Search

Search

Search

Search

Tailored cement design uses Tuned® Defense™ cement spacer, BridgeMaker™ II LCM, and Super CBL™ EXP additive to minimize lost circulation and fluid influx

Download PDFMature Fields

Achieve top of cement (TOC) in a narrow pore and fracture pressure window

Middle East

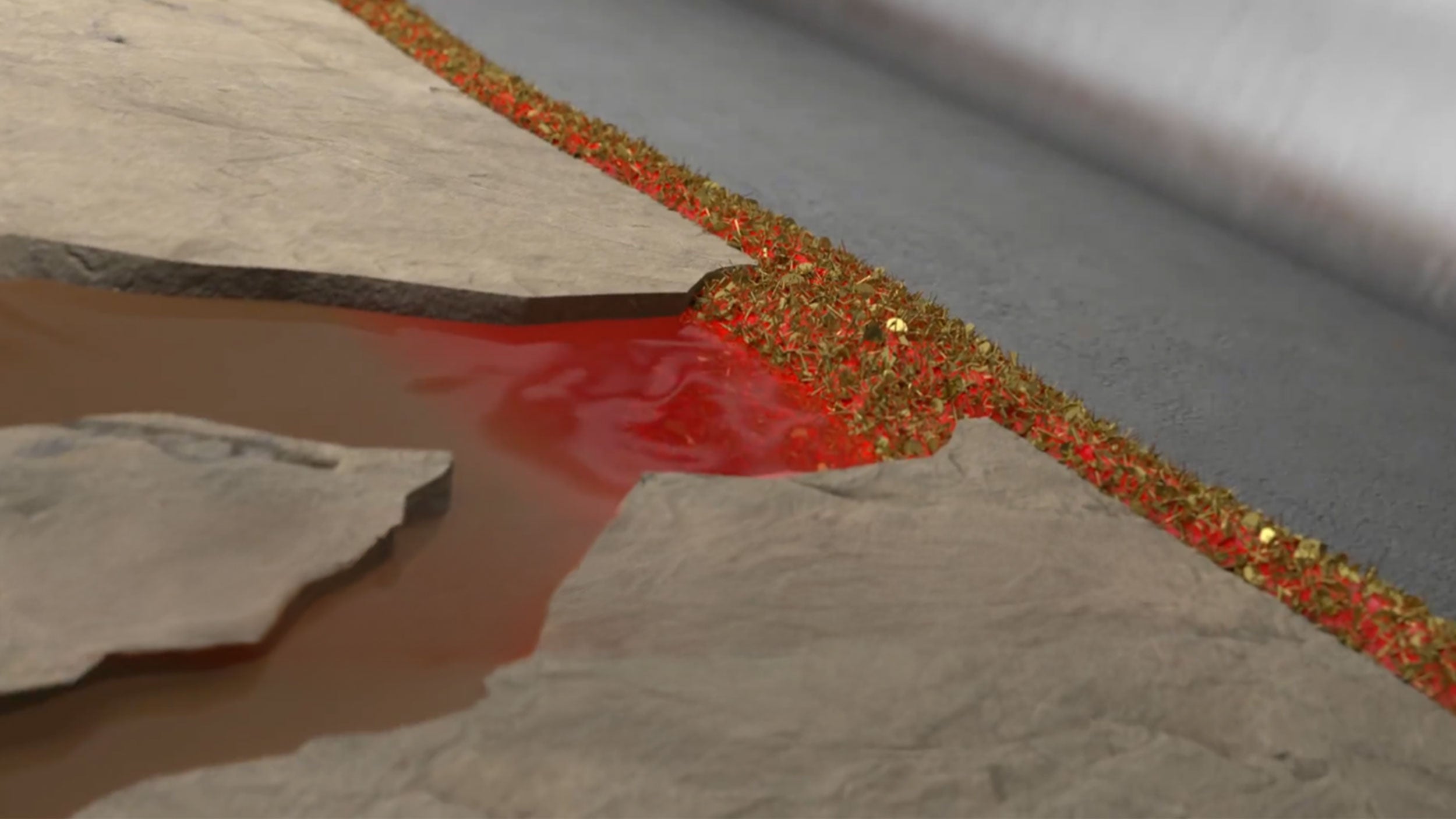

Cementing operations in formations with narrow pore pressure and fracture gradients pose significant challenges. These environments increase the risk of lost circulation and fluid influx into unset cement, which can compromise zonal isolation by creating channels in the cement barrier. Achieving optimal cement placement is essential to maintaining long-term wellbore integrity.

Halliburton recommended a tailored cementing strategy using the Tuned® Defense™ cement spacer combined with BridgeMaker™ II lost circulation material (LCM) to prepare the annulus and reduce the risk of lost circulation.

A heavyweight cement slurry was formulated with Micromax additive and latex to deliver sufficient overbalance in the zone of interest, minimize permeability, and achieve optimum cement transition time. To further improve bonding and reduce gas migration risk, Super CBL™ EXP additive was included in the slurry design.

To help ensure effective displacement and manage equivalent circulating density (ECD), Halliburton modeled the cement and spacer properties using its iCem® cementing service hydraulic modeling software. Managed pressure cementing (MPC) techniques were also applied to minimize the potential for fluid influx during placement.

Objective met

Confirmed full cement coverage

Channels caused by fluid influx

The operation achieved full returns during displacement, confirming successful mitigation of lost circulation. Real-time monitoring validated lifting pressures and confirmed that the planned top of cement (TOC) objective was met.

Field observations showed that both spacer and cement were circulated off the top of the liner, indicating full cement coverage. Cement bond log (CBL) evaluations confirmed strong bonding throughout the zone of interest, including the 4 1/2-in. (114-mm) openhole liner and remedial scab, with no evidence of channeling or fluid influx.

Tuned® Defense™ cement spacer systems prevent lost circulation while optimizing fluid rheology for effective mud displacement.

Improves cement spacer designs to prevent lost circulation.

Cementing barrier design and tailoring digital twin software that enables real-time job monitoring, evaluation, and instantaneous barrier validation.