Search

Search

Search

Search

BHKA™ plug setting disconnect tool delivered dependable barrier for the permanent plug and abandonment of mature-well in Middle East

Download PDFPlug and abandonment

Perform permanent plug and abandonment of 7,000-ft interval

Middle East

Achieving an efficient and dependable barrier during plug and abandonment (P&A) operations can be challenging. Often, these activities rely on repeated stacking of cement plugs to cover the full length to be isolated and remedial operations to correct the lack of pressure-bearing capabilities. In addition, operational risks could be incurred if the conventional boundaries for cement slurry design are exceeded.

An operator was challenged with the effective abandonment of a 7,000-ft interval inside a 7-in. cased hole. The conventional method of stacking cement plugs requires excessive operational time because of the 650-ft plug length and the wait on cement (WOC) time needed between each plug. The small casing inside diameter (ID) increased the risk of cement slurry contamination and cement plug integrity. Safe cement placement and successful plug tagging were required to achieve the wellbore integrity necessary for permanent well abandonment.

Halliburton and the operator devised a safe and effective strategy to execute the P&A program and achieve objectives. Halliburton proposed the BHKA plug setting disconnect tool for its successful application history during offshore jackup operations in the country.

The slurry was designed to ensure safe placement, proper zonal isolation, and hard cement after the required WOC. It focused on a fast initial set, overall strength development, and safe pumpability time.

bbl cement slurry pumped and placed

Tagged 10 ft above planned depth

Days rig time saved

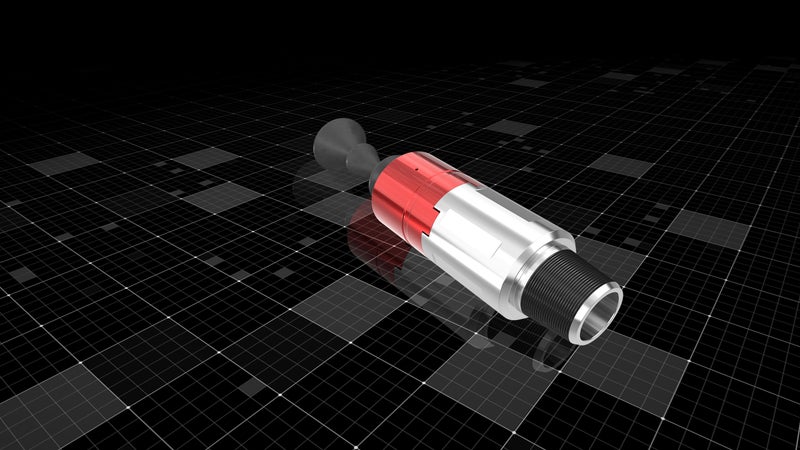

A total of 7,000 ft of sacrificial pipe was connected to the retrievable section of the string via the BHKA plug setting disconnect tool and run in hole (RIH) to the final depth of 8,700 ft MD.

At depth, the cement operation was performed and fluid was placed after the approved program. A displacement dart was used to separate fluid and function-release the sacrificial tail pipe. The release mechanism operated as desired. This enabled the operator's first single-stage abandonment plug operation onshore, which extended beyond 7,000 ft in length.

After WOC, the crew tagged the top of the plug and performed successful pressure integrity tests, both critical requirements for the well abandonment. Job objectives were achieved, and the operator saved two days of rig time.

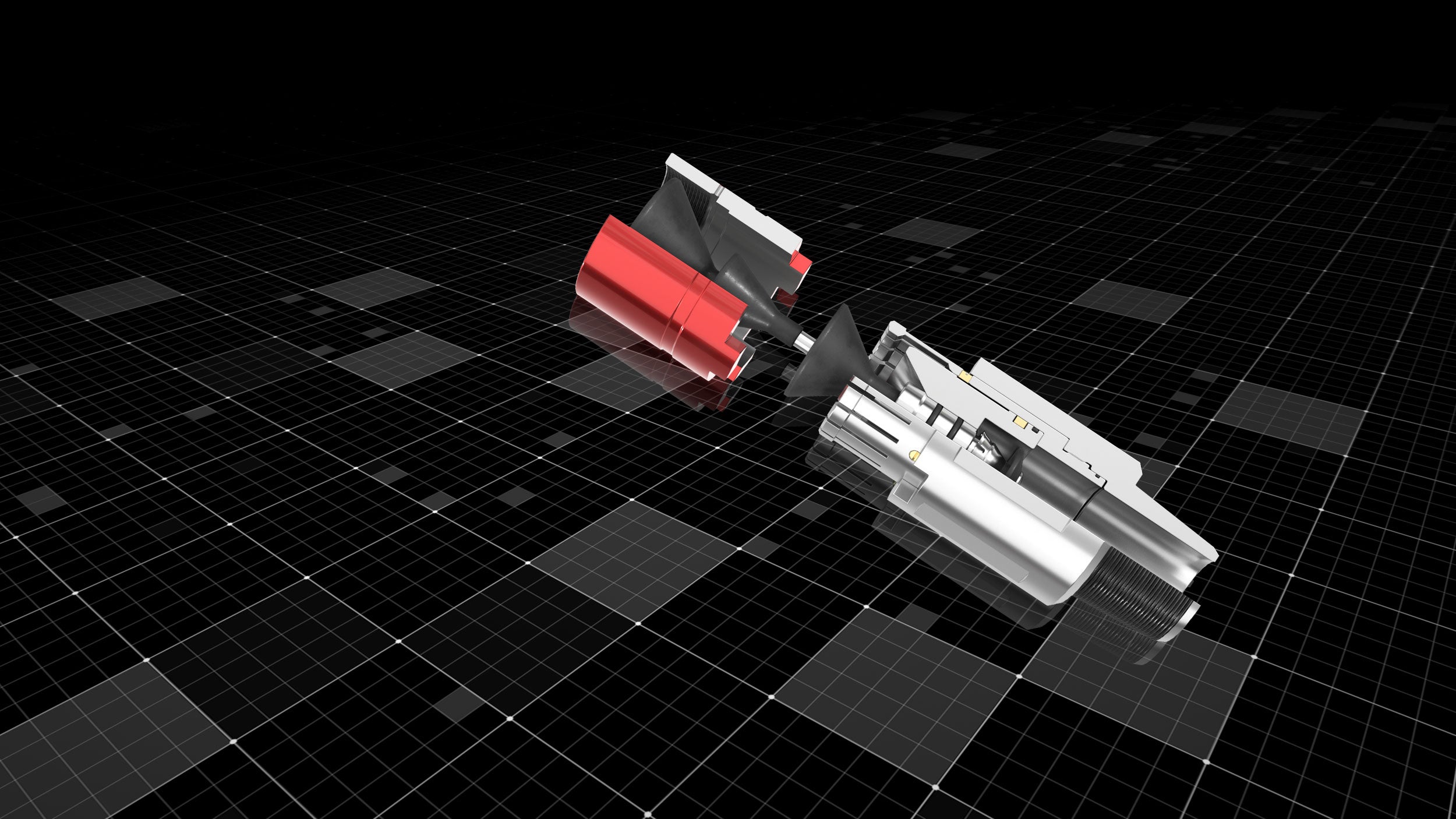

The Halliburton BHKA™ plug setting disconnect tool simplifies cement plug placement when necessary during well construction or abandonment operations.