Search

Search

Search

Search

First deployment of BHKA™ plug setting disconnect tool in West Africa improves operational efficiency

Download PDFDeepwater

Reduce operational time to abandon target zone

West Africa

To improve drilling performance, significant resources are dedicated to well design, directional services, bit selection, drilling fluid, etc. However, operators can achieve significant rig time savings by simplifying temporary or permanent abandonment programs in exploratory or development wells.

A major operator with shelf and deepwater assets in Sub-Saharan West Africa plans several exploratory and development wells, which require temporary and permanent abandonment programs under various conditions. The operator’s standard operational procedures require isolation of each hydrocarbon-bearing zone via conventional cement plug placement with verification after waiting on cement (WOC).

In a previous exploratory well, the operator’s final abandonment program required the placement of five stacked cement plugs to isolate each target zone. The program was executed successfully over eight days but incurred USD 3.1 million in overall costs associated with rig time.

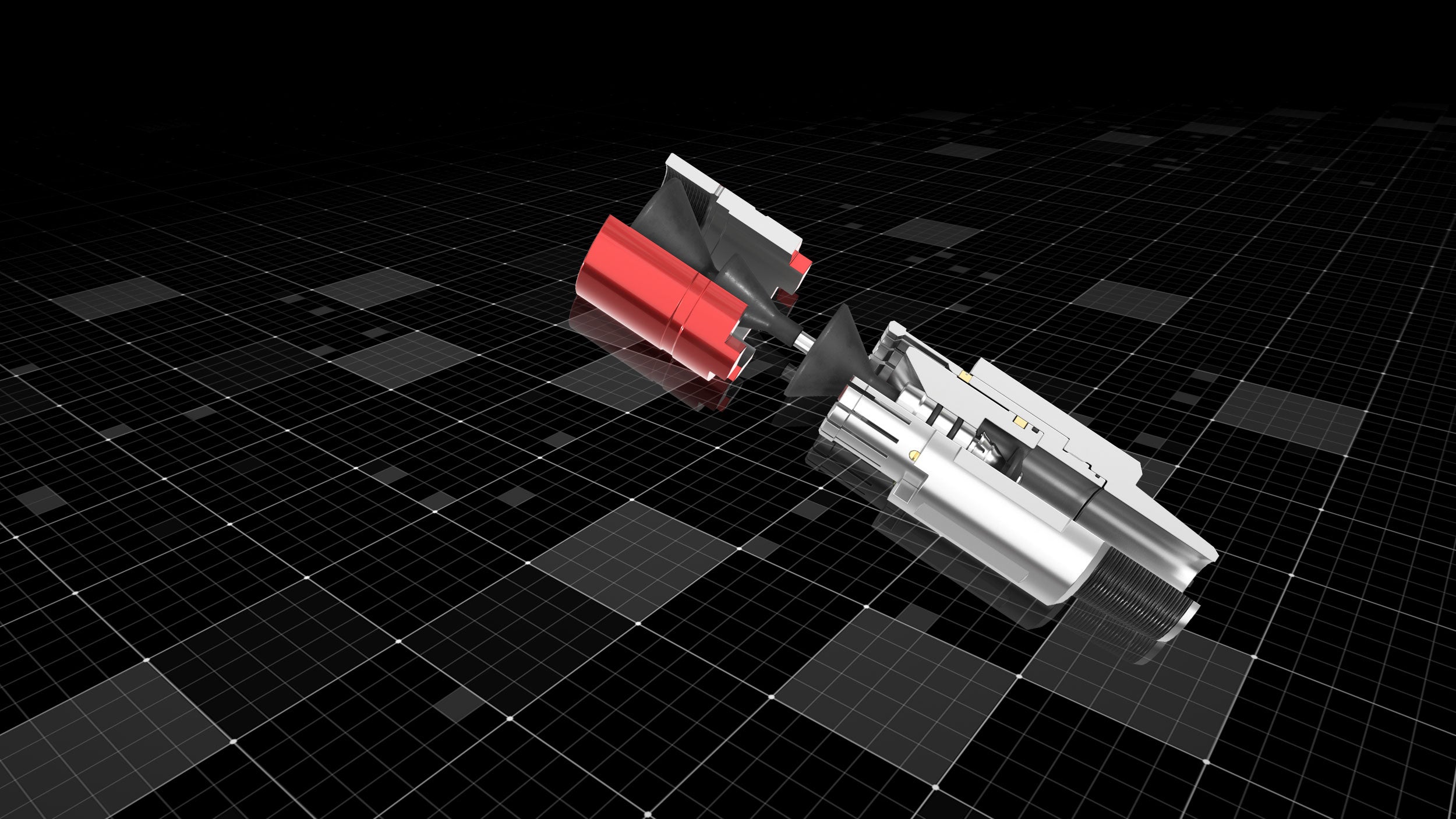

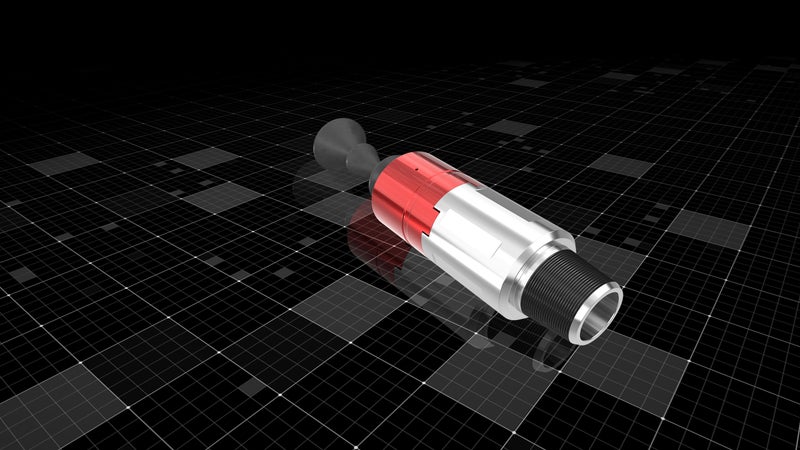

To reduce the total cost of ownership (TCO), Halliburton recommended incorporating the BHKA™ plug setting disconnect tool to simplify cement plug setting procedures. This tool replaces consecutive stacked plugs with a single, longer cement plug. The BHKA plug setting disconnect tool facilitates unlimited cement plug length through safe disconnection of the work string from the tail pipe, which reduces the risk of a stuck string and eliminates the need for multiple plugs and WOC in between plugs.

Trial operations

Hours rig time saved

Million USD saved

Future wells planned

The operator agreed to deploy the BHKA™ tool for a trial operation to analyze the results and evaluate its application in future wells. Halliburton tailored the operational design for two applications as a proof of concept.

