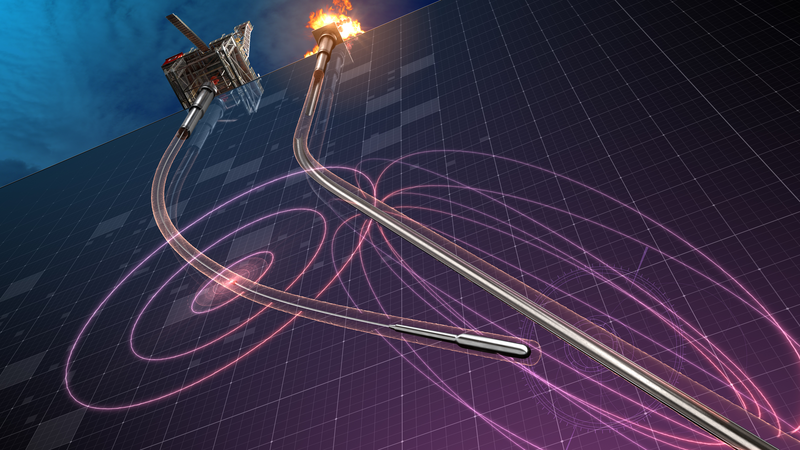

The Sperry Proximity Ranging and Interception group was called to provide a solution to accurately determine direction and distance between wellbores to intercept the target well from the relief well. To mitigate the damaging impact of the high static temperature in the final hole section, the WellSpot™ assembly was deployed in an active magnetic ranging BHA, which provided the ability to circulate around the wireline-deployed assembly that helped ensure the WellSpot data was reliably collected for the intercept phase.

The relief well was planned based on the leading industry detection range and accuracy of the WellSpot™ system. As planned, the initial detection phase was established at 5,905 feet (1800 meters) MD with separation of over 65 feet (20 meters) between the target and relief well. With 5,577 feet (1700 meters) remaining to drill before the start of the intercept phase, the accuracy and detection range of the WellSpot service allowed the follow phase of the relief well to be confidently drilled without the risk of an accidental interception or the loss of detection of the target well. At 12,139 feet (3,700 meters), the relief well was gradually guided from a 16 foot (5 meter) separation to interception at 13,451 feet (4,100 meters). The direct distance measurement capability of the WellSpot gradient sensors helped ensure that the relief well was placed in the exact location to complete the plug and abandon job.

feet drilled without directional surveys

static temperature of intercept point

measured depth separation between wells

Early identification of the distance and direction between a relief well and target well along with accurate distance and direction measurements between wellbores is critical in efficiently and effectively intercepting a relief well. Failure to achieve both of these consistently in the magnetic ranging operation can result in costly remedial operations such as sidetracking to reposition the relief well. In an offshore environment, a sidetrack can easily lead to weeks of flat time from the extra trips needed to cement and re-drill the section. Utilizing the industry leading magnetic ranging system from Sperry Drilling services, the WellSpot system can help minimize this risk and can save one or more sidetracks – with savings in the tens of millions of dollars.

WellSpot™ active magnetic-ranging systems use precise sensors to provide data for multiple drilling applications.

Magnetic ranging solutions demonstrate a well-established history of expertise, proving our dedication to precision when navigating the intricacies of well proximity applications