Search

Search

Search

Search

Trial with BHKA™ plug setting disconnect tool demonstrates benefits of cement plug placement during P&A and saves days of rig time

Download PDFPlug and abandonment

Place 500-ft long competent cement plug to abandon openhole in single run

Middle East

Plug and abandonment (P&A) programs are regularly performed in complex conditions. This makes the successful placement of a competent cement plug as a barrier on the first attempt uncommon. Reattempts to place plugs add significant cost and time to abandonment operations.

An operator was challenged with the effective abandonment of a 5 7/8-in. openhole at 16,000 ft MD. The slim hole design and total depth complicated the cement fluid design and competent cement plug placement. These operations often lead to remedial actions, which increase operational time and costs.

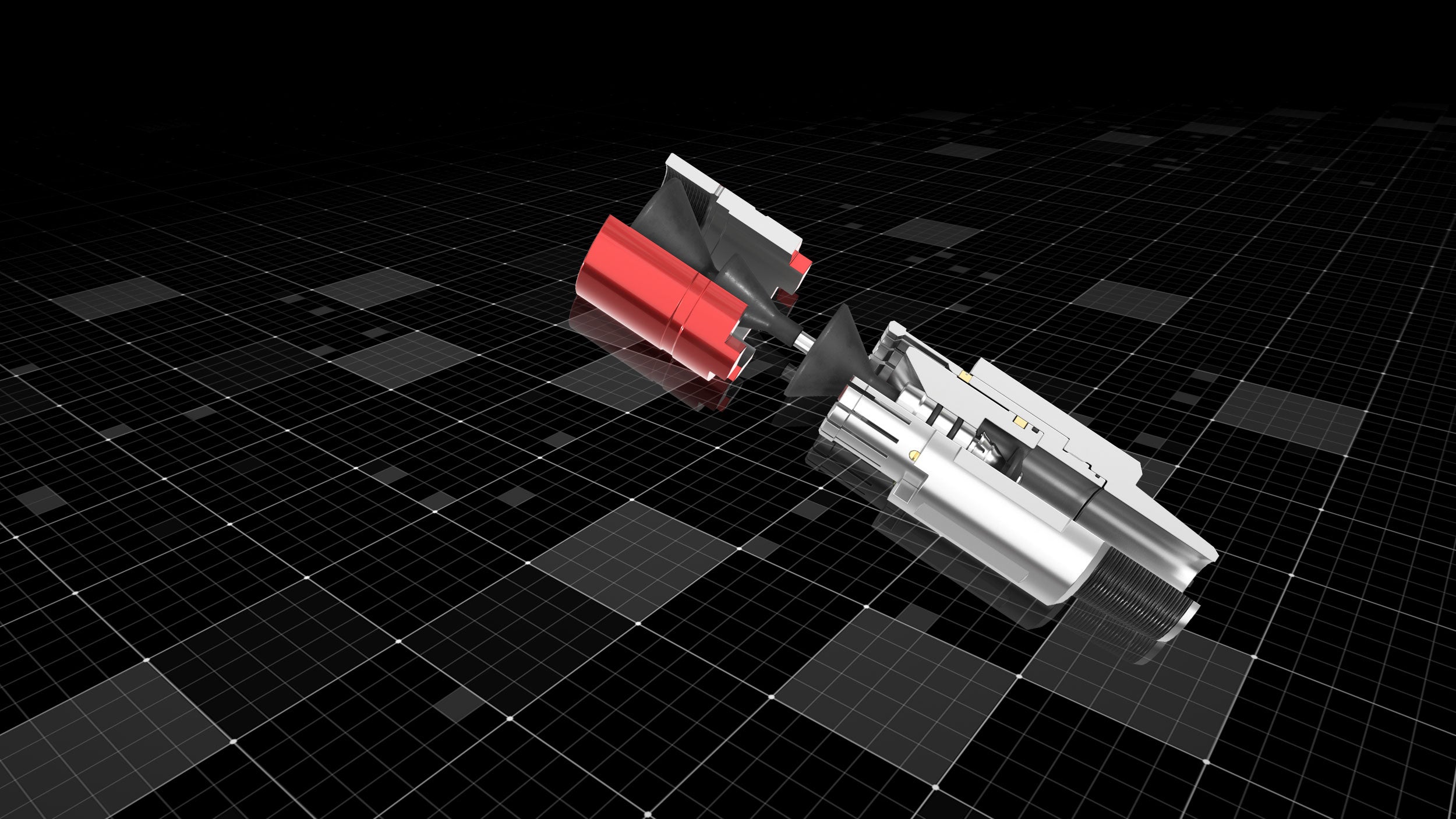

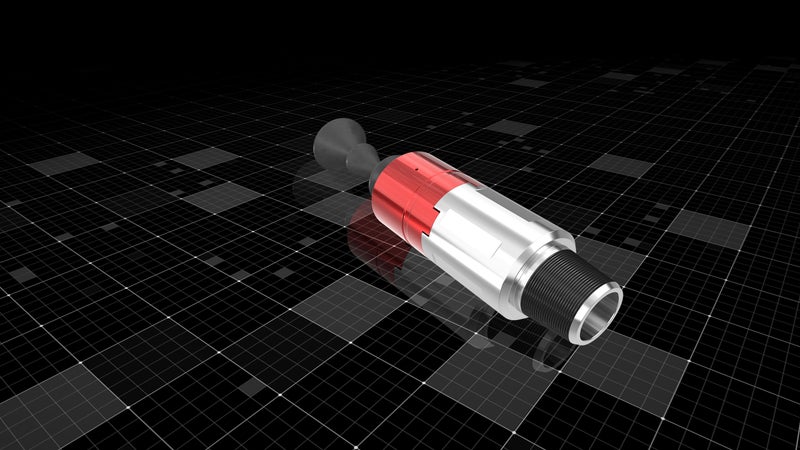

Halliburton proposed a trial deployment of the BHKA™ plug setting disconnect tool with an aluminum sacrificial tailpipe to successfully place the 500-ft long cement plug in a single run and achieve the required barrier. The BHKA tool enables unlimited cement plug length through safe disconnection of the work string from the tailpipe, reduces the risk of stuck string, improves the capability to tailor cement fluids, and eliminates the need for multiple plugs and associated WOC time.

ft MD safe RIH

ft long cement placed in single run

Estimated days rig time savings

Halliburton ran the string to the planned depth of 16,000 ft MD with the sacrificial tailpipe and BHKA tool and placed the 500-ft cement plug in a single operation. This was confirmed via surface indication of proper separation of the returned workstring from the sacrificial tailpipe. Successful separation eliminated the need to retrieve pipe from within the cement plug. This allowed the cement plug to develop gel and compressive strength without disturbance.

The operator saved an estimated one to two days of rig time with this successful trial deployment of the BHKA tool. Because of this success, the operator plans to use the BHKA tool solution in future wells.

The Halliburton BHKA™ plug setting disconnect tool simplifies cement plug placement when necessary during well construction or abandonment operations.