The first application, designed to permanently abandon the 12 1/4-in. pilot hole of a deepwater producer well, consisted of a 5-in. outside diameter BHKA tool with 400 m of 4 1/2-in. sacrificial tail pipe, run in hole with a 5 7/8 × 3 1/2-in. combined drillpipe work string. The operation was executed in adherence to the cement program. Halliburton deployed an MCXV releasing dart from the Commander™ 1000 cement head and displaced it to land and operate the single-collet release mechanism at a differential pressure of 2,600 psi. The tail pipe released, achieving planned coverage above the target zones in the pilot hole.

The next deployment was in an exploratory well, where the solution was designed to replace two subsequent 200-m-long cement plugs with a single cement operation to achieve the required isolation. Similar tubulars and the BHKA tool were used. The cement operation proceeded as planned and was completed with the release of the sacrificial tail pipe and differential pressure of 2,200 psi applied on the landed dart. The objective to provide 100 m of isolation above the target zone was achieved on the first attempt.

The successful proof of concept demonstrated the tool's reliability to the operator, familiarized them with tool procedures, and confirmed potential savings if implemented in future wells.

Modifying the abandonment strategy to permanently isolate the pilot hole resulted in an estimated savings of USD 2.3 million and 132 hours of rig time. The operator now plans to use the BHKA tool in four additional wells in the region, potentially saving up to USD 13 million.

The Halliburton BHKA™ plug setting disconnect tool simplifies cement plug placement when necessary during well construction or abandonment operations.

Designed for offshore operations to surface launch balls or darts in order to operate subsea plug sets and associated tools.